Pre-embedded and prefabricated magnetic attraction end guiding type building crack repairing device and method based on magnetic force

An end-guiding, magnetic attraction technology, applied in the field of building crack repair, can solve the problems of poor fit of crack repair and long curing time, and achieve the effects of improving filling rate, complete and fast repair, and sufficient crack repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

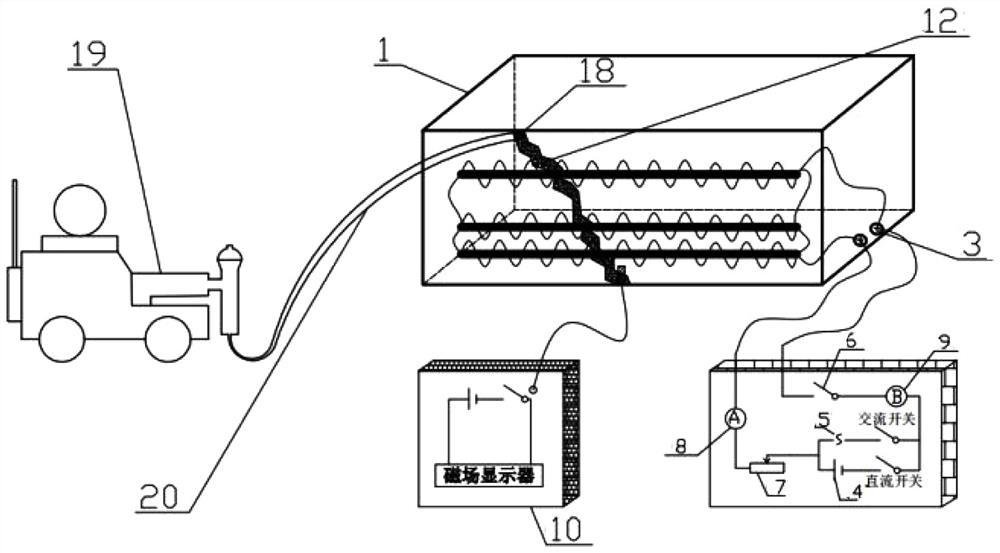

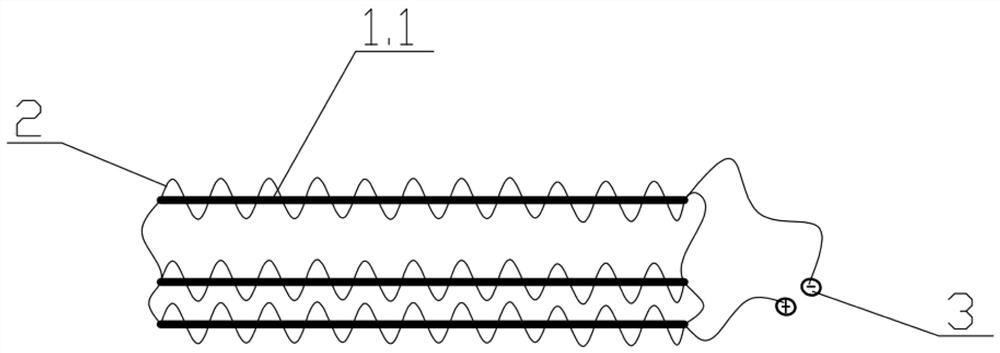

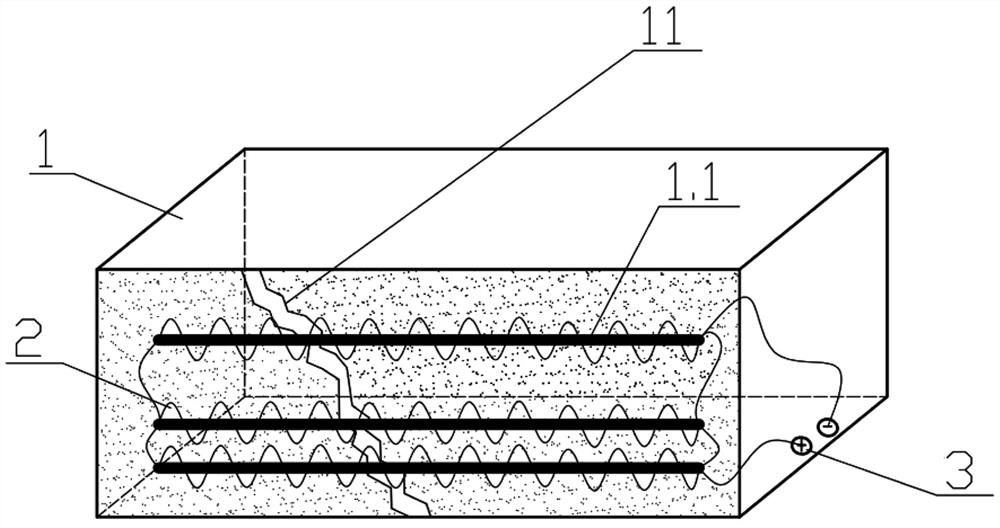

[0058] see Figure 1-4 A pre-embedded and prefabricated magnetic attraction-end-guided device for repairing cracks in buildings based on magnetic force, which includes a steel bar 1.1 pre-buried inside a reinforced concrete beam body 1, said steel bar 1.1 is wound with a tinned copper wire 2, said The tinned copper wire 2 passes through the reserved wire interface 3 preset on the reinforced concrete beam body 1, and is connected with the electromagnetic induction device for supplying electric current; There is an introduction hole 18, and the introduction hole 18 is connected with a high-pressure jet grouting machine 19 through a grouting pipe 20, and then injects magnetic mortar 12 into the crack. By adopting the above-mentioned device, it can be used for the repair of internal cracks of different types of buildings, and the filling of cracks can be realized by using the cooperation between the magnetic mortar 12 and a variety of different types of magnetic attraction ends, s...

Embodiment 2

[0070] The method for repairing cracks by using the magnetic-based pre-embedded and prefabricated magnetic attraction end-guided device for repairing cracks in buildings includes the following steps:

[0071] When the object to be repaired is a reinforced concrete beam body 1, the construction method of placing embedded electromagnetic coils is adopted, which specifically includes the following steps:

[0072] Step 1.1: According to the accumulation of experience in a large number of actual situations, before pouring the beam, use tinned copper wire 2 to wrap in parallel on the embedded steel bar 1.1, and control the number of winding turns according to the situation, and then pour the reinforced concrete beam body according to the normal process 1;

[0073] Step1.2: After the pouring of the reinforced concrete beam body 1 is completed, the reserved wire interface 3 is set outside for use, and the oxidation prevention treatment of the reserved wires should be done well, and at...

Embodiment 3

[0080] When the object to be repaired is the 15 leaky parts on the bathroom floor, the construction method of placing the pre-embedded permanent magnet net is adopted, which specifically includes the following steps:

[0081] Step2.1: During the ground construction process of the toilet, when making the ground leveling layer, pre-embed the permanent magnet net 17;

[0082] Step2.2: Due to the large amount of water infiltration in the bathroom, and the waterproofness of the waterproof layer is limited, under the effect of water intrusion for a long time, the properties of the concrete will be destroyed, and cracks will appear on the bathroom floor;

[0083] Step2.3: Use a small drill bit drill to drill the elongated lead hole 18 at the position where the crack occurs to inject the magnetic mortar 12;

[0084] Step2.4: Prepare the required magnetic mortar, inject the magnetic mortar along the slender lead hole with a high-pressure jet grouting machine, and under the magnetic att...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com