Method for measuring calcium element in steel by ICP-OES

A calcium element and element technology, which is applied in the field of chemical substance analysis, can solve the problems of insufficient fast and convenient detection data, long time required for sample analysis, and inability to realize large-scale detection, etc., to achieve clear dissolution effect, reduce self-absorption effect, and save energy. The effect of human and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

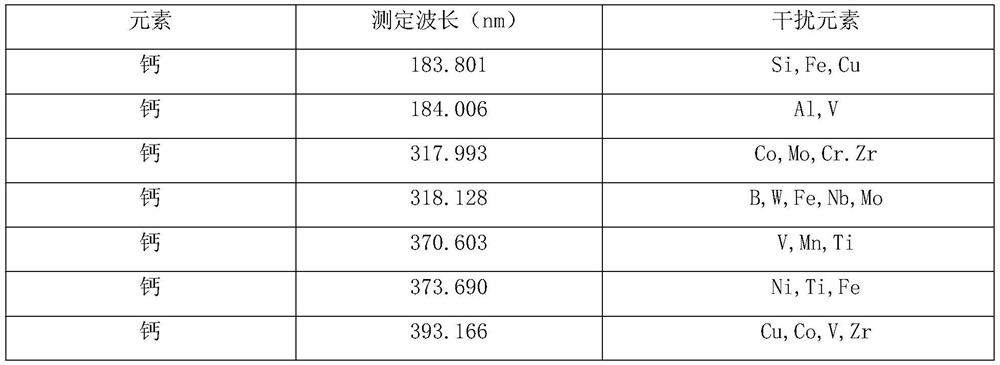

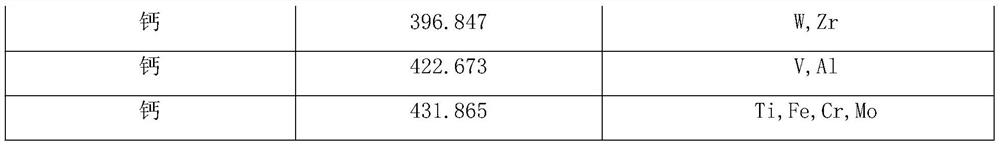

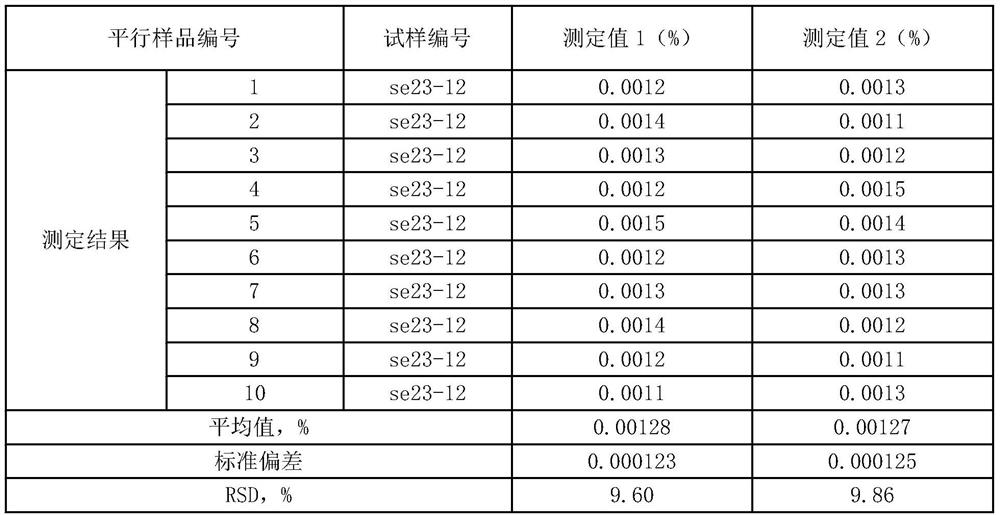

[0036] This embodiment relates to a method for ICP-OES determination of calcium in steel, said method comprising the following steps:

[0037]Step 1, sampling: at 1 / 2 of the sample radius, the drilling machine speed is controlled at 800r / min, and the test sample is drilled at a sampling depth of 2cm;

[0038] Step 2, weigh 0.2000g of the sample, accurate to 0.0001g, place the sample in a flat-bottomed volumetric flask, add 10ml of HCl+HNO 3 +H 2 O: (317+83+600), dissolve on the heating furnace, after the sample is completely decomposed, add 10ml H 2 SO 4 +H 3 PO 4 +H 2 O: (160+80+760), secondary dissolution, continue to dissolve, after the violent reaction stops, add 10mL of ultra-pure water along the wall of the bottle, continue heating process, large bubbles appear, there is no impurity in the bottom layer, after the dissolution is complete After the sample is dissolved, take it out and cool it to room temperature, dilute it with ultrapure water to a volume of 100mL to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com