Polycarboxylate superplasticizer based on 6C polyether macromonomer and preparation method thereof

A technology of polyether macromonomer and polycarboxylic acid, which is applied in the field of polycarboxylate water reducer and its preparation, can solve the problems of high cost, insufficient performance, and long time consumption, and achieve improved conversion rate, good adaptability, and reduced cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

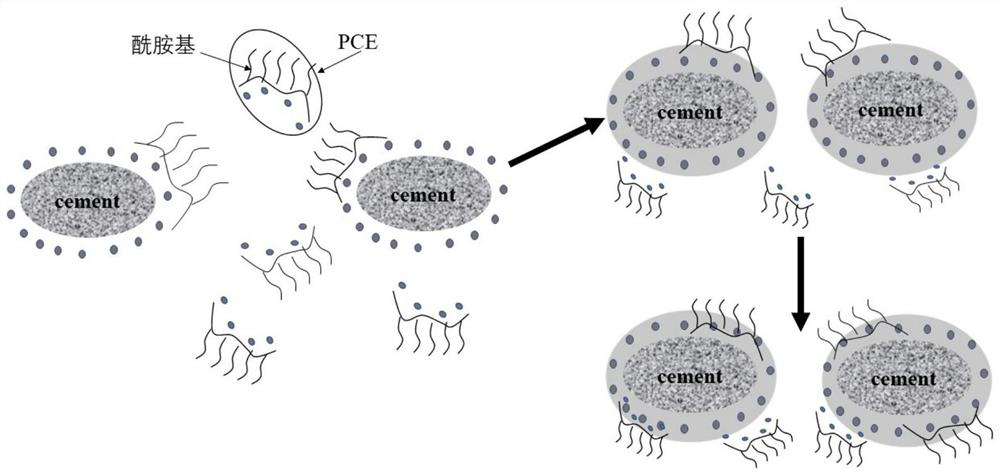

[0050] The second, the present invention provides a kind of preparation method of the polycarboxylate water-reducer based on 6C polyether macromonomer, comprises the steps:

[0051] Dissolve diethylene glycol monovinyl ether in water, add iron oxide for mixing, then add acrylic acid monomer solution and chain transfer agent solution dropwise at the same time, and keep warm during the dropping process to obtain polycarboxylate water reducer.

[0052] The specific preparation method is as follows. Add diethylene glycol monovinyl ether macromonomer and water into a reactor with a thermometer, gradually lower the temperature and stir until dissolved. When the base ether macromonomer is completely dissolved, add iron oxide, mix and stir for 20 to 30 minutes, add the oxidant after mixing evenly, mix and stir for 5 to 10 minutes, and at the same time dropwise add the acrylic monomer solution and the chain transfer agent solution at a uniform speed, drop During the process, the temper...

Embodiment 1

[0061] The preparation method of the polycarboxylate water reducer based on 6C polyether macromonomer, the specific steps are:

[0062] (1) Acrylic acid monomer solution (acrylic acid 3.66g, acrylamide 0.12g, allyl sodium sulfonate 0.07g and distilled water 14.38g) and chain transfer agent solution (ascorbic acid 0.024g, thioglycolic acid 0.206g and distilled water were prepared respectively) 18.8792g) for use;

[0063] (2) Add 36.02g of macromonomer (EPEG) and 15.31g of distilled water into a three-necked flask equipped with a thermometer. At room temperature, gradually control the temperature and stir to dissolve. When the temperature is controlled to 10°C and the macromonomer is completely dissolved, Add 0.005g of ferric oxide and 3g of water, mix and stir for 20min, then add 0.25g of hydrogen peroxide and 0.5g of water, after mixing evenly, add acrylic acid monomer solution dropwise at a constant speed (40min) and chain The transfer agent solution (70min dripping), the ho...

Embodiment 2

[0065] The preparation method of the polycarboxylate water reducer based on 6C polyether macromonomer, the specific steps are:

[0066] (1) Acrylic acid monomer solution (acrylic acid 3.56g, acrylamide 0.16g, allyl sodium sulfonate 0.14g and distilled water 14.38g) and chain transfer agent solution (ascorbic acid 0.042g, thioglycolic acid 0.1066g and distilled water were prepared respectively) 18.89g) for use;

[0067] (2) Add 30.0211g of macromonomer (EPEG) and 15.95g of distilled water into a three-necked flask equipped with a thermometer. At room temperature, gradually control the temperature and stir to dissolve. When the temperature is controlled to 15°C and the macromonomer is completely dissolved, Add 0.015g of ferric oxide and 2g of water, mix and stir for 20min, then add 0.25g of hydrogen peroxide and 0.5g of water, after mixing evenly, add the acrylic acid monomer solution (dropping in 42min) and chain The transfer agent solution (dropped in 72 minutes), the holding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com