Terminal connection structure of sff 2×N series optical modules

A terminal connection and optical module technology, which is applied in the connection, parts of the connection device, protective grounding/shielding device of the connection part, etc., can solve the problems of inability to completely eliminate crosstalk, high production cost, high process requirements, etc., and improve the crosstalk problem , reduce processing costs, avoid the effect of point contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

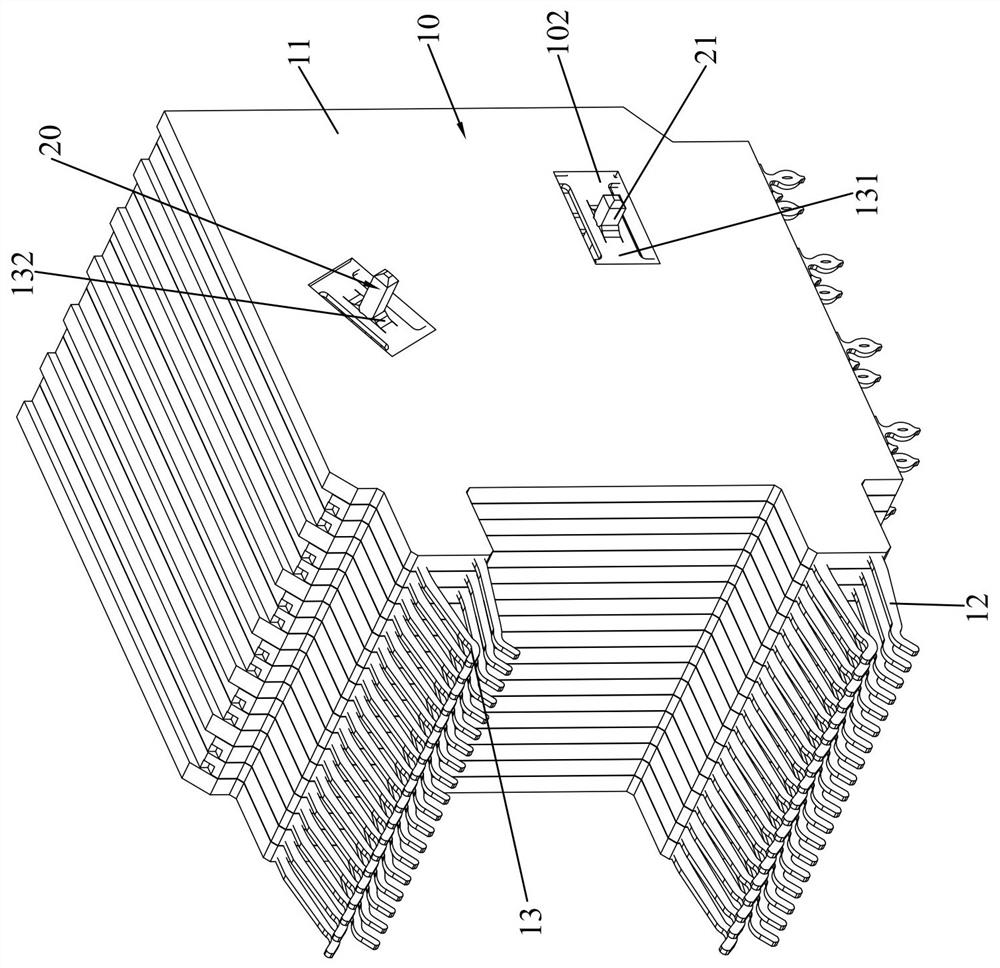

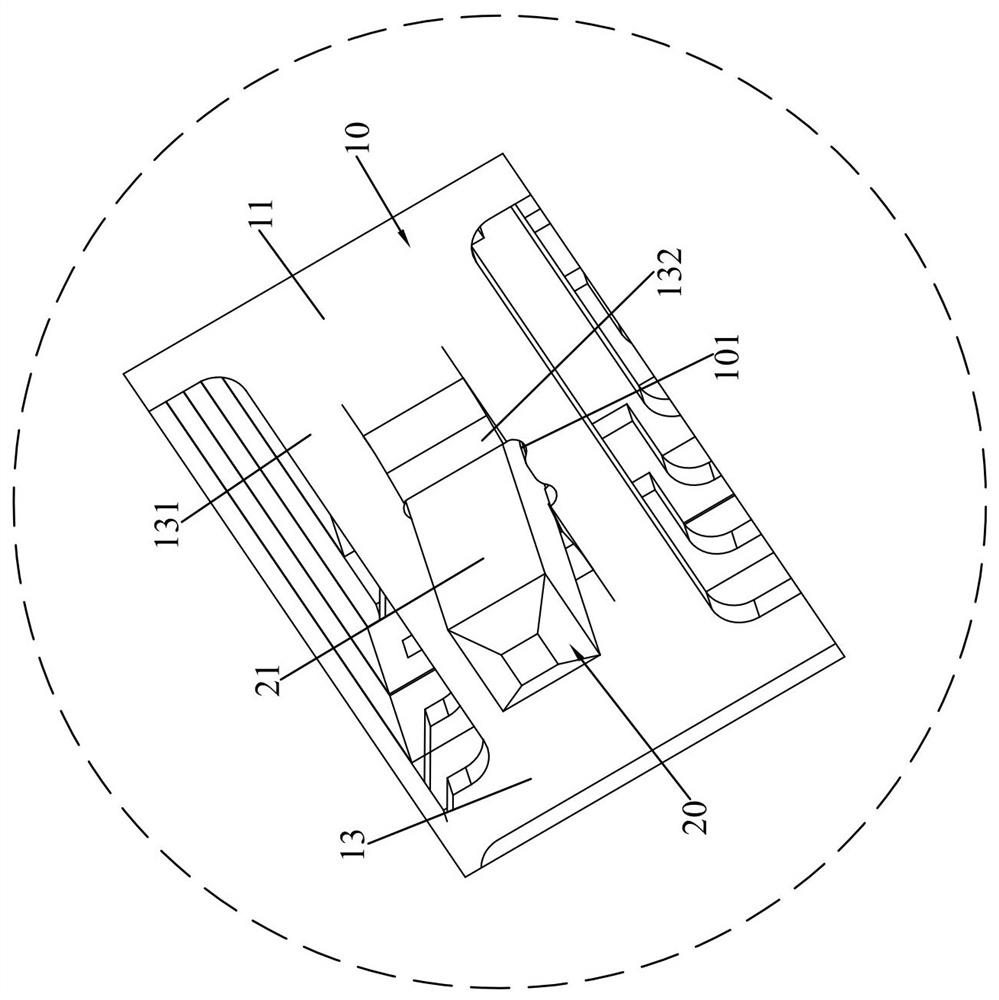

[0024] Please refer to Figure 1 to Figure 4 As shown, it shows the specific structure of the preferred embodiment of the present invention, which includes a plurality of terminal modules 10 and at least one conductive column 20 .

[0025] The plurality of terminal modules 10 are stacked together, and each terminal module 10 includes an insulating block 11 and a signal terminal 12 that is embedded and fixed with the insulating block 10, and some of the insulating blocks 11 of the terminal modules 10 are embedded and fixed. There is a ground terminal 13, a through hole 101 is opened on the fixed part 131 of the ground terminal 13, and the edge of the through hole 101 is integrally formed with a shrapnel 132; in this embodiment, the fixed part 131 of the ground terminal 13 is opened There are two aforementioned through holes 101, the two through holes 101 are staggered up and down, left and right, and the edge of each through hole 101 is integrally formed and connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com