Stator glue pouring tool and stator glue pouring method based on same

A stator and glue filling technology, which is applied in the manufacture of stator/rotor bodies, electromechanical devices, cooling/ventilation devices, etc., can solve the problems of reduced service life of the motor, unsatisfactory heat dissipation effect, and aging of the coil insulation layer, so as to reduce service failures The effect of shortening the glue filling process cycle and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

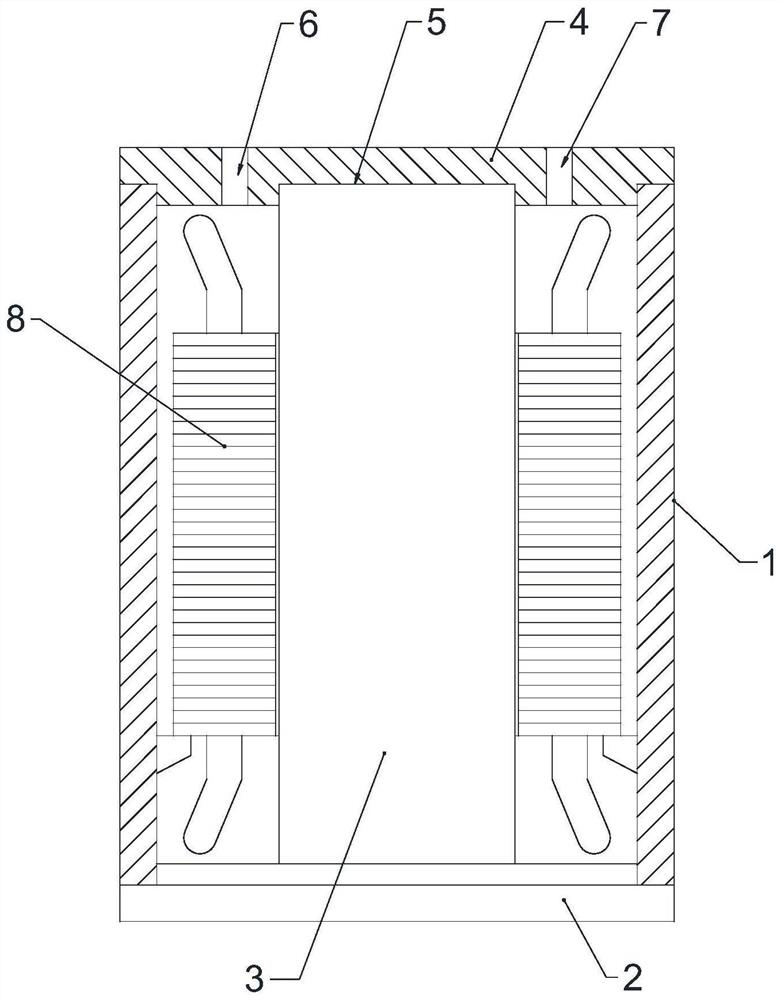

[0032] Such as figure 1 The stator glue filling tool shown includes a lower sealing plate 2 that is closed and docked with one end of the motor housing 1, a mold column 3 that is vertically connected to the lower sealing plate 2 and plugged into the center of the motor housing 1, and is connected to the motor housing 1. The other end of the housing 1 is closed to the butted upper sealing plate 4, and the upper sealing plate 4 is provided with a groove 5 matching with the mold column 3, and the mold column 5 is inserted into the groove 5 on the upper sealing plate 4, and the upper sealing plate 4 The sealing plate 4 is additionally provided with an upper glue hole 6 and an exhaust hole 7 .

[0033] In this embodiment, the outer diameter of the mold column 3 is preferably larger than the outer diameter of the rotor and smaller than the inner diameter of the stator 8, so that a layer of glue can be formed on the inner hole wall of the stator to improve the anti-corrosion performa...

Embodiment 2

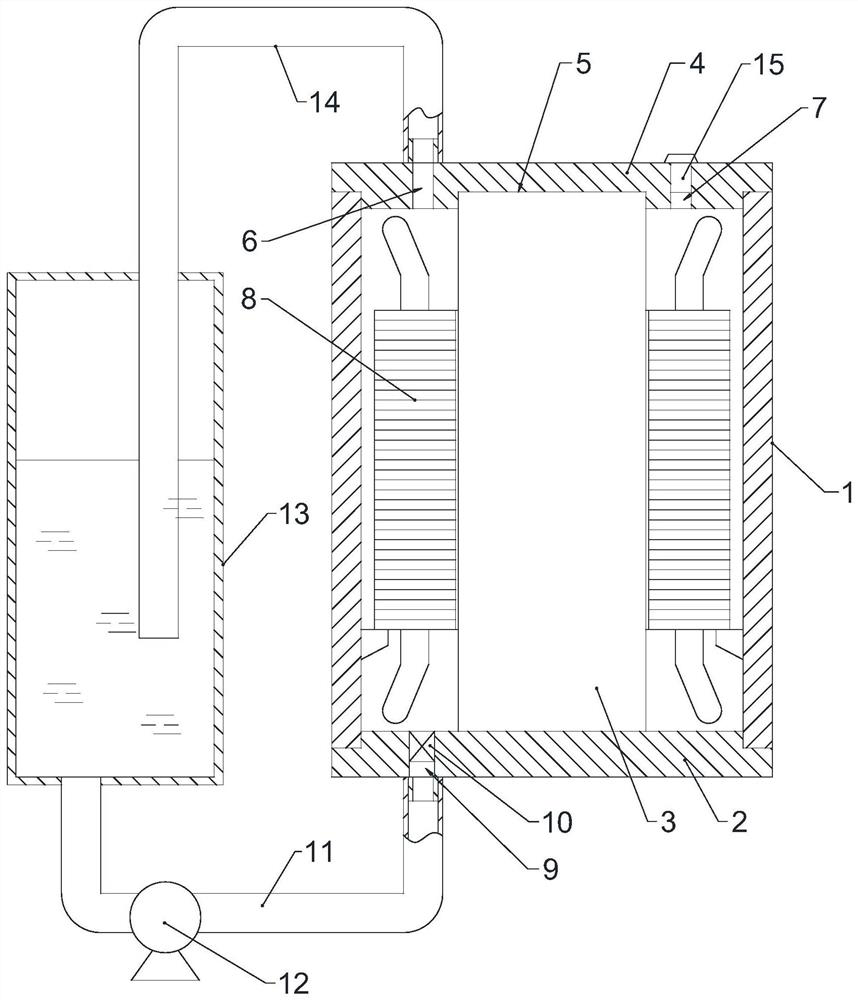

[0042] Embodiment 2: as figure 1 The stator glue filling tool shown includes a lower sealing plate 2 that is closed and docked with one end of the motor housing 1, a mold column 3 that is vertically connected to the lower sealing plate 2 and plugged into the center of the motor housing 1, and is connected to the motor housing 1. The other end of the housing 1 is closed to the butted upper sealing plate 4, and the upper sealing plate 4 is provided with a groove 5 matching with the mold column 3, and the mold column 5 is inserted into the groove 5 on the upper sealing plate 4, and the upper sealing plate 4 The sealing plate 4 is additionally provided with an upper glue hole 6 and an exhaust hole 7 .

[0043] The lower sealing plate 2 is provided with a lower glue hole 9, and a leak-proof check valve 10 can be arranged in the lower glue hole 9. A pump hose 11 is detachably connected to the lower glue hole 9, and the pump hose 11 passes through the pump. The body 12 communicates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com