Active heat dissipation structure of flip-chip bonding device and interconnection method

A heat dissipation structure and active technology, which is applied in the manufacturing of electric solid state devices, semiconductor devices, and semiconductor/solid state devices, etc., can solve the problems of low heat dissipation efficiency of passive heat sinks, affecting the performance of chips, and hindering heat conduction of chips. Heat sink breakage problem, shrinking circuit package size, and the effect of small heat sink area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

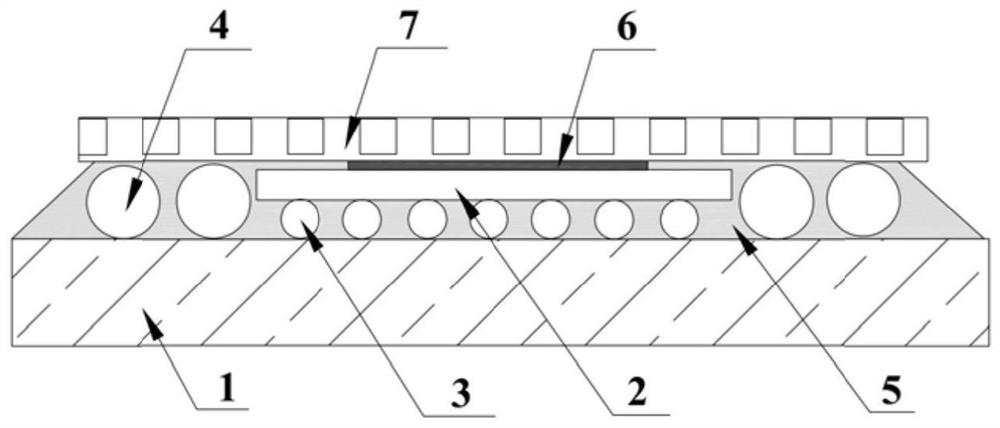

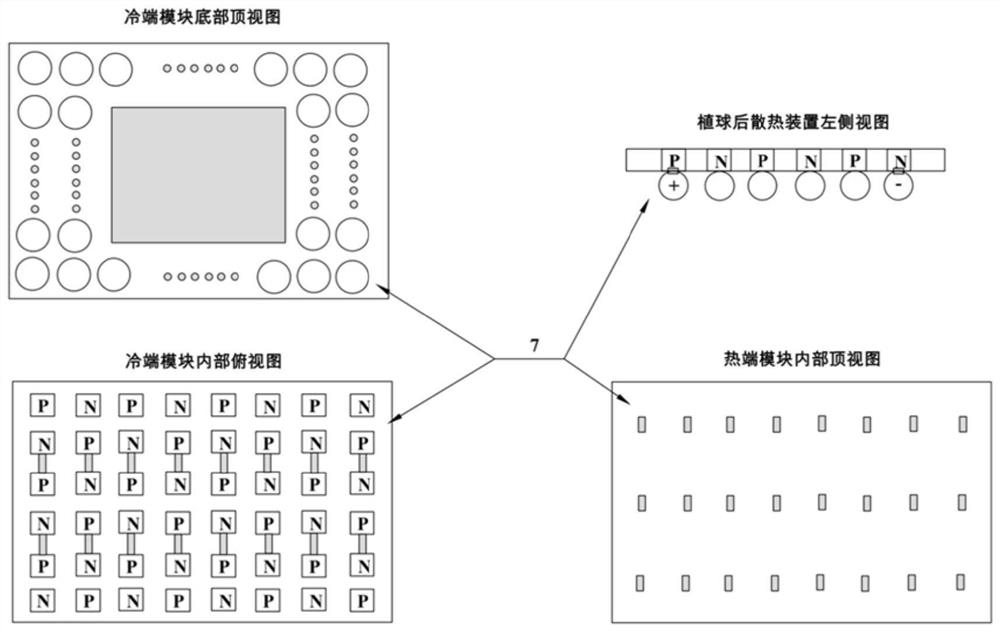

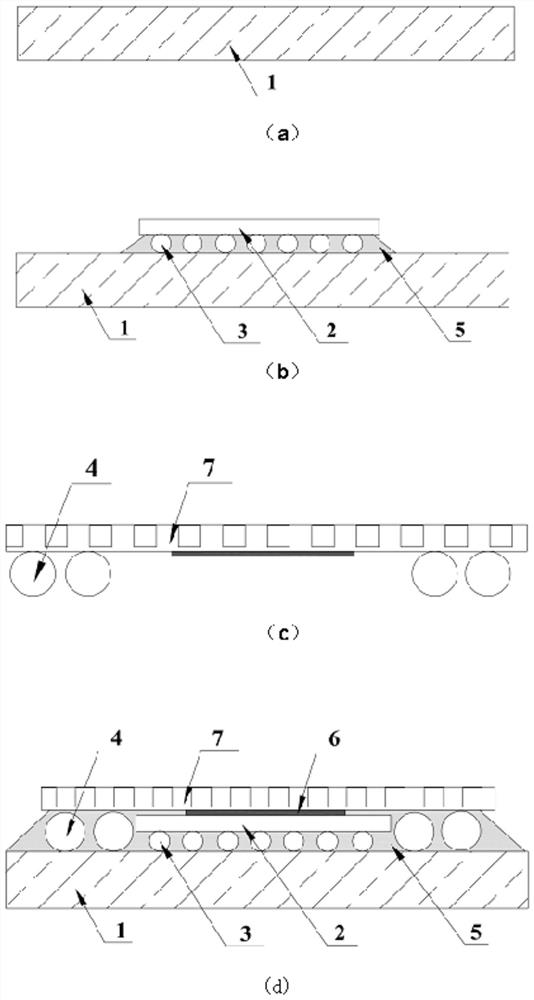

[0040] An active heat dissipation structure and interconnection method for flip-chip soldering devices. The active heat dissipation method is adopted without additional auxiliary heat dissipation, and the heat dissipation efficiency is high. The working temperature environment of the chip can be optimized, and the service life of the chip can be improved. It hinders the heat conduction of the chip and causes a higher junction temperature, which affects the performance of the chip. The active heat dissipation structure of the flip-chip device is specifically:

[0041] Including packaging substrate, flip chip, electrical interconnection material, electrical interconnection material, underfill glue, heat sink, and heat dissipation device, the electrical interconnection material is arranged on the front of the flip chip, and the flip chip is flip mounted on the packaging substrate. The underfill adhesive is bonded and fixed, the central area of the bottom of the heat sink is conn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com