Synthesis of magnetic nano-adsorbent material and application method thereof to the treatment of heavy metal waste liquid

An adsorption material and magnetic nanotechnology, applied in the field of environmental chemistry, can solve problems such as lack of adsorption capacity, achieve the effects of shortening treatment time, reducing sewage treatment costs, and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Add 1.5g FeCl to 50mL Erlenmeyer flask 3 ·6H 2 O. Mix 30mL ethylene glycol, 1.8g urea, and 0.35g EDTA, stir and dissolve at 50°C. After complete dissolution, the reaction solution was transferred to a 50mL high-temperature reactor, and reacted at 200°C for 6h. After the reaction, the obtained precipitate was separated from the reaction medium by an external magnetic field, and washed with deionized water several times successively to obtain Fe 3 o 4 Magnetic nanoparticles were precipitated, suspended in 150ml deionized water, and stored at 4°C for later use.

Embodiment 2

[0023] The prepared Fe 3 o 4 -EDTA, with Cu 2+ Optimizing the pH adsorption conditions for the adsorption object. see results figure 2 .

[0024] figure 2 , it can be seen from the figure that when the pH is 3-6, the adsorption capacity of the adsorbent increases with the increase of pH; when the pH is 6-9, the adsorption capacity reaches a plateau. It can be seen that the pH of the solution has a strong influence on the adsorption process, and the pH should be kept above 6 to perform complete adsorption; at the same time, when the pH<3, the adsorbent hardly has any adsorption, indicating that it can Regeneration of the adsorbent is achieved.

Embodiment 3

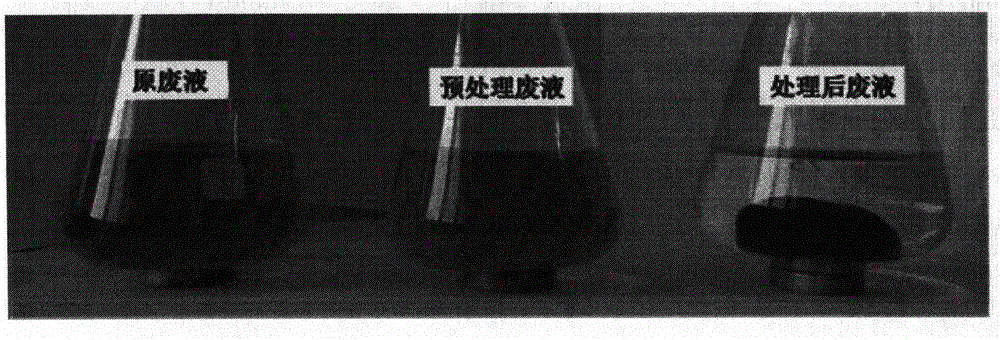

[0026] Treat the waste liquid produced by the COD detector according to the steps of reduction-adsorption. First, add reducing iron powder to the solution until there is insoluble iron powder. Shake for 1-3 minutes to make the reduction reaction fully. Adjust the pH to above 7, add magnetic nano-adsorption materials, shake for 5-10 minutes to make the adsorption reaction sufficient, and then use a magnet to adsorb the magnetic materials. see results image 3 , where a is the original waste liquid, the yellow color of the solution is caused by a large amount of dichromate in the solution; b is that after adding iron powder, the dichromate is reduced to Cr 3+ , the color presented is blue; c is the image of b solution mixed with the adsorbent in equal volume, and the metal ions in the solution are removed by magnet adsorption after adsorption. As can be seen from the figure, the supernatant was clear and transparent. After the supernatant was removed, the residual metal ion co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com