Preparation method of high-safety long-life ceramic diaphragm

A ceramic diaphragm, high-safety technology, applied in the field of electrochemistry, can solve problems such as applications that cannot meet safety requirements, increased internal resistance, membrane rupture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

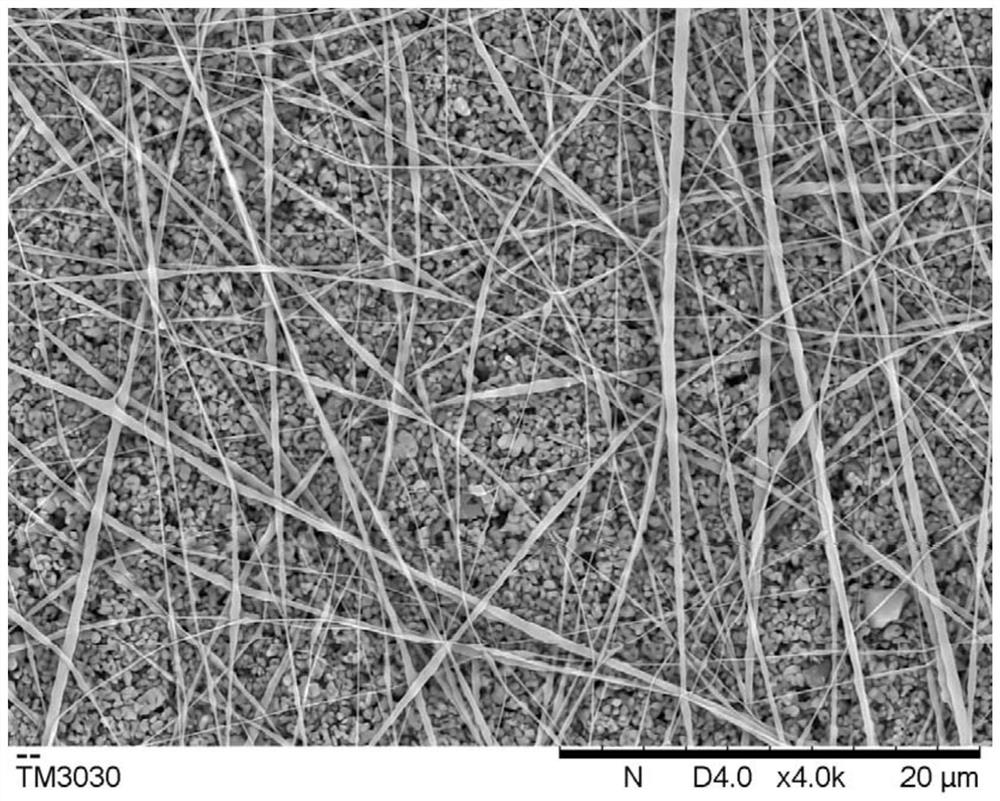

[0055] Fully mix silica spherical powder with a particle size of about 300nm, binder (styrene-butadiene rubber (SBR), carboxymethyl cellulose (CMC)) to make a slurry, and its mass ratio is: silica / SBR / CMC=0.95g / 0.03g / 0.02g, the solvent is a water / ethanol mixture with a volume ratio of 1:1, and the mass ratio of liquid to solid is 90:10.

[0056] The prepared slurry was evenly coated on both sides of a commercial polyethylene (PE) separator with an automatic coating machine, and after drying at room temperature, it was dried in vacuum at 50° C. for 10 hours to obtain a silica ceramic coated separator.

[0057] Use a water / ethanol mixture with a volume ratio of 1:1 as a solvent to prepare a water-soluble phenolic resin solution with a mass fraction of 10 g / L and a molecular weight of 3000.

[0058] Pour the previously prepared silica ceramic-coated diaphragm into the above-mentioned prepared water-soluble phenolic resin solution, place the system on a shaker, shake at a frequen...

Embodiment 2

[0068] The difference between embodiment 2 and embodiment 1 is:

[0069] Fully mix alumina powder with a particle size of 300nm and a binder (polyvinylidene fluoride-hexafluoropropylene (PVDF-HFP)) to make a slurry, the mass ratio of which is: alumina / PVDF-HFP=0.9g / 0.1g, the solvent is NMP / acetone mixed solution with a volume ratio of 1:1, and the mass ratio of liquid to solid is 90:10.

[0070] The prepared slurry was evenly coated on one side of a commercial polyethylene (PE) separator with an automatic coating machine, and after drying at room temperature, it was dried in vacuum at 50° C. for 10 hours to obtain an alumina ceramic coated separator.

[0071] Use a water / ethanol mixture with a volume ratio of 1:1 as a solvent to prepare a water-soluble phenolic resin solution with a mass fraction of 15g / L and a molecular weight of 3000.

[0072] The above prepared water-soluble phenolic resin solution was scratch-coated on the previously prepared alumina ceramic coated diaph...

Embodiment 3

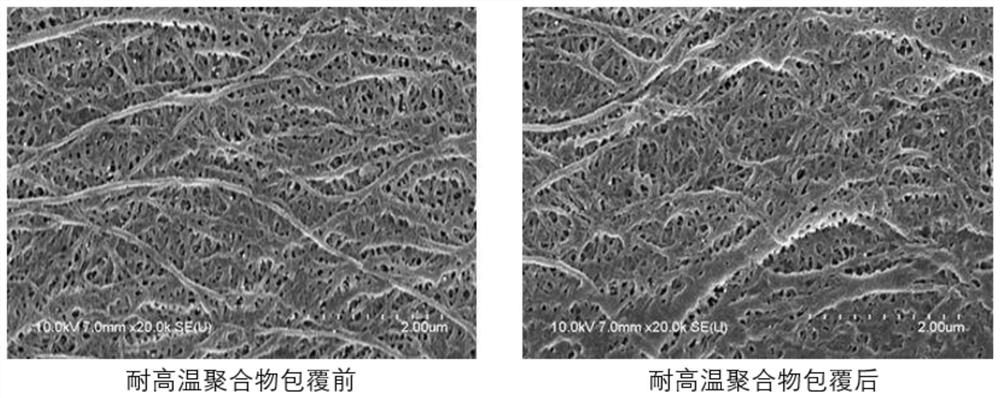

[0076] 2gPMMA was dissolved in 8gDMF solvent, stirred on a magnetic stirrer for 12h, and ultrasonicated for 10min to remove air bubbles. Take 1mL of the PVDF solution into a 3mL syringe, take the 20cm×80cm ceramic diaphragm base material of the three-dimensional composite structure in Example 1, put it on the round roller collector and fix it with adhesive tape, with the ceramic layer facing outwards, and adjust the electrospinning speed. The parameters are: positive voltage is 10kV; negative voltage is -2kV; injector advance speed is 0.02mm / min; collector rotation speed is 50rpm; distance between injector and collector is 25cm; temperature is 30°C; humidity is 50% ; After 60min, a PMMA polymer layer with a thickness of about 1 μm was obtained, which was placed in a vacuum drying oven at 60°C for 24h, and then fixed on the round roller collector again, with the ceramic layer facing inward, and 1mL of Put the PMMA solution into a 3mL syringe, and use the same electrospinning pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com