Positive electrode material, preparation method thereof and secondary lithium battery

A technology of positive electrode materials and elements, applied in the field of high-nickel ternary positive electrode materials and its preparation, can solve the problems of increasing the complexity of the precursor preparation process, high requirements for process stability control, increasing mixing and heat treatment, and achieving safe large-scale Industrialized production, improving the stability of material structure, and inhibiting the effect of material phase transition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

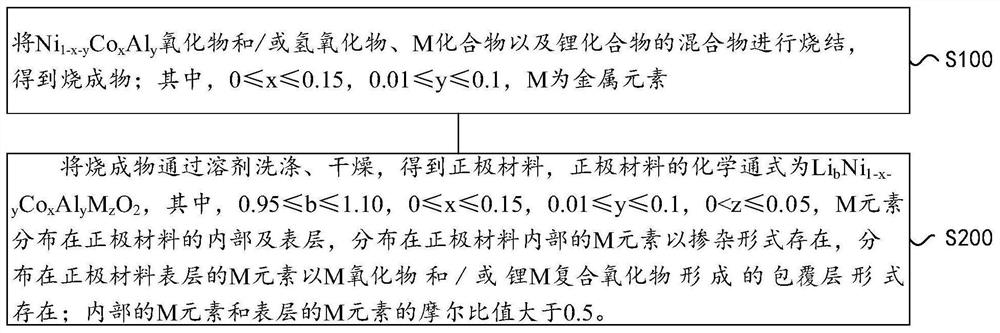

[0084] In the second aspect, the embodiment of the present application also provides a method for preparing a positive electrode material, such as figure 1 As shown, the following steps S100-S200 are included:

[0085] Step S100, will contain Ni 1-x-y co x al y The mixture of oxide and / or hydroxide, M compound and lithium compound is sintered to obtain a fired product; wherein, 0≤x≤0.15, 0.01≤y≤0.1, and the M element is a metal element;

[0086] Step S200, washing and drying the calcined product with a solvent to obtain the positive electrode material, the general chemical formula of the positive electrode material is Li b Ni 1-x-y co x al y m z o 2 , wherein, 0.95≤b≤1.10, 0≤x≤0.15, 0.01≤y≤0.1, 0<z≤0.05, the M element is distributed in the interior and surface layer of the positive electrode material, and the M element distributed in the positive electrode material The M element exists in the form of doping, and the M element distributed on the surface of the positive...

Embodiment 1

[0120] In this embodiment, the positive electrode material is prepared according to the following method:

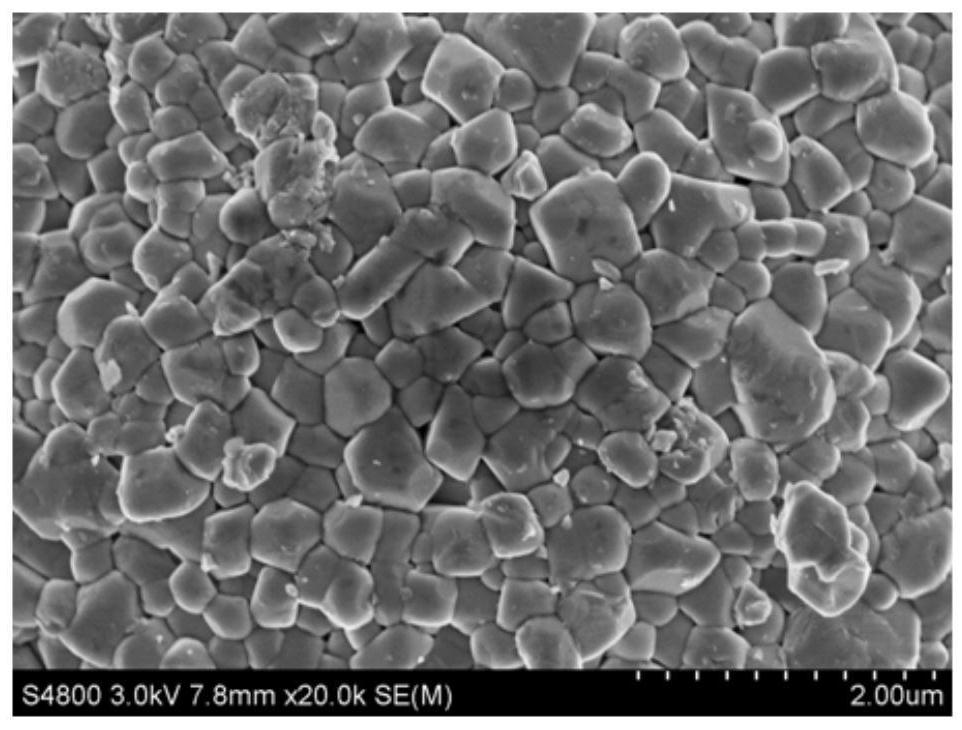

[0121] (1) First, the Ni 0.88 co 0.09 Al 0.03 o 2 Oxide, lithium hydroxide and Mg(OH) with a D50 of 2.5 μm 2 Mix evenly in a high-mixer (Li / (Ni+Co+Al+Mg)=1.08, Mg is 3000ppm), and finally sinter the above mixture at 760°C in an atmosphere of 95% oxygen+5% nitrogen for 10 hours, and then pulverize Sieve to obtain Mg-modified calcined Li 1.08 Ni 0.88 co 0.09 Al 0.03 Mg 0.013 o 2 .

