The scale-up preparation method, production equipment and stability evaluation method of special phenolic resin with narrow distribution and wide processing window

A technology of phenolic resin and formaldehyde, which is applied in the field of phenolic resin preparation, can solve the problems of many active sites, high reactivity, complex resin structure, composition and reaction route, etc., to ensure uniformity, improve mixing effect, and ensure measurement The effect of warm accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0100] As mentioned above, the present invention provides a method for stably preparing special phenolic resin with narrow distribution and wide processing window, which includes the following steps:

[0101] Step 1. Special phenolic resin addition and condensation reaction stage: control the preheating temperature of the raw material phenol in the feeding stage at 55±1°C, pump the phenol into the addition condensation reaction device through vacuum, and pump the formaldehyde into the metering tank; heat the phenol to 65±1°C, add catalyst and keep it warm for 30 minutes to keep the temperature of the material constant, start adding formaldehyde dropwise, complete the dropwise addition of formaldehyde within 60±5 minutes, and then raise the material to 90±1°C within 40±5 minutes , the heat preservation reaction is about 3 hours, the refractive index is 1.5250-1.5370, and the addition condensation reaction is completed;

[0102] Step 2, neutralization reaction stage: After the a...

Embodiment A-1

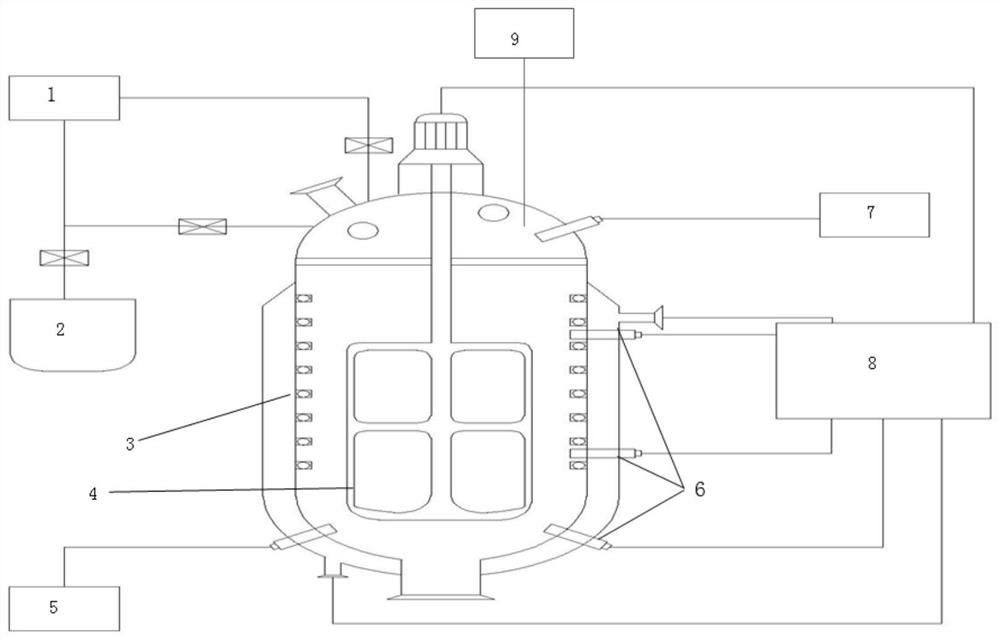

[0109] Addition condensation reaction device for the expansion of special phenolic resins, such as figure 1 As shown, it includes a kettle body, an online viscometer, a temperature control unit (TCU) 8, a temperature measuring point 6, a stirring mechanism and a vacuum unit 7.

[0110] The volume of the kettle body is 3m 3 , the top of the kettle body is provided with a feeding port, the feeding port is connected with the formaldehyde dripping tank 9, the kettle body adopts the temperature control mode of inner coil pipe 3 heating, reactor jacket cooling, valve switch switchable, to improve the heating and cooling of materials efficiency.

[0111] The stirring mechanism of the addition condensation reaction device is a three-layer frame stirring 4, which can improve the mixing effect of the materials and the uniformity of the temperature of the materials.

[0112] The addition condensation reaction device adopts "upper-middle-lower" three-point temperature measurement, and t...

Embodiment A-2

[0117] The production system for the expansion preparation of special phenolic resins includes the addition condensation reaction device, filter mechanism, metering tank and feeding tank in Example A-1, and an optional independent dehydration reaction kettle. The structure of the independent dehydration reaction tank is the same as that of the addition condensation reaction device. The filtering mechanism is arranged outside the addition-condensation reaction kettle, and is used for filtering the reaction materials obtained in the neutralization reaction stage. After the reaction material obtained in the neutralization reaction stage is filtered by the filter mechanism, it can be returned to the addition condensation reaction kettle for dehydration reaction. At this time, the addition condensation reaction kettle becomes a dehydration reaction kettle; or enters an independently set dehydration reaction kettle .

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com