Method for predicting residual life of gearbox bearing

A prediction method, gear box technology, applied in neural learning methods, testing of mechanical components, testing of machine/structural components, etc., can solve the inaccurate life prediction results, do not consider other types such as current signal sensors, do not consider To solve problems such as the results of the coupling effect of components, to achieve the effect of strengthening feature extraction and screening capabilities, improving prediction accuracy, and avoiding deep damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with embodiment the present invention is described in further detail:

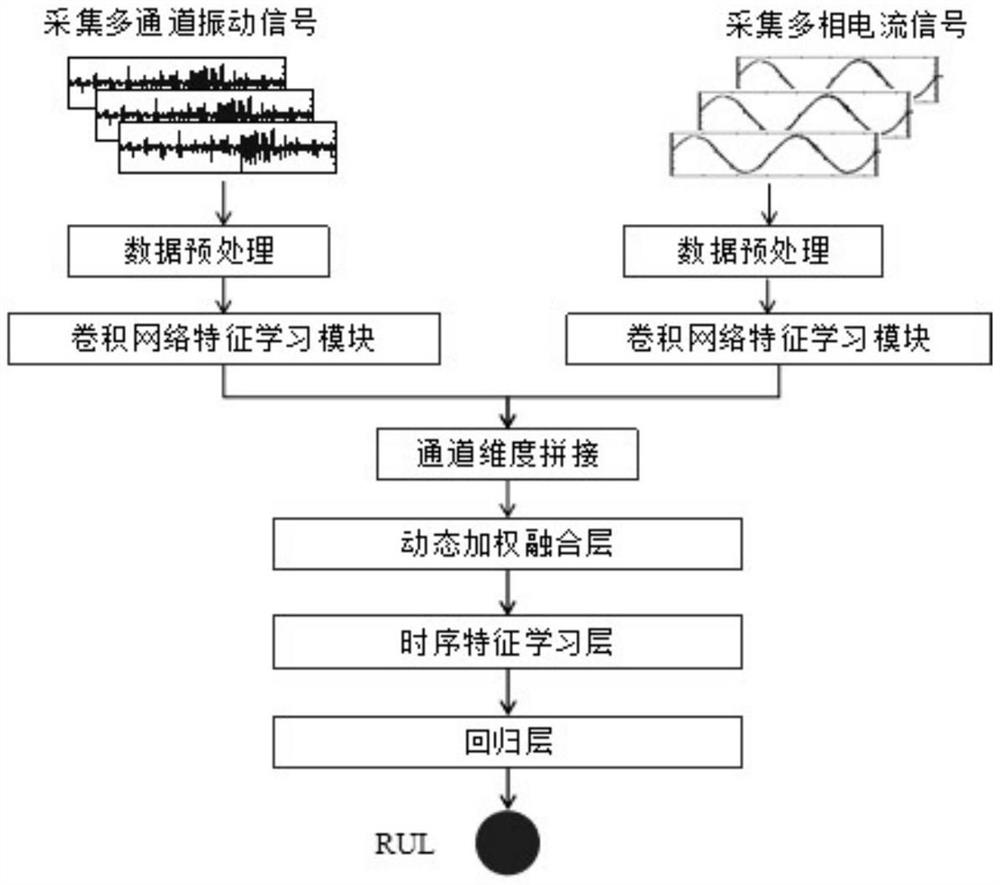

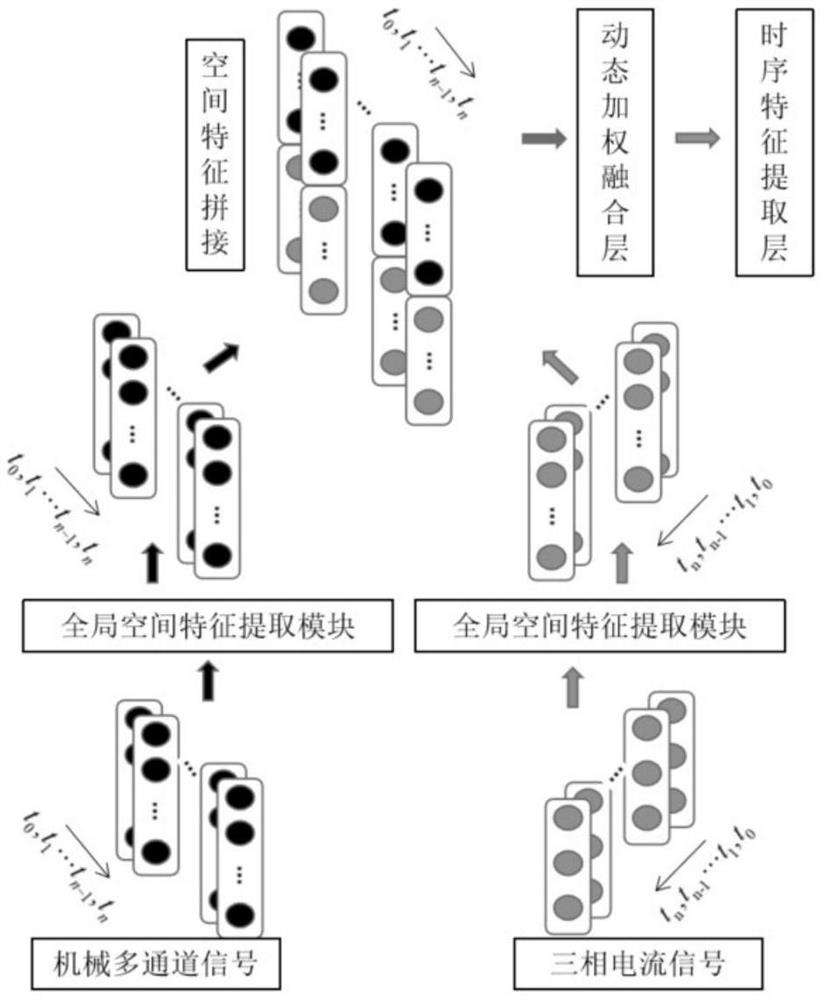

[0038] Such as figure 1 As shown, a method for predicting the remaining life of gearbox bearings includes the following steps:

