Cultivation material for Nanhua volvariella volvacea, composting method of cultivation material and cultivation method of Nanhua volvariella volvacea

A cultivation method and cultivation material technology are applied to the cultivation of Nanhua straw mushrooms, the cultivation materials of Nanhua straw mushrooms and the fields of their composting, which can solve the problems of increasing the cost of planting Nanhua straw mushrooms, rising prices and the like, and achieve normal growth, reduce material temperature, The effect of increasing water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Based on the above technical solution, this embodiment 1 provides a Nanhua straw mushroom cultivation material, which includes the following components: 75% to 82% of mushroom residue, 3% to 5% quicklime, and 15% to 20% crushed rice straw.

[0032] Wherein, the various components of the Nanhua straw mushroom cultivation material can be the components shown in the following table:

[0033] components True Jiji Mushroom Residue quicklime broken straw Matching ratio 1 75% 5% 20% Matching 2 78% 3% 19% Matching ratio 3 77% 5% 18% Matching ratio 4 80% 3% 17% Matching ratio 5 79% 5% 16% Proportion 6 82% 3% 15%

[0034] Among them, the shredded straw can be made by pulverizing the purchased dry straw through a pulverizer, which is cheap and does not require long-distance transportation. Wherein, the grain size of the broken rice straw is between 10cm and 15cm in length.

[0035] Compared with the traditional t...

Embodiment 2

[0038] A kind of composting method of Nanhua straw mushroom cultivation material is provided in the present embodiment 2, comprises the steps:

[0039] Add 3% to 5% quicklime to the mushroom slag of jiji mushrooms, build a heap and ferment for 7 to 8 days, turn the heap evenly every two days, add 15% to 20% crushed straw after fermentation for 7 days, and heap and retting for 3 days to obtain Finished Nanhua Straw Mushroom Cultivation Material.

[0040] Wherein, by adding quicklime, it is possible to adjust the pH value of the fungus slag of Shijiji mushroom to meet the needs of cultivation.

[0041] Among them, the purpose of fermenting the cultivation material including rice straw for 7 to 8 days and composting for 3 days is to fully ferment the fungus residue. At the same time, the straw fermentation time is short and will not be retting, which not only makes full use of the organic matter in the straw, but also makes the straw It can better play the role of increasing air...

Embodiment 3

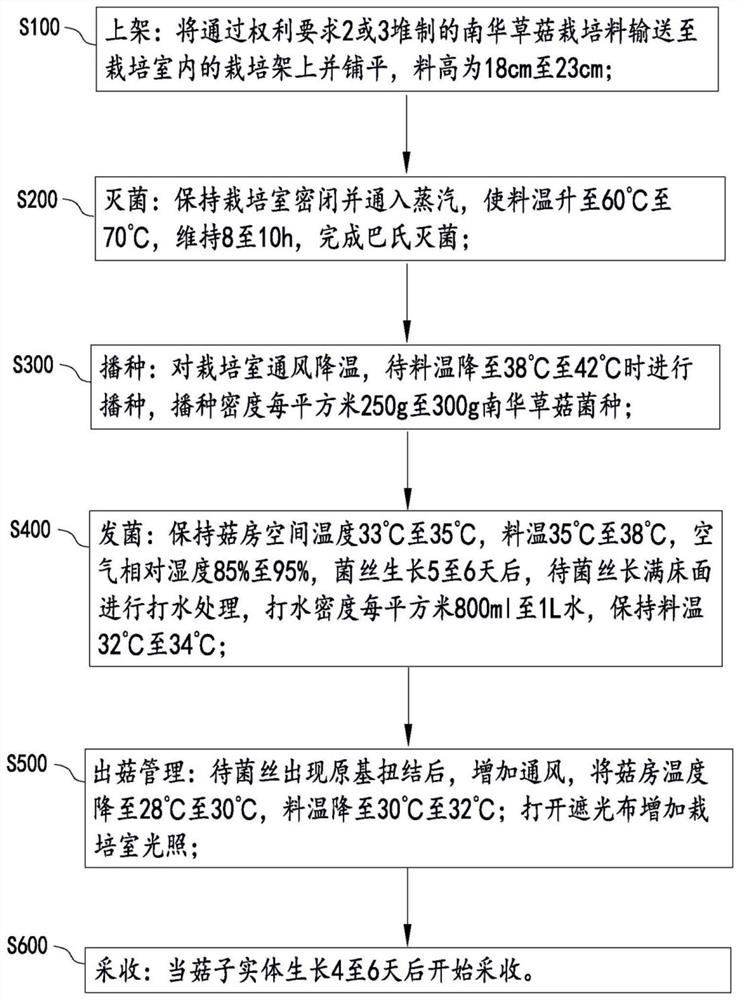

[0046] Present embodiment 3 provides a kind of Nanhua straw mushroom cultivation method using above-mentioned Nanhua straw mushroom cultivation material, such as figure 1 shown, including the following steps:

[0047] S100, put on the shelf: transfer the composted cultivation material to the cultivation shelf in the cultivation room and lay it flat, the height of the material is 18cm to 23cm.

[0048] S200. Sterilization: Keep the cultivation room airtight and pass steam to raise the temperature of the material to 60°C to 70°C and maintain it for 8 to 10 hours to complete the pasteurization.

[0049] S300, sowing: ventilating and cooling the cultivation room, and sowing when the material temperature drops to 38°C to 42°C, the seeding density is 250g to 300g of bacteria per square meter.

[0050] S400, Bacteria: keep the space temperature of the mushroom house at 33°C to 35°C, the temperature of the material at 35°C to 38°C, and the relative humidity of the air at 85% to 95%. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com