Epitaxial growth method for improving crystal quality of aluminum nitride material, and aluminum nitride material

An epitaxial growth and crystal quality technology, applied in crystal growth, polycrystalline material growth, single crystal growth and other directions, can solve the problems of good balance, low yield, poor uniformity, etc. Quality-improving, widely adaptable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] Example 1 Preparation of high-quality AlN epitaxial film on silicon substrate

[0080] S1. Substrate heat treatment: Put Si(111) substrate into MOCVD, 2 Under the atmosphere, raise the temperature to 1150°C, and then heat-treat for 5 minutes to remove the surface oxide layer.

[0081] S2. Pre-spread Al: reduce the growth temperature to 1050°C and maintain pure H 2 Under the conditions, the Al source is introduced, and a layer of Al is spread on the surface of the substrate to prevent NH 3 in contact with the substrate.

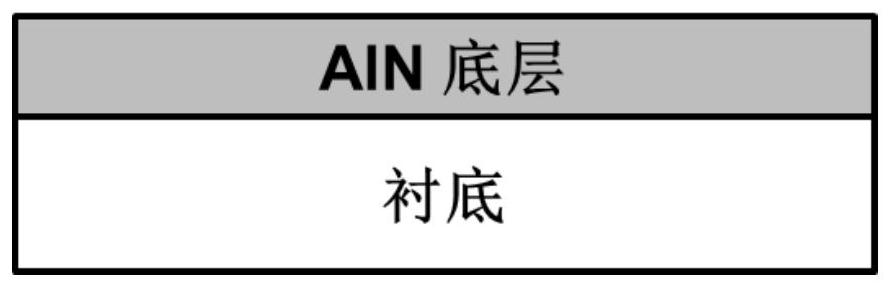

[0082] S3, growing the bottom layer of AlN: after laying Al, pass NH 3 , under the growth conditions of 1050°C, V / III of 200, and pressure of 50mbar, a 300nm AlN bottom layer was grown.

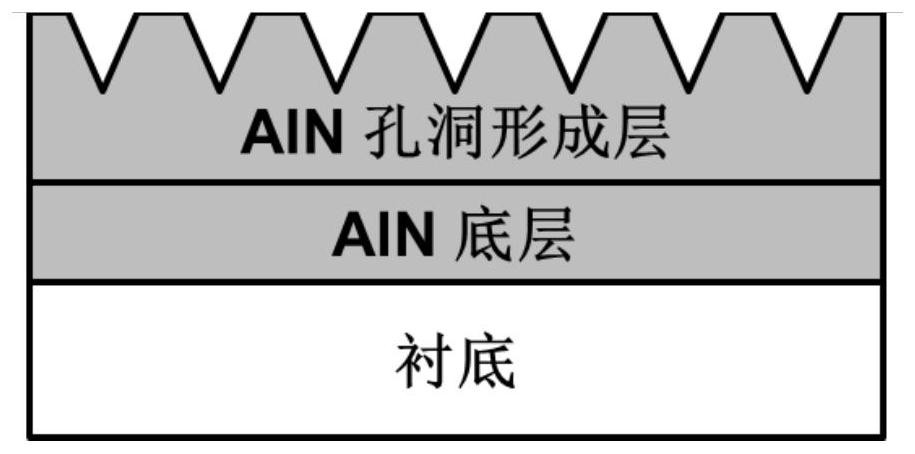

[0083] S4. Growth of AlN hole-forming layer: reduce the growth temperature to 850°C, increase V / III ratio to 2000, and pressure 100mbar, and grow 200nm AlN hole-forming layer at low temperature and high V / III to form diamond-shaped holes with crystal planes on the ...

Embodiment 2

[0086] Example 2 Preparation of high-quality AlN epitaxial film on planar sapphire substrate

[0087] S1. Sputtering an AlN bottom layer: On a sapphire substrate, sputter a 50nm AlN thin film as an AlN bottom layer.

[0088] S2. Put the AlN bottom layer into MOCVD, raise the temperature to 1150°C, and feed H at the same time 2 and NH 3 , annealed at high temperature for 10 minutes.

[0089] S3. Growth of AlN hole-forming layer: reduce the growth temperature to 900°C, increase the V / III ratio to 5000, and pressure 300mbar, and grow a 300nm AlN hole-forming layer at low temperature and high V / III to form diamond-shaped holes with crystal planes on the inner wall for The hole diameter is about 100nm.

[0090] S4. Growth of AlN merged layer: increase the growth temperature to 1200°C, reduce V / III ratio to 50, pressure 30mbar, grow 700nm AlN merged layer at high temperature and low V / III, and form voids inside the material, with an average width of 90nm , the vertical depth i...

Embodiment 3

[0093] Example 3 Preparation of high quality and high Al composition AlGaN epitaxial thin film on silicon substrate

[0094] S1. Substrate heat treatment: Put Si(111) substrate into MOCVD, 2 Under the atmosphere, raise the temperature to 1150°C, and then heat-treat for 5 minutes to remove the surface oxide layer.

[0095] S2. Pre-spread Al: reduce the growth temperature to 1050°C and maintain pure H 2 Under the conditions, the Al source is introduced, and a layer of Al is spread on the surface of the substrate to prevent NH 3 in contact with the substrate.

[0096] S3, growing the bottom layer of AlN: after laying Al, pass NH 3 , under the growth conditions of 1050°C, V / III of 200, and pressure of 50mbar, a 200nm AlN bottom layer was grown.

[0097] S4. Growing the bottom layer of AlGaN: on the basis of the bottom layer of AlN, pass NH at the same time 3 , Al source, Ga source, under the conditions of growth temperature of 1100°C, growth pressure of 100mbar, and growth V / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com