Rotary excavating device and rotary excavating method

A technology for excavating devices and rotating sleeves, which is applied in mining devices, shaft equipment, earthwork drilling and mining, etc., and can solve problems such as failure of normal jacking, increased construction costs, and stuck pipe jacking machine cutter head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

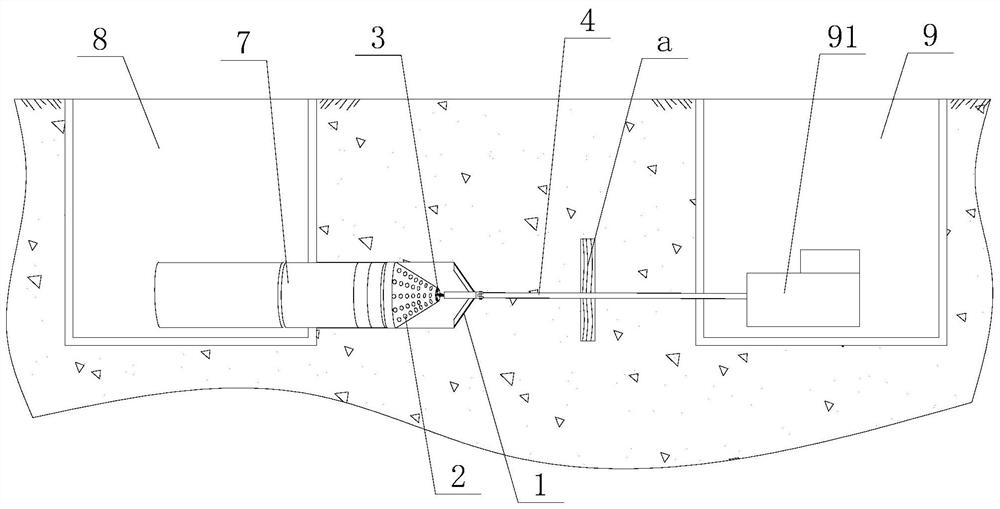

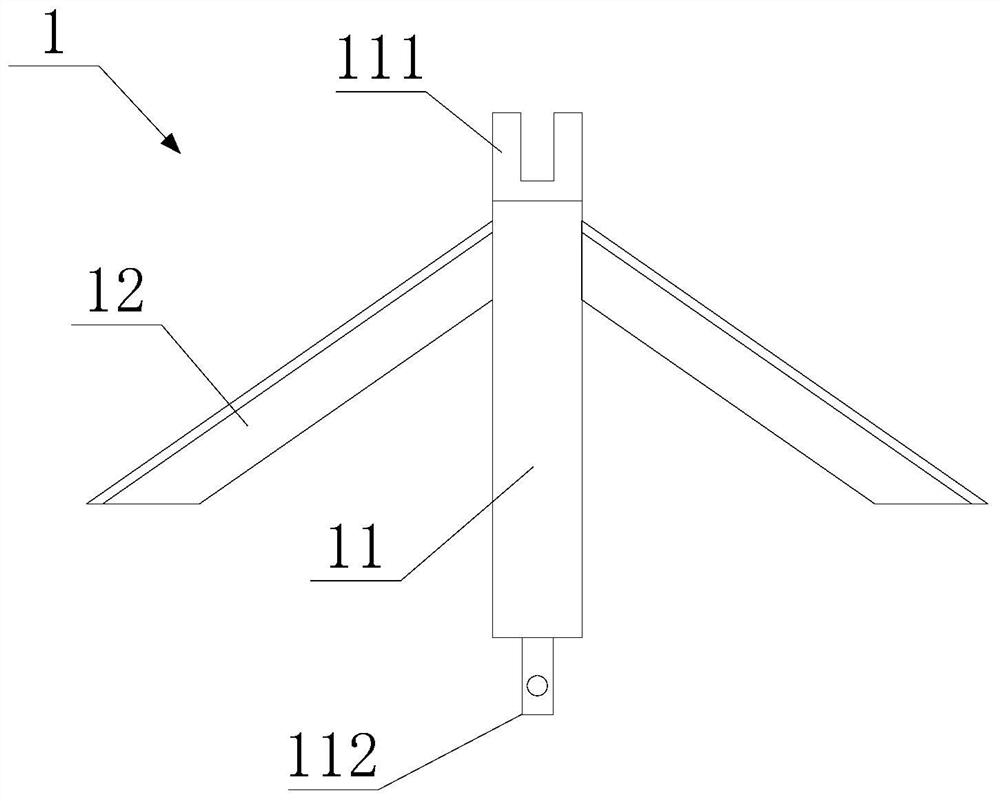

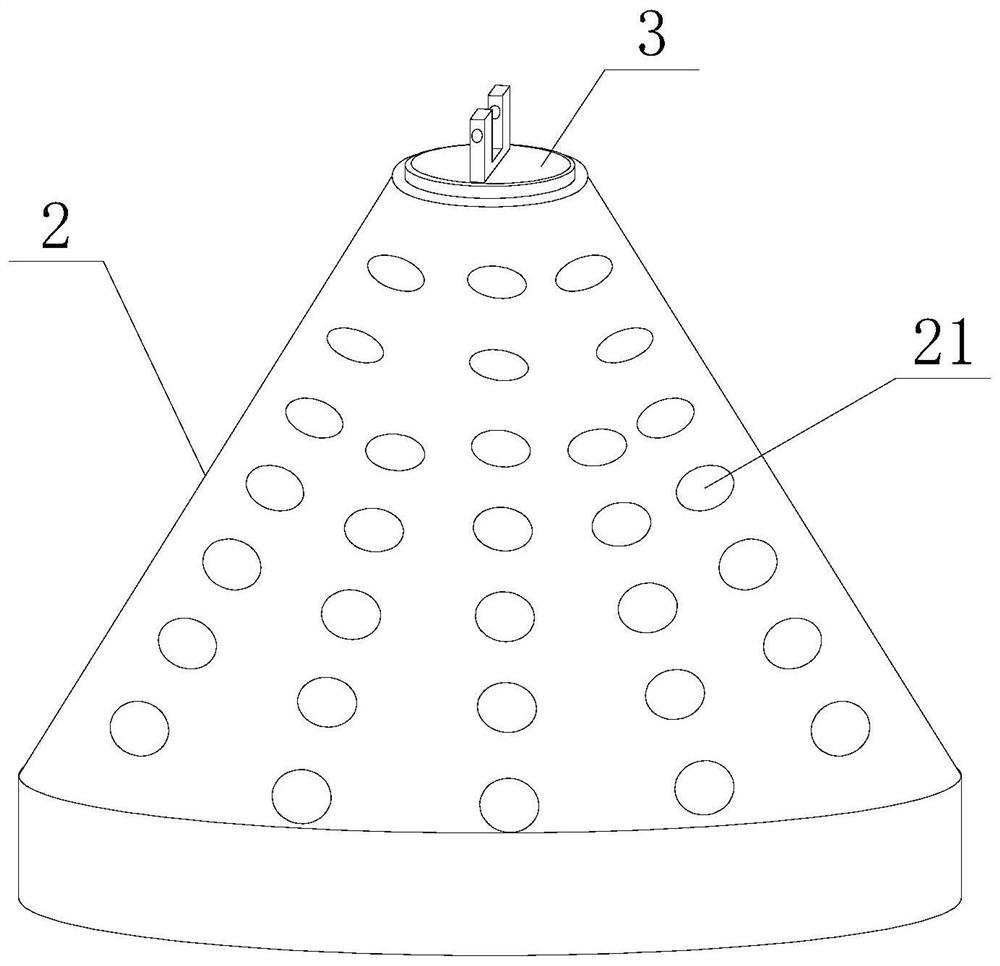

[0034] Figure 1 to Figure 6 An embodiment of the rotary excavating device of the present invention is shown, the rotary excavating device includes a planing mechanism 1 and a conical rotary head cap 2, the side wall of the rotary head cap 2 is provided with a mud inlet and outlet hole 21, The tip of the rotating machine head cap 2 is provided with a rotatable and telescopic connecting head 3, and the planing mechanism 1 includes a rotating central axis 11 and at least two strip-shaped planing knives 12, and one end of the rotating central axis 11 and the connecting head 3 can be Detachably connected, the other end is provided with the connecting portion 111 that is used to be connected with drill pipe 4, and one end of planer cutter 12 is fixed on the rotating central axis 11, and the other end is inclined toward rotating machine hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com