Method for measuring zinc element in electroslag steel by ICP-OES

A determination method and element technology, applied in the direction of material excitation analysis, thermal excitation analysis, etc., can solve the problems that are not conducive to the safety and health of operators, the detection data is not fast and convenient, and the time required for sample analysis is long, etc., to achieve a clear and clear dissolution effect. Save manpower and material resources, low detection limit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

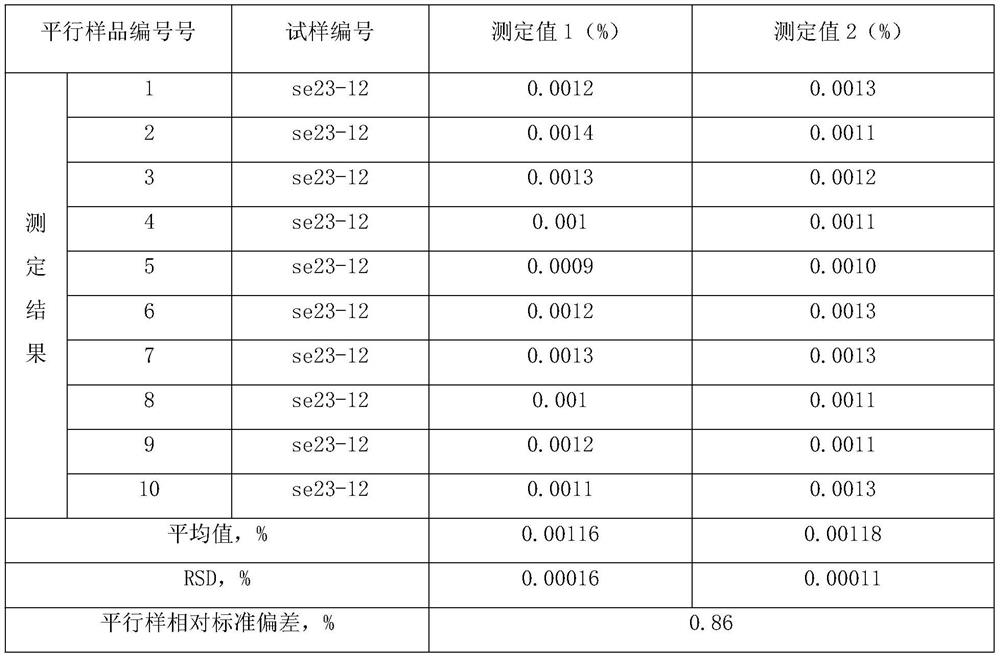

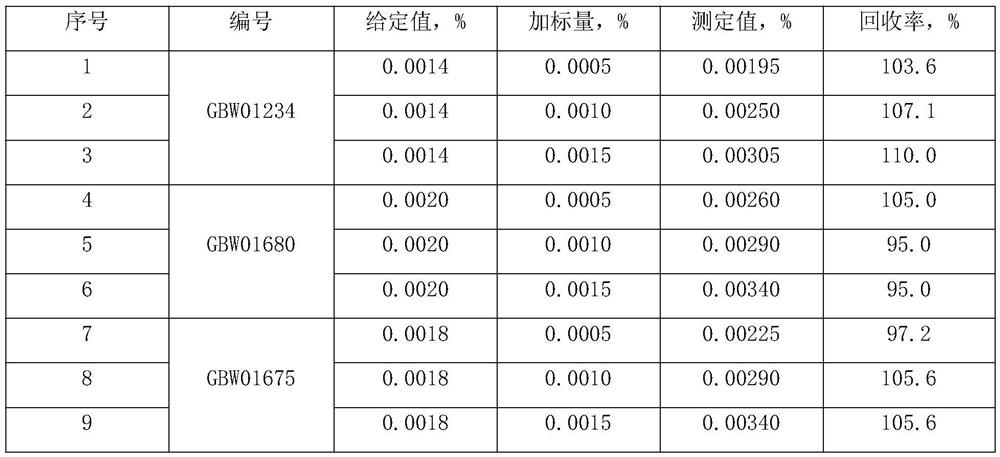

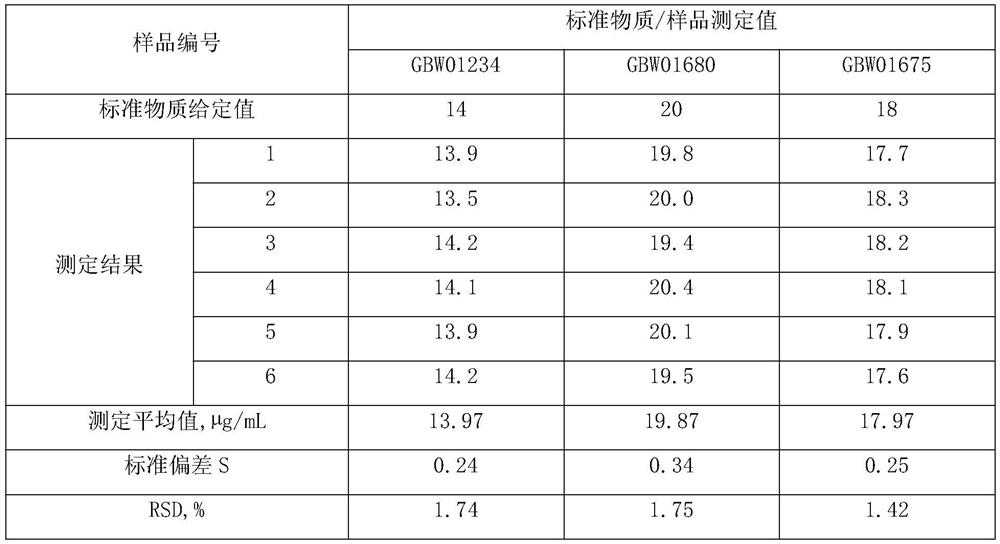

[0029] This embodiment relates to an ICP-OES method for determining zinc in electroslag steel, comprising the following steps: S1. sampling; S2. to be tested; S3. preparing a series of standard solutions; S4. forming a series of standard solutions; S5. establishing Working curve; S6. Calculating the content of relevant elements in the sample according to the working curve; S7. Determining the working parameters of the instrument; S8. Drawing the working curve; S9. Determining the content of zinc element in the sample solution.

[0030] Specific steps are as follows:

[0031] Using a sample weight of 0.2000 grams, taking into account the requirements of other element inspections, the mother liquor is dissolved to achieve multi-element determination. Control the appropriate sample volume to ensure the concentration of the elements to be determined and the total salinity of the sample. The sample volume has a great influence on the test results. If the uniformity of the sample is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com