Polyurethane/cotton cellulose composite aerogel insole and preparation method thereof

A technology of compounding aerogel and cotton cellulose, which is applied in insoles, footwear, applications, etc., to achieve the effects of easy promotion, expansion of application fields, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

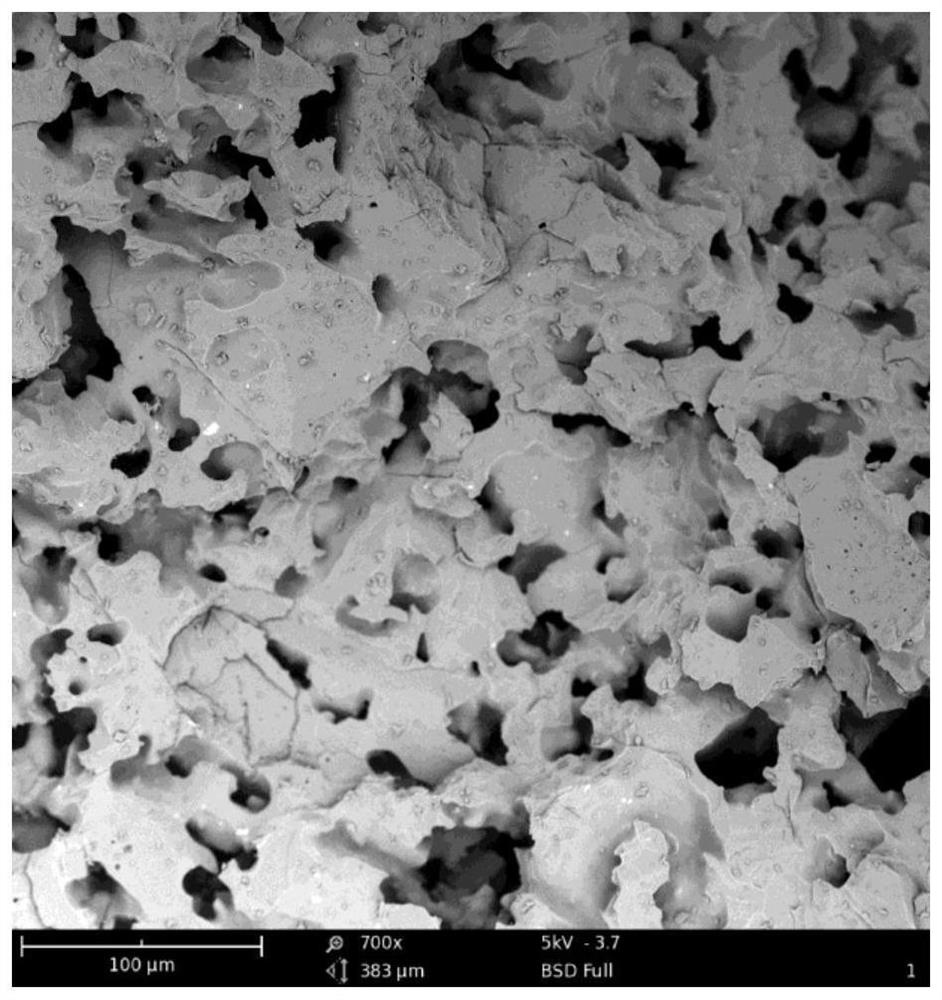

Image

Examples

Embodiment 1

[0026] In this embodiment, a polyurethane / cotton cellulose composite airgel insole is prepared by the following method, including the following steps:

[0027] (1) Preparation of water-based polyurethane: Add 0.75 mol of polyethylene glycol with a molecular weight of 2000 into a three-necked flask, vacuumize at 93°C for 1.5h to remove moisture; cool to 70°C, add 0.225mol of toluene diisocyanate for reaction , the reaction time is 1.5h; refer to the HG / T2409-1992 method to measure the content of NCO, add 0.02mol dimethylolpropionic acid to carry out the chain extension reaction for 0.75h; cool down to 5°C, add 3% sodium bisulfite dissolved in A mixed solution of 80mL isopropanol and 200mL water was stirred at high speed for 0.75h; after the reaction, the pH value was adjusted to 3.5 to obtain a water-based polyurethane emulsion;

[0028] (2) Preparation of cotton cellulose solution: Dissolve 20g of waste cotton fabric in 150mL of sodium hydroxide-urea-water mixed solution at -7...

Embodiment 2

[0032] In this embodiment, a polyurethane / cotton cellulose composite airgel insole is prepared by the following method, including the following steps:

[0033] (1) Preparation of water-based polyurethane: Add 0.5 mol of polyethylene glycol with a molecular weight of 2000 into a three-necked flask, vacuumize at 90°C for 1 hour to remove moisture; cool to 60°C, add 0.15mol of toluene diisocyanate for reaction, The reaction time is 1h; refer to the HG / T2409-1992 method to determine the content of NCO, add 0.01mol dimethylolpropionic acid to carry out the chain extension reaction for 0.5h; cool down to 0°C, add 80mL isocyanate dissolved in 1% sodium bisulfite The mixed solution of propanol and 160mL water was stirred at a high speed for 0.5h; after the reaction was completed, the pH value was adjusted to 3 to obtain a water-based polyurethane emulsion;

[0034] (2) Preparation of cotton cellulose solution: Dissolve 20g of waste cotton fabric in 150mL of sodium hydroxide-urea-water...

Embodiment 3

[0038] In this embodiment, a polyurethane / cotton cellulose composite airgel insole is prepared by the following method, including the following steps:

[0039] (1) Preparation of water-based polyurethane: Add 1 mol of polyethylene glycol with a molecular weight of 2000 into a three-necked flask, vacuumize at 95°C for 2 hours to remove moisture; cool to 80°C, add 0.3mol of toluene diisocyanate to react, react The time is 2 hours; refer to the HG / T2409-1992 method to measure the content of NCO, add 0.03mol dimethylolpropionic acid for chain extension reaction for 1 hour; cool down to 8°C, add 150mL of isopropanol dissolved in 5% sodium bisulfite and The mixed solution of 450mL water was stirred at high speed for 1 hour; after the reaction was completed, the pH value was adjusted to 4 to obtain a water-based polyurethane emulsion;

[0040] (2) Preparation of cotton cellulose solution: Dissolve 20g of waste cotton fabric in 150mL of sodium hydroxide-urea-water mixed solution at -1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com