Preparation method of antibacterial mildew-proof filter cotton

An antibacterial, mildew-proof, and filter cotton technology, which is applied in the field of filter materials, can solve the problems of filter cotton antibacterial performance decline, impact, and easy loss of antibacterial agents, and achieve good sound-absorbing effects, rich functions, and improved filter performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

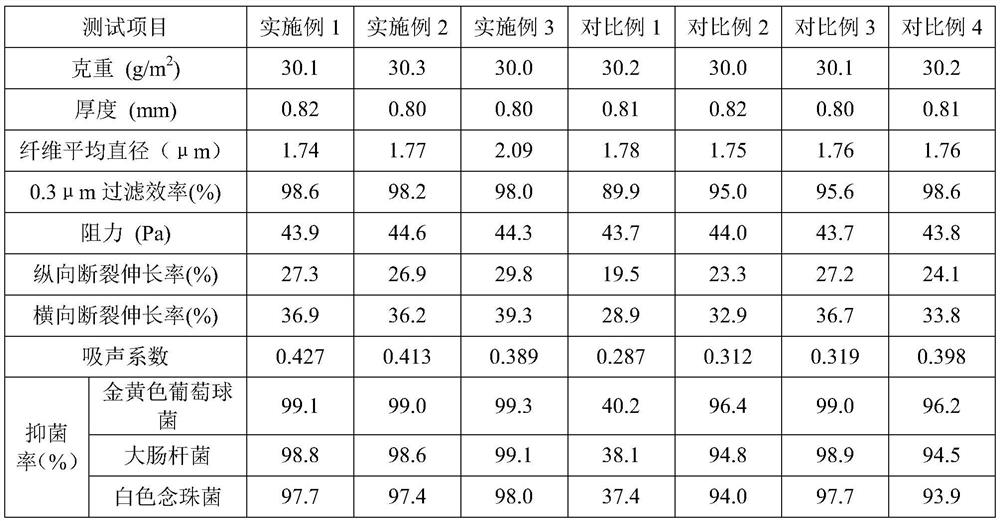

Examples

Embodiment 1

[0032] A preparation method for antibacterial and mildew-proof filter cotton, comprising the steps of:

[0033] (1) Preparation of azide-modified nano-titanium dioxide:

[0034] A) Add ammonia water and γ-aminopropyltriethoxysilane with a mass concentration of 25% into water, stir evenly and add nano-titanium dioxide, ammonia water, γ-aminopropyltriethoxysilane, water and nano-titanium dioxide The ratio is 5mL: 8mL: 900mL: 8g, stirred and reacted at 80°C for 8h, filtered and cleaned to obtain amino-modified nano-titanium dioxide;

[0035] B) Dissolve p-azidobenzoic acid in dichloromethane, add N,N-dimethylformamide and oxalyl chloride, stir for 4 hours, then add amino-modified nano-titanium dioxide, p-azidobenzoic acid and dichloromethane , N,N-dimethylformamide, oxalyl chloride, and amino-modified nano-titanium dioxide are added at a ratio of 14g:250mL:12mL:3.5mL:5g, and the stirring reaction is continued for 12h, and the product is washed and dried to obtain the analyte Ni...

Embodiment 2

[0041] A preparation method for antibacterial and mildew-proof filter cotton, comprising the steps of:

[0042] (1) Preparation of azide-modified nano-titanium dioxide:

[0043] A) Add ammonia water and γ-aminopropyltriethoxysilane with a mass concentration of 28% into water, stir evenly and add nano-titanium dioxide, ammonia water, γ-aminopropyltriethoxysilane, water and nano-titanium dioxide The ratio is 4mL: 7mL: 800mL: 7g, stirred and reacted at 70°C for 9h, filtered and cleaned to obtain amino-modified nano-titanium dioxide;

[0044] B) Dissolve p-azidobenzoic acid in dichloromethane, add N,N-dimethylformamide and oxalyl chloride, stir and react for 3 hours, then add amino-modified nano-titanium dioxide, p-azidobenzoic acid and dichloromethane , N,N-dimethylformamide, oxalyl chloride, and amino-modified nano-titanium dioxide are added in a ratio of 13g:200mL:10mL:3mL:5g, and the stirring reaction is continued for 18h, and the product is washed and dried to obtain the azide...

Embodiment 3

[0050] A preparation method for antibacterial and mildew-proof filter cotton, comprising the steps of:

[0051] (1) Preparation of azide-modified nano-titanium dioxide:

[0052] A) Add ammonia water and γ-aminopropyltriethoxysilane with a mass concentration of 25% into water, stir evenly and add nano-titanium dioxide, ammonia water, γ-aminopropyltriethoxysilane, water and nano-titanium dioxide The ratio is 6mL: 9mL: 1000mL: 9g, stirred and reacted at 90°C for 7h, filtered and washed to obtain amino-modified nano-titanium dioxide; B) Dissolve p-azidobenzoic acid in dichloromethane, add N,N-di Methylformamide and oxalyl chloride, after stirring for 5 hours, add amino-modified nano-titanium dioxide, p-azidobenzoic acid, dichloromethane, N,N-dimethylformamide, oxalyl chloride, amino-modified nano-titanium dioxide The addition ratio is 15g: 300mL: 15mL: 4mL: 5g, and the stirring reaction is continued for 10h, and the product is washed and dried to obtain the azide-modified nano-ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com