Preparation method of novel Fe<1-x>TM<x>S single crystal material

A technology of fe1-xtmxs and fe1.6-xtmxs2, which is applied in the field of preparation of single crystal materials, can solve the problems of preparation failure, violent reaction, and difficulty in controlling the content of transition metal elements, so as to improve quality and stability, and make the preparation process safe simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

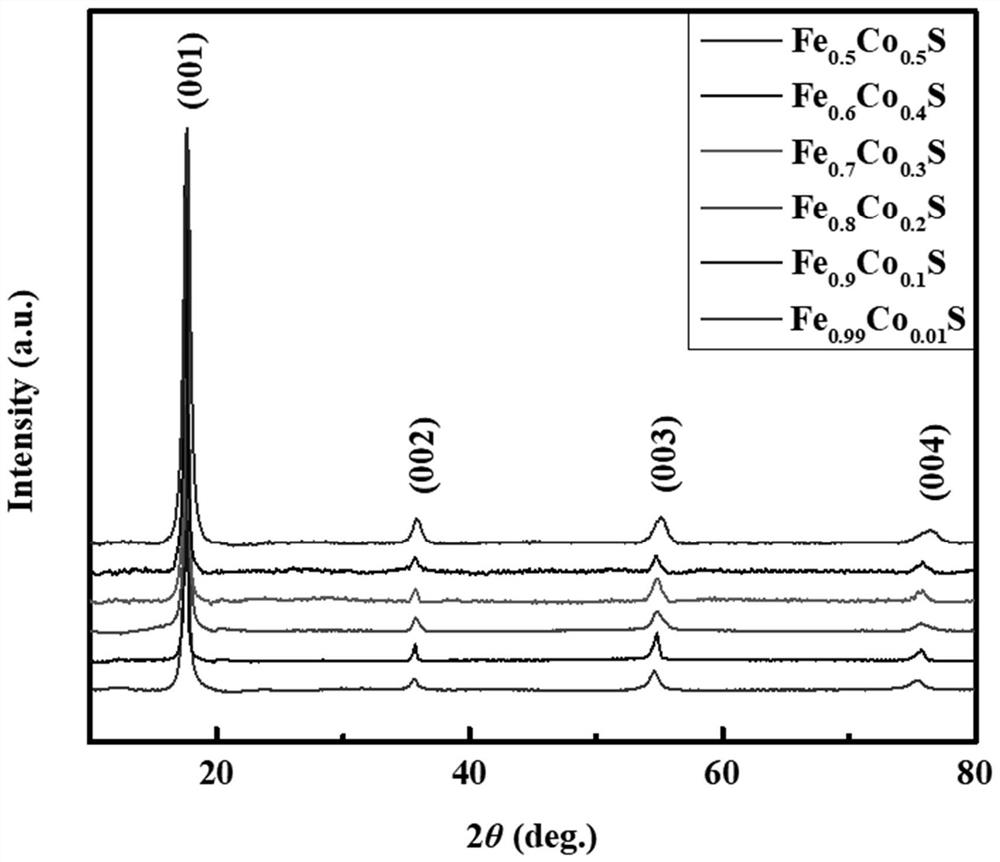

Image

Examples

Embodiment 1

[0025] a. Preparation FE 1.6-x CO x S 2 Polycrystalline: Put the iron powder, cobalt powder and sulfur powder according to Fe 1.6-x CO x S 2 The atomic ratio was weighed, and the raw material was grinded in a mortar in a mortar for more than 30 minutes, and then the ground sample was sealed into a vacuum quartz, and then the quartz pipe was placed in a box furnace to sinter at 500 ° C for 24 hours. After cooling to room temperature to get Fe 1.6-x CO x S 2 Polycrystalline;

[0026] b. Preparation k 0.8 FE 1.6-x CO x S 2 Single crystal: 1.6G Fe 1.6-x CO x S 2 Polycrystalline and 0.328 g of the potassium were sealed into vacuum quartzers, followed by sintering the quartz pipe in a box furnace at 1000 ° C for 24 hours and slowly cooled to 700 ° C at a rate of 5 ° C / h, and dissociated K 0.8 FE 1.6-x CO x S 2 Single crystal;

[0027] c. Formulated a mixed solution under an inert atmosphere, adding 0.12 g of sodium hydroxide and 0.23 g of thiourea to 10 ml of water to give a mixed sol...

Embodiment 2

[0032] a. Preparation FE 1.6-x Ni x S 2 Polycrystalline: Push iron powder, nickel powder and sulfur powder according to Fe 1.6-x Ni x S 2 The atomic ratio was weighed, and the raw material was grinded in a mortar for more than 30 minutes, and then the grinding sample was sealed into a vacuum quartz, then put the quartz pipe in the box furnace was sintered at 450 ° C for 24 hours. After cooling to room temperature to get Fe 1.6-x Ni x S 2 Polycrystalline;

[0033] b. Preparation k 0.8 FE 1.6-x Ni x S 2 Single crystal: 0.16g Fe 1.6-x Ni x S 2 Polycrystalline and 0.328 g of a single potassium enclosed in vacuum quartzers, then put the quartz pipe in a box furnace at 1020 ° C for 24 hours and slowly cooled to 700 ° C at a rate of 5 ° C / h, and dissociated K 0.8 FE 1.6-x Ni x S 2 Single crystal;

[0034]c. Formulated a mixed solution under an inert atmosphere, adding 0.12 g of sodium hydroxide and 0.23 g of thiourea to 10 ml of water to give a mixed solution.

[0035] d. Press K again...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com