starters for internal combustion engines

A technology of starter and internal combustion engine, which is applied in the direction of starting the engine, starting the engine with an electric motor, and the starting device with a mechanical power storage, etc., which can solve the problems of the starter pinion throwing out and the ring gear exceeding, etc., and achieves a small installation space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In the figures, the same components are denoted by the same reference numerals.

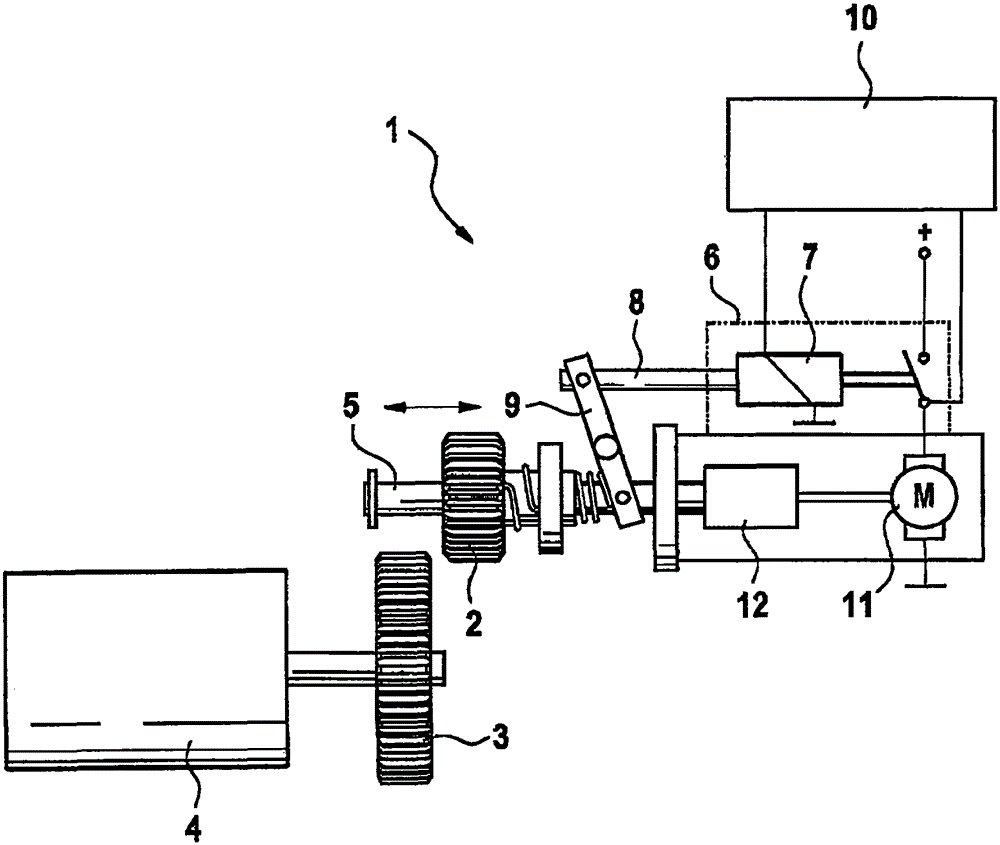

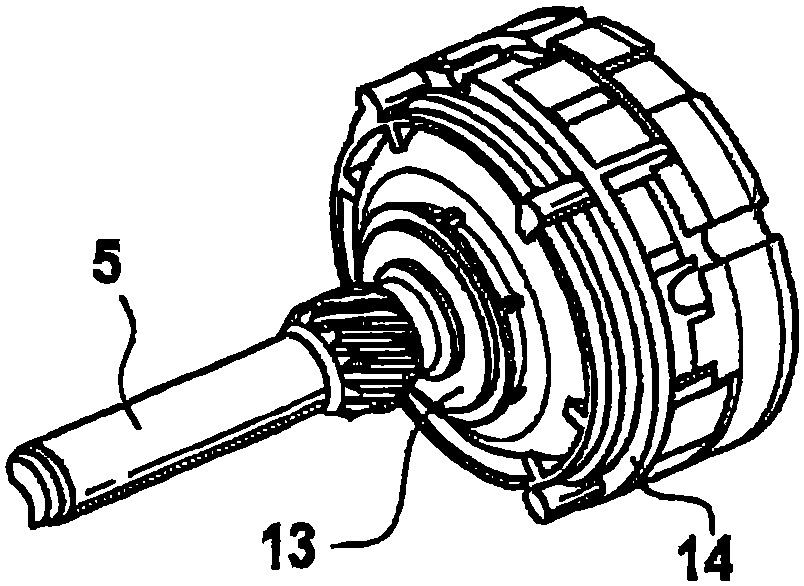

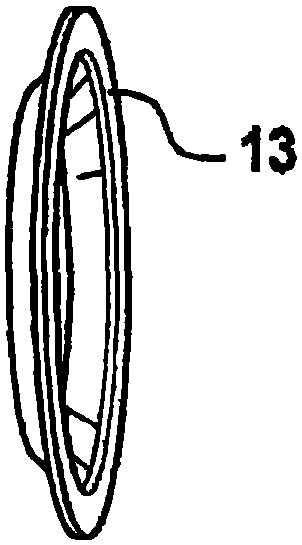

[0024] figure 1 The starter 1 for an internal combustion engine shown in , has a starter pinion 2 which meshes with a ring gear 3 of the internal combustion engine in order to start the internal combustion engine 4 . The starter pinion 2 is supported axially displaceably on the drive shaft 5 , as indicated by the double-headed arrow, wherein the starter pinion 2 is coupled to the drive shaft 5 in a rotationally fixed manner. The starter pinion 2 is adjusted between the retracted parking position and the forward meshing position with the ring gear 3 of the internal combustion engine 4 via a switch-on relay 6 which is designed electromagnetically and which comprises An energizable relay coil 7 and a reciprocating armature 8 which axially enters into the relay coil 7 when the relay coil 7 is energized. The reciprocating armature 8 forms a dynamic coupling with the starter pinion 2 via the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com