A low temperature resistant flexible thermoelectric material, thermal battery and preparation method thereof

A low-temperature flexible, thermoelectric material technology, applied in secondary batteries, circuits, electrothermal devices, etc., can solve problems such as hindering redox electrothermal migration, affecting thermoelectric conversion efficiency, and limiting the application of thermal batteries, so as to facilitate mass production and improve Freeze resistance and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

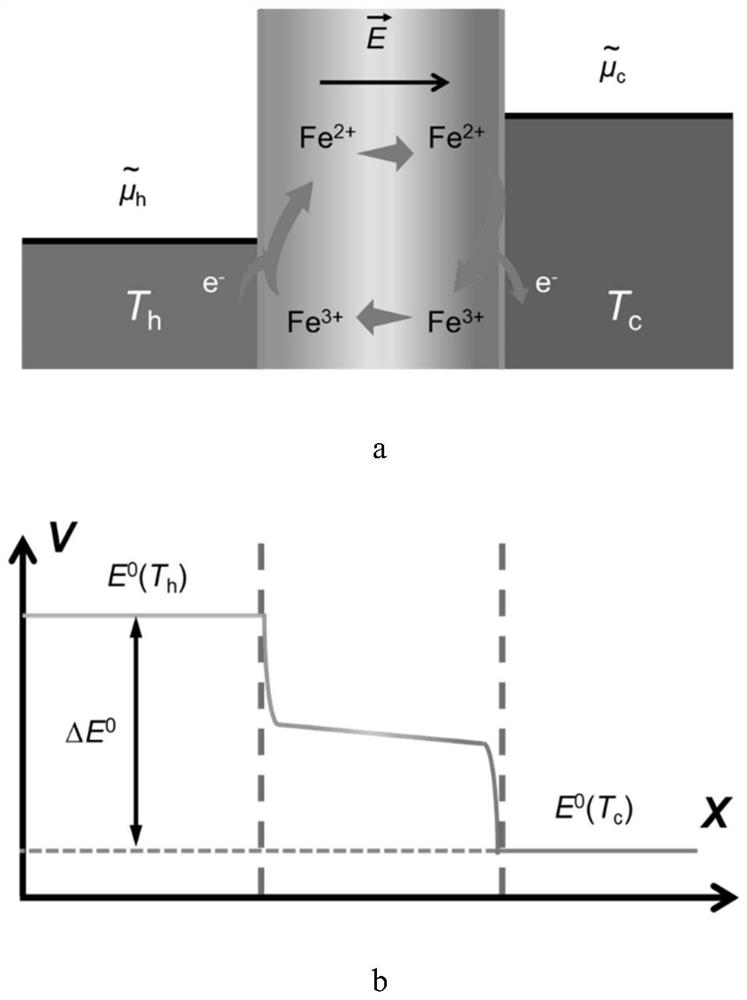

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Take 4 wt% of acryloyloxyethyltrimethylammonium chloride monomer and 20 wt% of acrylamide monomer, the total mass of monomers 1 wt% polyethylene glycol acrylic acid crosslinking agent and the total mass of monomers 0.2 The mol% ammonium persulfate initiator was dissolved in deionized water to obtain a precursor solution. The precursor solution was poured into shaped molds of different shapes, degassed and sealed, and reacted in a steady state at 60 °C for 12 h to complete the polymerization to obtain flexible stretchable matrices of different sizes (rectangular, square, circular, fibrous). Soak the prepared flexible stretchable matrix in a mixture of 0.18 M ferric chloride / 0.18 M ferric chloride / 50% ethylene glycol / 50% water for solvent exchange, and prepare flexible thermoelectric materials resistant to low temperature, such as figure 2 shown. The Seebeck coefficient of low temperature resistant flexible thermoelectric materials is as follows image 3 shown, for 2 mV ...

Embodiment 2

[0051] Take 4 wt% of acryloyloxyethyltrimethylammonium chloride monomer and 20 wt% of acrylamide monomer, the total mass of monomers 1 wt% polyethylene glycol acrylic acid crosslinking agent and the total mass of monomers 0.2 The mol% ammonium persulfate initiator was dissolved in deionized water to obtain a precursor solution. The precursor solution was poured into shaped molds of different shapes, degassed and sealed, and reacted in a steady state at 60 °C for 12 h to complete the polymerization to obtain thermal battery substrates of different sizes (rectangular, square, circular, fibrous). The prepared thermal battery substrate was soaked in a mixture of 0.3 M potassium ferricyanide / 0.3 M potassium ferrocyanide / 66 % glycerol / 33 % water for solvent exchange, and a low temperature resistant flexible organic oil gel was prepared. A low-temperature resistant flexible thermal battery was prepared by integrating copper electrodes at both ends of the organic oil gel. Its Seebeck...

Embodiment 3

[0054] Take 3 wt% of acryloyloxyethyltrimethylammonium chloride monomer and 20 wt% of acrylamide monomer, the total mass of monomers 1 wt% polyethylene glycol acrylic acid crosslinking agent and the total mass of monomers 0.2 The mol% ammonium persulfate initiator was dissolved in deionized water to obtain a precursor solution. The precursor solution was poured into shaped molds of different shapes, degassed and sealed, and reacted in a steady state at 60 °C for 12 h to complete the polymerization to obtain thermal battery substrates of different sizes (rectangular, square, circular, fibrous). The prepared thermal battery substrate was soaked in a mixture of 0.5 M ferric chloride / 0.5 M ferrous chloride / 66 % ethylene glycol / 33% water for solvent exchange, and a low temperature resistant flexible organic oil gel was prepared. A low-temperature resistant flexible thermal battery was prepared by integrating copper electrodes at both ends of the organic oil gel. Its Seebeck coeffi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com