Intelligent polishing equipment for half shaft of electric vehicle

A technology for electric vehicles and equipment, applied in the direction of grinding/polishing equipment, metal processing equipment, surface polishing machine tools, etc., can solve the problems of polishing powder splashing everywhere, difficult to clean equipment, affecting equipment operation performance and product quality, etc., to achieve Improve the cleaning effect and avoid the effect of irregular splashing of iron filings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

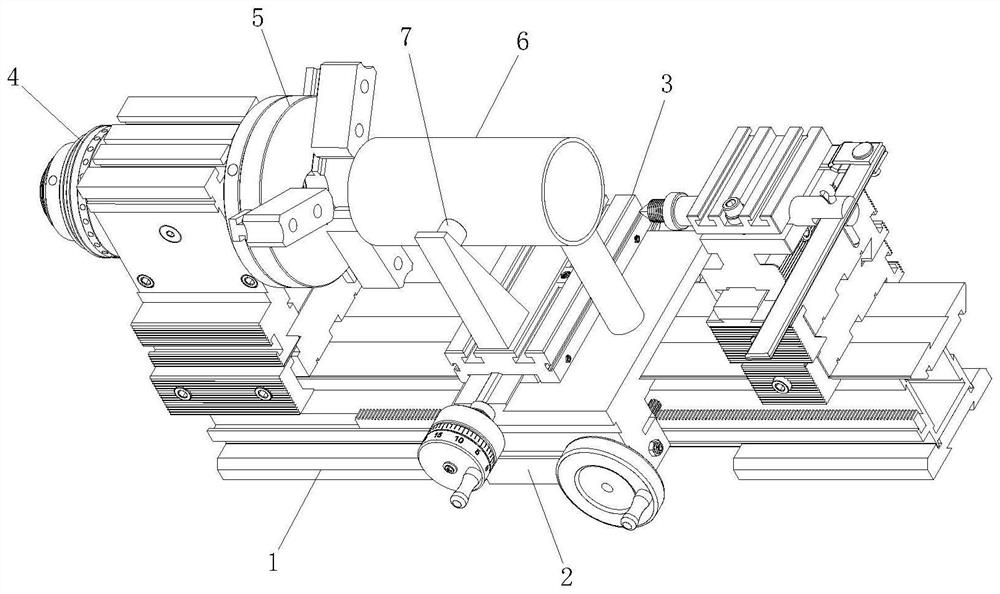

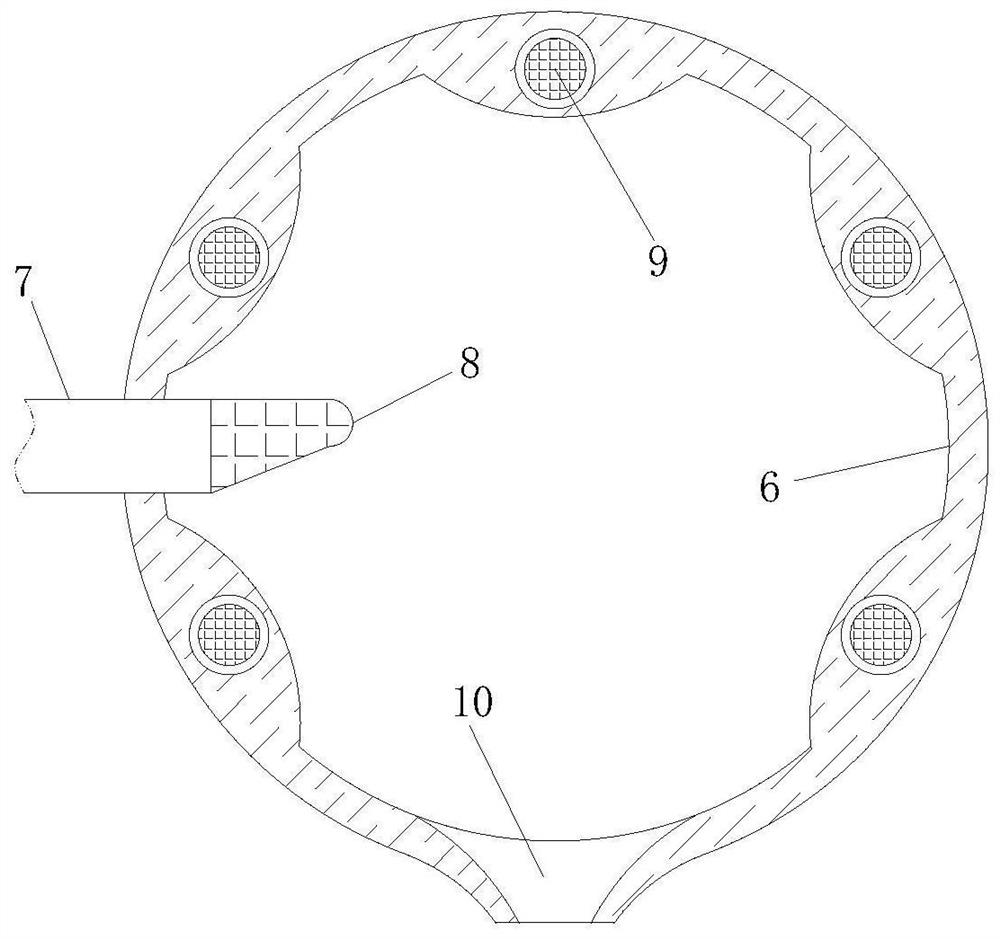

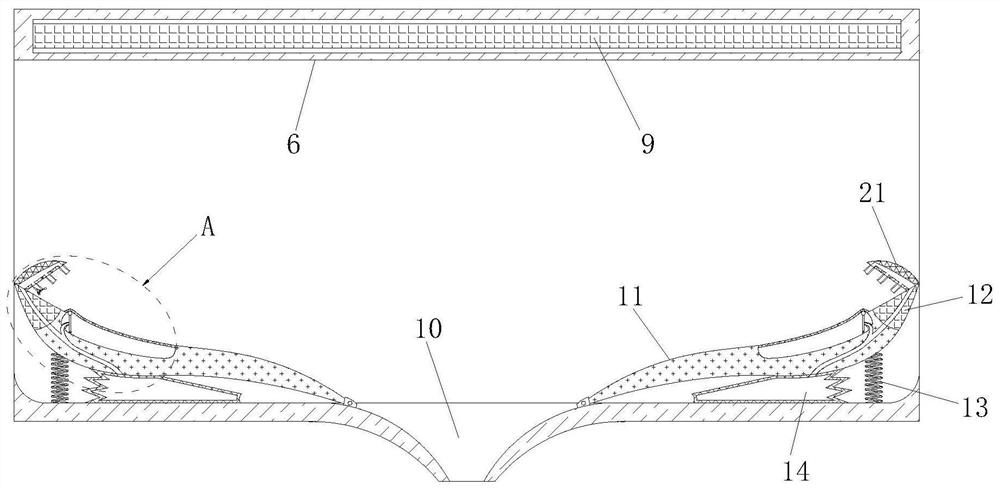

[0030] like Figure 1 to 5As shown, an electric vehicle is half-axis intelligent polishing apparatus according to the present invention, including a base 1; the upper side of the base 1 is slid with one operating table 2; the upper side slide connection is slid. No. 3; The upper side of the base 1 is mounted on the upper side, and the clamp disk 5 is driven by the motor 4; the upper side of the first operating table 2 is secured by the stent 6, and the sleeve The cartridge 6 is concentric with the clamp disk; the upper side of the secondary operating table 3 is fixed to the push rod 7, and the push rod 7 is slidable with the sleeve 6; the push rod 7 extends to one end in the sleeve 6. Solid-mounted with a grinding head 8; an electromagnet strip 9 is mounted in the inner wall of the sleeve 6; the sleeve 6 is opened at the bottom of the sleeve 6; mounting the car half shaft on the clamp disk 5, and half-axis The tank 6, the start motor 4 drives the half-axis rotation while the electr...

Embodiment 2

[0039] like Image 6 As shown, Comparative Example 1, as another embodiment of the present invention, the sprout 29 is rotated from the spray head 23 away from the magnetic block 12; the twirling 29 extends to one end of the nozzle 23 There is a split block 30; a plurality of dispersion type passages 31 are opened in the split block 30; the airflow is pushed through the spray head 23 to rotate, which in turn drives the splitting block 30 to rotate, the dispersion type passage 31 and the sprinkal block 30 will flow airflow Dispersion, accompanying the rotation of the split block 30, generating a spiral flow, an increase in the range of the gas stream, thereby increasing the gas flow to the cleaning area of the tomato block 11.

[0040] Sliding sealing in the outlet end of the dispersion type passage 31 has barrier ball 32; the barrier ball 32 is fixed to the inner side wall of the dispersion type passage 31, and there is an elastic strip 33; when the gas flow is passed, the airflo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com