A light-burning solid waste 3D printing ventilation and airtight material and its preparation method

A 3D printing and airtight technology, which is applied in the field of light-burning solid waste 3D printing ventilation and airtight materials and its preparation, can solve problems that affect mine safety production, high construction costs, and brittle damage, and achieve resource utilization and excellent accumulation Performance and strength properties, the effect of avoiding brittle failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The present invention also provides a method for preparing light-burned solid waste 3D printing ventilation and sealing materials. The preparation method is prepared by using the component raw materials contained in the light-burning solid waste 3D printing ventilation and sealing materials. The preparation method includes the following steps :

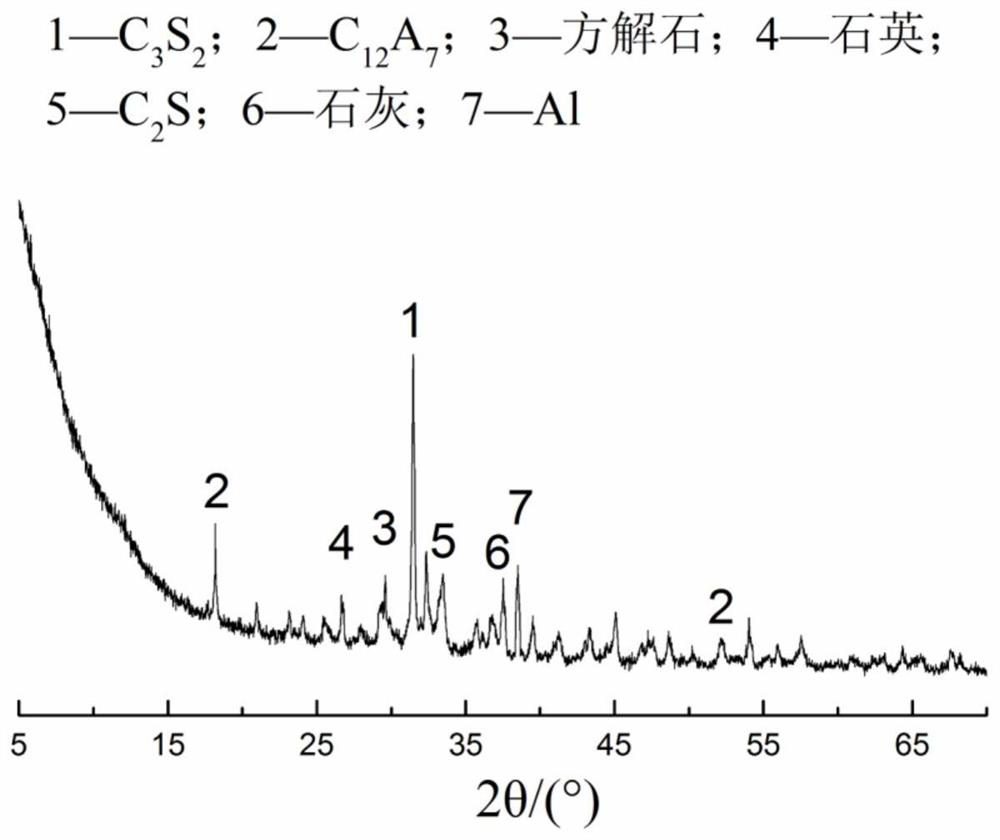

[0052] Step S1, pretreat the bottom ash of medical waste incineration, fly ash of domestic waste incineration and phosphogypsum, and then weigh the pretreated bottom ash of medical waste incineration, fly ash of domestic waste incineration and phosphogypsum according to the proportion and mix them evenly, Then it is calcined at a high temperature in a furnace, cooled at room temperature and ground to obtain an active admixture.

[0053] In a specific embodiment of the present invention, the pretreatment of medical waste incineration bottom ash, domestic waste incineration fly ash and phosphogypsum in step S1 is specifically at ...

