Ceramic sagger

A technology of ceramics and saggers, applied in the field of ceramic saggers, can solve the problems of loading capacity, kiln output rate limitation, short service life, high energy consumption, etc., and achieve reduced kiln furniture loss, good thermal shock resistance, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention will be described in detail below, but the present invention can be implemented in a variety of different ways of claims;

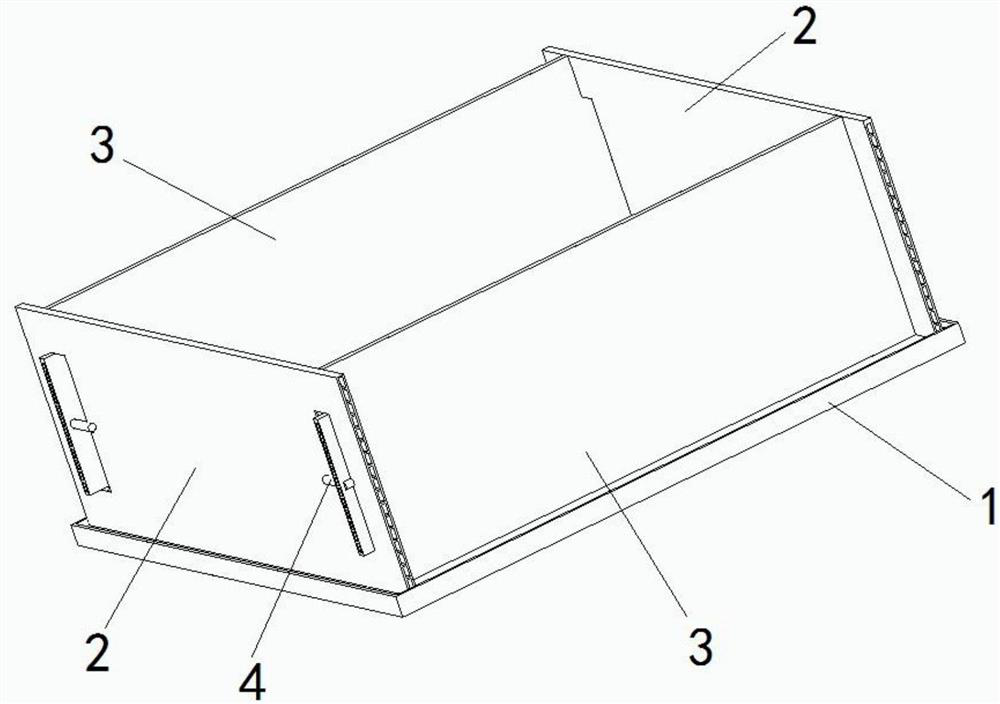

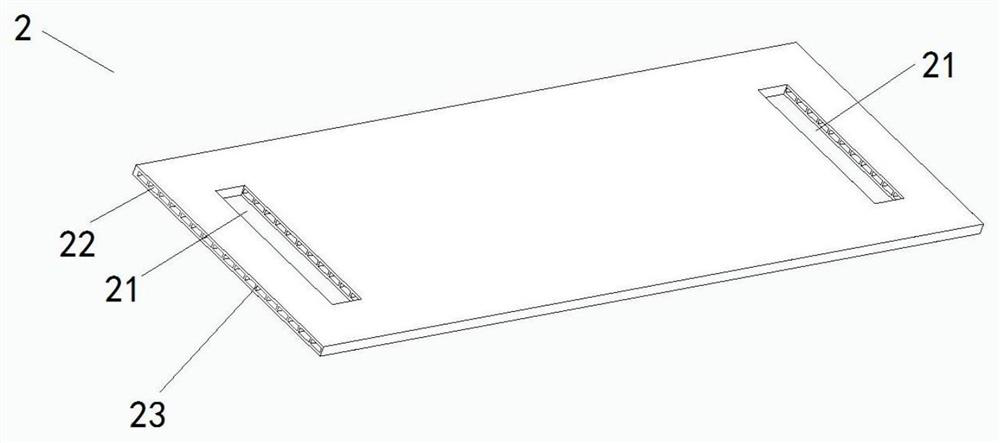

[0030] As a first embodiment of the present invention, a ceramic rat, such as figure 1 As shown, the bottom plate 1, two plates 2, two sheets 3, and 4 ceramic pins 4 are included.

[0031] The kiln corresponding to the martial arts of the program is a roller kiln, the net height of the kiln is 200mm, using a temperature of 1300 ° C, and the purpose is used for industrial alumina powder.

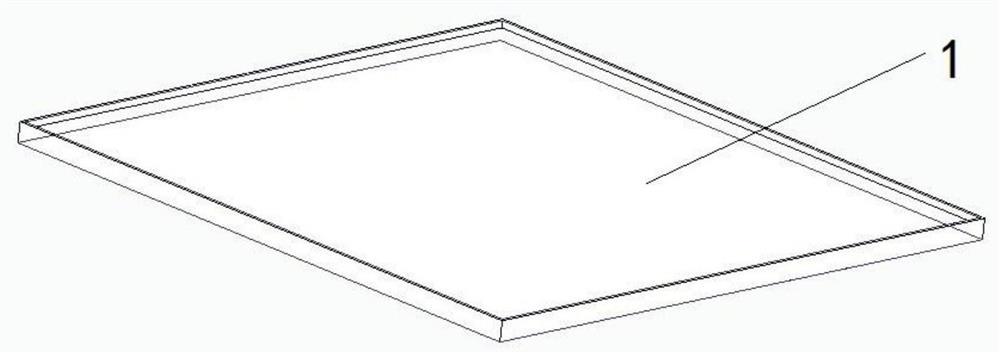

[0032] like figure 1 and figure 2 As shown, the bottom plate 1 is square shed, and the long width thick size is 450 mm * 450mm * 10 mm. The four sides of the bottom plate 1 are protruded such that the bottom of the mother plate 2 and the bottom of the sub-plate 3 engages the four sides of the bottom plate 1. The material of the bottom plate 1 can be used for cordierite, cordierite - mullite, mullite, mullite - corundum or silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com