Manufacturing method of intelligent full-color toning COB light source

A production method and light source technology, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve problems such as leakage and affecting light output of COB chips, and achieve the effect of reducing glue overflow and avoiding leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

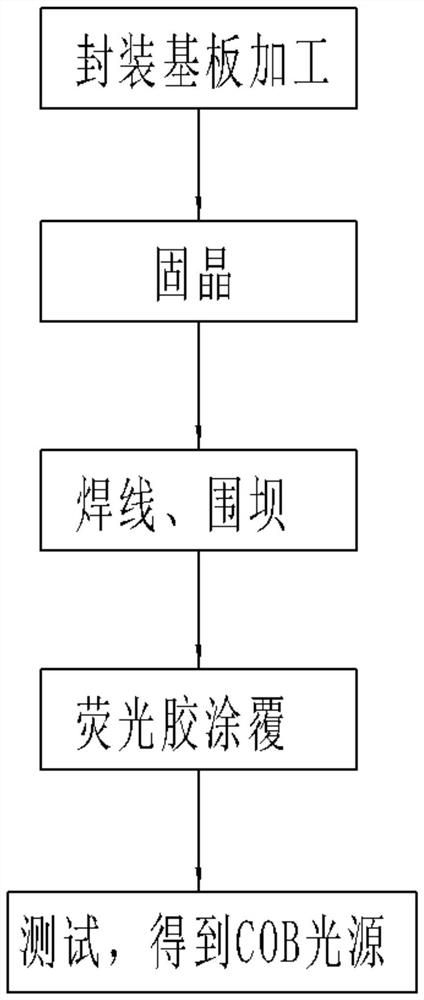

[0058] A method for manufacturing an intelligent full-color toning COB light source, comprising the following steps:

[0059] (1) Prepare the packaging substrate:

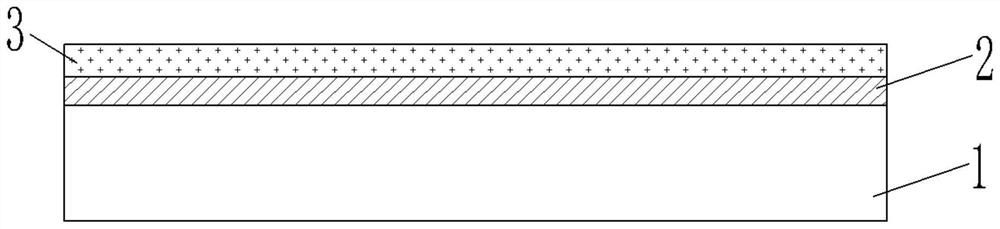

[0060] A. Take the single-sided copper-clad laminate, cut it into a preset size, and set it aside; the single-sided copper-clad laminate includes the single-sided copper-clad laminate substrate 1 and the copper plating layer 2;

[0061] B. Use a brushing machine to remove the oxide film on the surface of the copper clad laminate, coat the positive photoresist 3 on the copper plating layer 2 on the surface of the copper clad laminate, bake and cure, expose the pattern of the solid crystal area through the mask plate, and place it in the developing Develop and etch in the liquid to form several solid crystal regions;

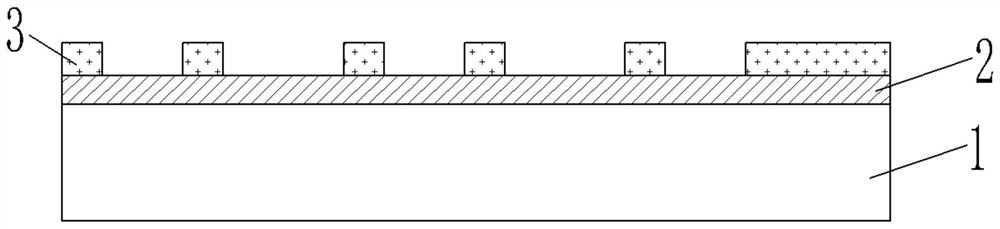

[0062] C. Place the single-sided copper-clad laminate in an ICP etching machine, perform ICP etching on the die-bonding area and form a die-bonding groove, and remove the positive photoresist; the ICP...

Embodiment 2

[0079] A method for manufacturing an intelligent full-color toning COB light source, comprising the following steps:

[0080] (1) Prepare the packaging substrate:

[0081] A. Take the single-sided copper-clad laminate, cut it into a preset size, and set it aside;

[0082] B. Use a brushing machine to remove the oxide film on the surface of the copper-clad laminate, apply a positive photoresist on the copper-plated layer 2 on the surface of the copper-clad laminate, bake and cure, expose the pattern of the crystal-bonding area through the mask plate, and place it in the developer Develop and etch in the middle to form several solid crystal regions;

[0083] C. Place the single-sided copper-clad laminate in an ICP etching machine, perform ICP etching on the die-bonding area and form a die-bonding groove; remove the positive photoresist; the ICP etching depth is a, and the thickness of the COB chip is b , the thickness of copper plating layer 2 is c, then

[0084] c+0.4b=a.

...

Embodiment 3

[0101] A method for manufacturing an intelligent full-color toning COB light source, comprising the following steps:

[0102] (1) Prepare the packaging substrate:

[0103] A. Take the single-sided copper-clad laminate, cut it into preset specifications and sizes, and set aside;

[0104] B. Use a brushing machine to remove the oxide film on the surface of the copper-clad laminate, apply a positive photoresist on the copper-plated layer 2 on the surface of the copper-clad laminate, bake and cure, expose the pattern of the crystal-bonding area through the mask plate, and place it in the developer Develop and etch in the middle to form several solid crystal regions;

[0105] C. Place the single-sided copper-clad laminate in an ICP etching machine, perform ICP etching on the die-bonding area and form a die-bonding groove; remove the positive photoresist; the ICP etching depth is a, and the thickness of the COB chip is b , the thickness of copper plating layer 2 is c, then

[010...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com