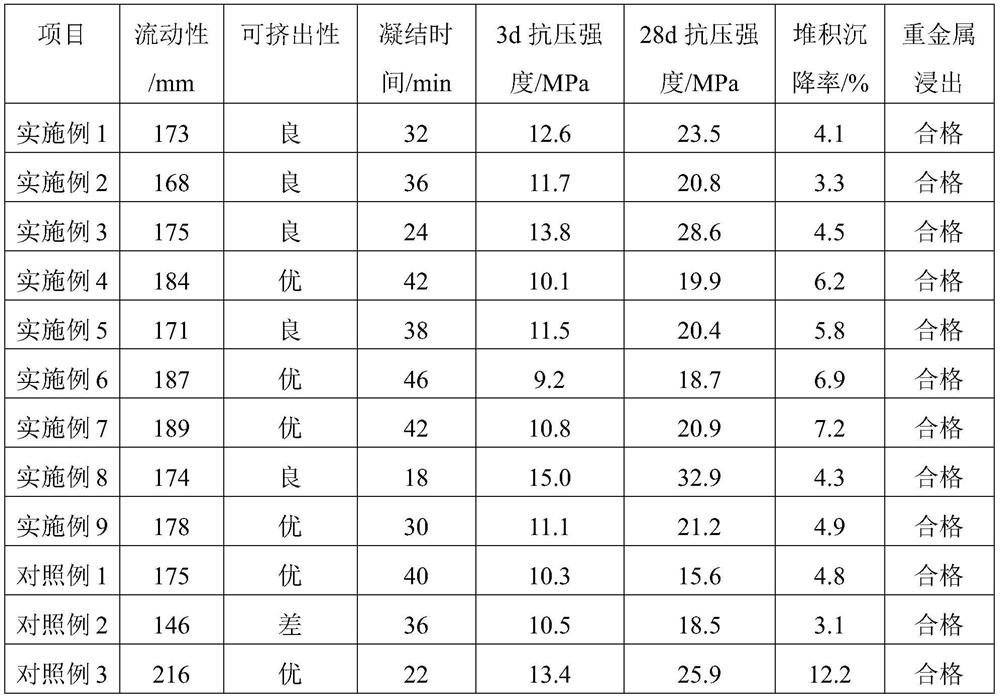

Embodiment 1

[0073] This embodiment provides a light-burning solid waste 3D printing ventilation and sealing material, which includes the following raw materials in parts by weight: 25 parts of medical waste incineration bottom ash, 8 parts of phosphogypsum, Portland cement 40 parts of clinker, 6.5 parts of domestic waste incineration fly ash, 120 parts of spontaneous combustion coal gangue, 4.5 parts of carbide slag, 0.3 parts of aluminum sulfate, 0.2 parts of sodium carbonate, 0.5 parts of sodium methyl silicate, 4.5 parts of acrylic acid emulsion, carboxymethyl Base cellulose sodium 0.1 part, water 34 parts.

[0074] In this embodiment, the preparation method of light-burned solid waste 3D printing ventilation and airtight materials includes the following steps:

[0075] Step S1. Dry the bottom ash of medical waste incineration, fly ash of domestic waste incineration and phosphogypsum at 110°C to constant weight, screen out the metal impurities in the bottom ash of medical waste inciner...

Embodiment 2

[0084] This embodiment provides a light-burning solid waste 3D printing ventilation and sealing material. The ventilation and sealing material includes the following raw materials in parts by weight: 25 parts of medical waste incineration bottom ash, 5 parts of phosphogypsum, Portland cement 30 parts of clinker, 8 parts of domestic waste incineration fly ash, 60 parts of spontaneous combustion coal gangue, 3 parts of carbide slag, 0.2 parts of aluminum sulfate, 0.2 parts of sodium carbonate, 0.5 parts of sodium methyl silicate, 4 parts of acrylic emulsion, carboxymethyl Base cellulose sodium 0.1 part, water 28 parts.

[0085] The difference between the preparation method of light-burned solid waste 3D printing ventilation and airtight materials in this example and the preparation method in Example 1 is that the amount of raw materials in this example is according to the proportion of the above components in this example, and the calcination in step S1 The temperature is 850° C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com