[0122] (2) The above-mentioned fired material Li 1.08 Ni 0.88 co 0.09 Al 0.03 Mg 0.013 o 2 with containing 1.5wt% H 3 PO 4 The aqueous solution according to the slurry concentration of 1000g / L (fired product (g) / H 3 PO 4 Aqueous solution (L)) is mixed into a slurry, then washed, filtered, and dried to obtain the positive electrode material LiNi 0.88 co 0.09 Al 0.03 Mg 0.013 o 2 , its average particle size is 12.5μm, D95 is 21.3μm, specific surface area is 1.13m 2 / g

...

Embodiment 2

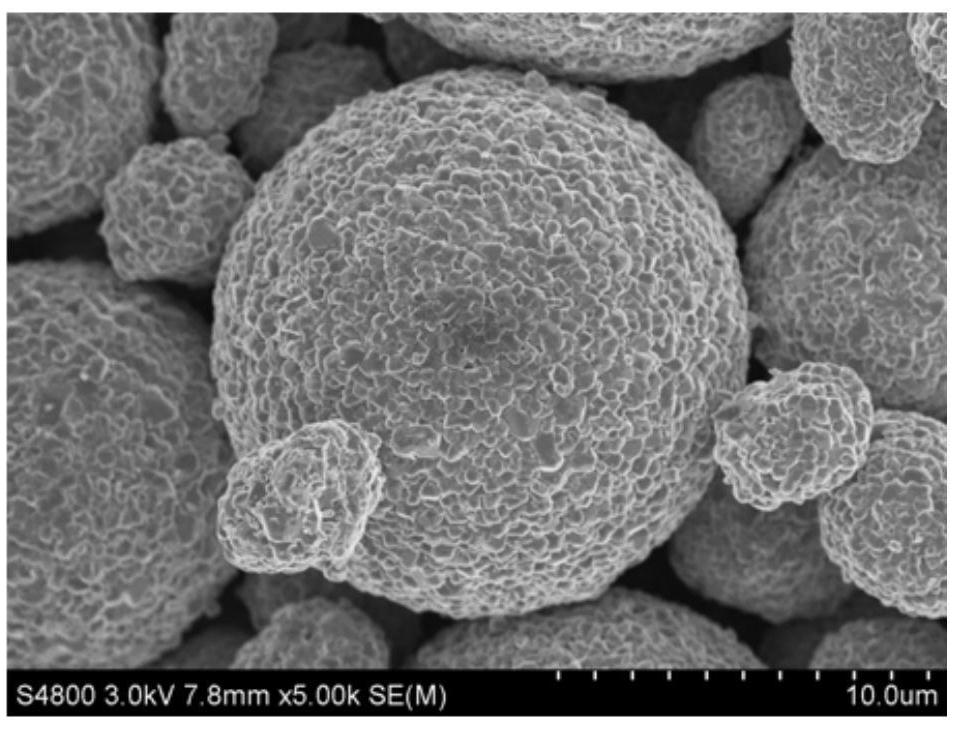

[0125] In this embodiment, the positive electrode material is prepared according to the following method:

[0126] (1) First, the Ni 0.76 co 0.15 Al 0.09 (OH) 2 Calcined hydroxide, lithium hydroxide and Mg(OH) with a D50 of 2.5 μm 2 Mix evenly in a high-mixer (Li / (Ni+Co+Al+Mg)=1.10, Mg is 1000ppm), and finally sinter the above mixture at 850°C in an atmosphere of 90% oxygen+10% nitrogen for 26 hours, and then pulverize Sieve to obtain Mg-modified calcined Li 1.10 Ni 0.76 co 0.15 Al 0.09 Mg 0.004 o 2 .

[0127] (2) The above-mentioned fired material Li 1.10 Ni 0.76 co 0.15 Al 0.09 Mg 0.004 o 2 with containing 1.0wt% H 3 PO 4 The aqueous solution according to the slurry concentration of 500g / L (fired product (g) / H 3 PO 4 Aqueous solution (L)) is mixed into a slurry, then washed, filtered, and dried to obtain the positive electrode material LiNi 0.76 co 0.15 Al 0.09 Mg 0.004 o 2 , its average particle size is 15.3μm, D95 is 24.6μm, specific surface area i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com