Treatment method of ethanolamine waste liquid

A treatment method and ethanolamine technology, applied in combustion methods, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of increasing the total amount of sewage, toxic and harmful gases, waste of water resources, etc., and reduce energy consumption and water quality. The effect of index reduction and treatment method cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

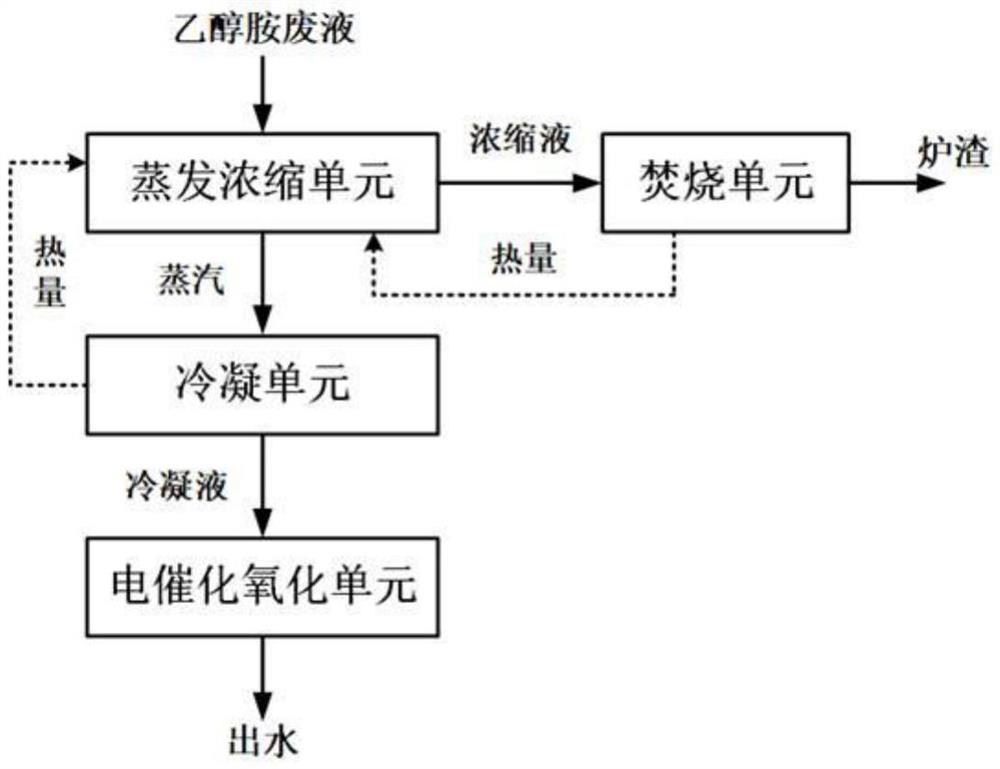

[0031] A treatment method for ethanolamine waste liquid, comprising the following steps:

[0032] Step 1: Evaporate and concentrate the ethanolamine waste liquid through the evaporative concentration unit, control the heating temperature of the evaporative concentration to 150°C, and evaporate and concentrate until the volume of the organic residue concentrated liquid accounts for 20% of the volume of the ethanolamine waste liquid, then discharge the organic residual concentrated liquid into The incineration unit performs incineration treatment, and the steam generated by evaporation and concentration is passed into the condensation unit for condensation treatment. During the distillation process, the temperature of the steam distillation outlet is always controlled to not exceed 100°C.

[0033] Step 2: The steam generated by the evaporation and concentration unit is passed into the condensation unit, and the condensation adopts the method of indirect heat exchange, and the exc...

Embodiment 2

[0037] A treatment method for ethanolamine waste liquid, comprising the following steps:

[0038] Step 1: Evaporate and concentrate the ethanolamine waste liquid through the evaporative concentration unit, control the heating temperature of the evaporative concentration to 140°C, and evaporate and concentrate until the volume of the organic residue concentrated liquid accounts for 25% of the volume of the ethanolamine waste liquid, then discharge the organic residual concentrated liquid into The incineration unit performs incineration treatment, and the steam generated by evaporation and concentration is passed into the condensation unit for condensation treatment. During the distillation process, the temperature of the steam distillation outlet is always controlled to not exceed 100°C.

[0039] Step 2: The steam generated by the evaporation and concentration unit is passed into the condensation unit, and the condensation adopts the method of indirect heat exchange, and the exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com