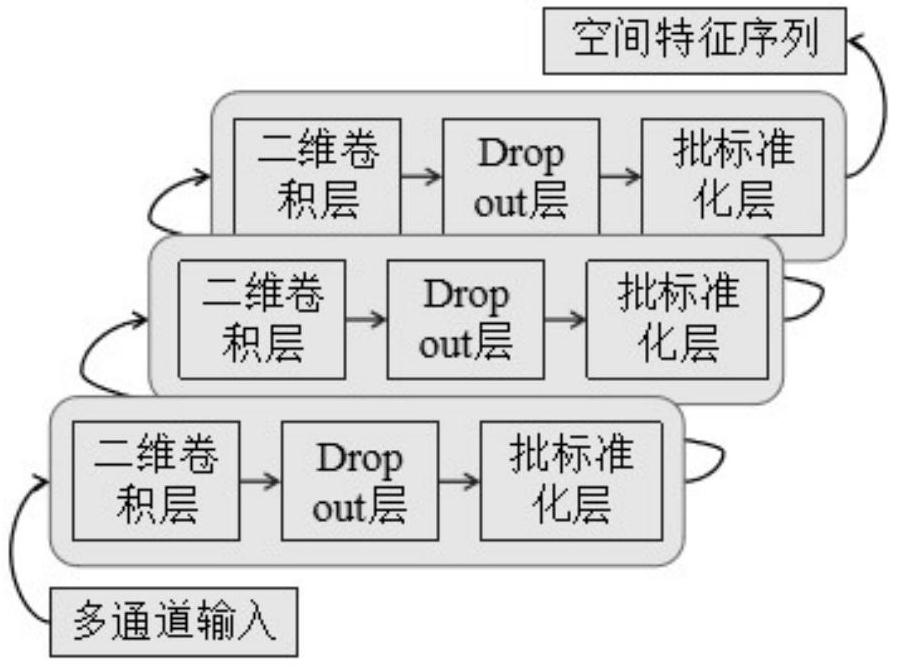

[0039] Step S1: Step S11, use the acceleration sensor to collect the multi-channel vibration signal of the gearbox bearing, obtain the multi-channel stator current signal from the generator output terminal through the current clamp, obtain the original multi-channel vibration signal and the multi-channel stator current signal, and perform data preprocessing;

[0040] Step S12, perform equidistant indexing on the data in time series to reduce the amount of data, and the step size is M;

[0041] Step S13, perform sliding window processing to fully extract time series feature information, the window size is W, and after further normalization processing of maximum and minimum values, the finally obtained data size is:

[0042] N 1 / (M*W)×1×D 1 ,N 2 / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com