Negative electrode, and preparation method and application thereof

A technology of negative electrode and negative electrode activity, applied in the direction of negative electrode, electrode manufacturing, battery electrode, etc., can solve the problems of complicated operation, reduced effectiveness, first charge and discharge efficiency and discharge capacity need to be further improved, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

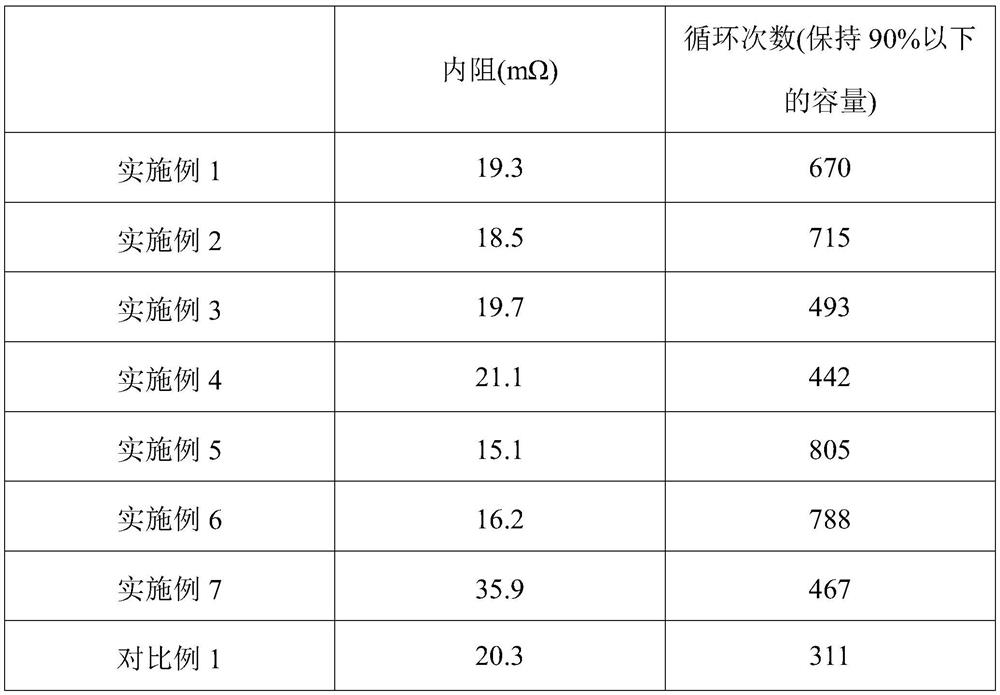

Embodiment 1

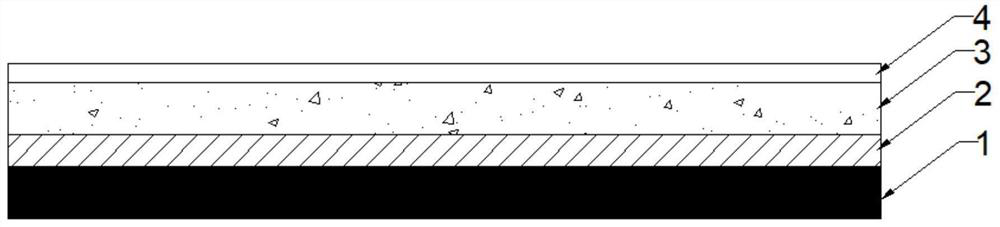

[0068] This embodiment provides a negative electrode, which includes a current collector 1 , a negative electrode active material layer 2 , a slow-release layer 3 and an active lithium layer 4 which are sequentially stacked, and the thickness of the slow-release layer is 10 μm.

[0069] The preparation method of the negative electrode is as follows:

[0070] (1) Weigh lithium lanthanum zirconium oxide (LLZO), polyethylene oxide (PEO) and conductive carbon black (mass fraction of lithium lanthanum zirconium oxygen is 67wt%, polyethylene oxide is 4:1:1) 16.5wt%, conductive carbon black is 16.5wt%), with N-methylpyrrolidone as a solvent, made into a uniform, stable lithium ion transmission slow-release layer coating slurry with a solid content of 5%;

[0071] (2) Apply the slurry in (1) to the negative electrode sheet substrate containing the negative active material, and form a 10 μm lithium ion transport slow-release layer after drying at 100 ° C. The ion conductivity of the sl...

Embodiment 2

[0074] This embodiment provides a negative electrode, which includes a current collector, a negative electrode active material layer, a slow-release layer, and an active lithium layer that are sequentially stacked, and the thickness of the slow-release layer is 20 μm.

[0075] The preparation method of the negative electrode is as follows:

[0076](1) Weigh lithium lanthanum titanyl oxide (LLTO), polyvinylidene fluoride-hexafluoropropylene copolymer (PVDF-HFP) and graphene according to the mass ratio of 4:1:0.5 (the mass fraction of lithium lanthanum titanyl oxide is 72.7 wt%, the mass fraction of polyvinylidene fluoride-hexafluoropropylene copolymer is 18.2wt%, and the mass fraction of graphene is 9.1wt%), with N-methylpyrrolidone as solvent, it is made into a uniform solid content of 20%. , Stable lithium ion transport slow release layer coating slurry;

[0077] (2) Coat the slurry in step (1) on the negative electrode sheet substrate containing the negative electrode activ...

Embodiment 3

[0080] This embodiment provides a negative electrode, which includes a current collector, a negative electrode active material layer, a slow-release layer, and an active lithium layer that are sequentially stacked, and the thickness of the slow-release layer is 10 μm.

[0081] The preparation method of the negative electrode is as follows:

[0082] (1) Weigh lithium lanthanum zirconium oxide (LLZO), polyethylene oxide (PEO) and conductive carbon black according to the mass ratio of 1:4:1, and use N-methylpyrrolidone as solvent (lithium lanthanum zirconium oxygen mass fraction 16.57wt%, polyethylene oxide is 67wt%, conductive carbon black is 16.5wt%), is made into the uniform, stable lithium ion transmission slow-release layer coating slurry that solid content is 5%;

[0083] (2) Apply the slurry in (1) to the negative electrode sheet substrate containing the negative electrode active material, and form a 10 μm lithium ion transport slow-release layer after drying at 120 ° C. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ionic conductivity | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com