A high-performance giant electrorheological elastomer and its preparation and testing methods

An electrorheological elastomer, high-performance technology, used in the application of stable tension/pressure to test the strength of materials, measuring devices, strength characteristics, etc. Difficult to achieve and other problems, to achieve the effect of reducing the flow loss of silicone oil, high relative electrorheological effect, and enhanced interface polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] A preparation method of a high-performance giant electrorheological elastomer, the raw material composition includes electrorheological particles, conductive metal particles, PDMS prepolymer, curing agent and silicone oil; including the following steps:

[0055] a. Quantitatively take the PDMS prepolymer and the curing agent into a mortar and grind for 5-10 minutes to obtain mixture 1; the curing agent is a silicon hydrogen crosslinking agent; and / or, the PDMS prepolymer is the same The use mass ratio of described curing agent is 10:1;

[0056] b. Quantitatively take the silicone oil and add it into the mortar and grind it with the mixture 1 for 15-20 minutes to obtain the mixture 2; the silicone oil is uncrosslinked polydimethylsiloxane, and / or, the The viscosity of the silicone oil is 0.1-100cst; and / or, the degree of polymerization of the silicone oil is 13-360;

[0057] c. Quantitatively take the electrorheological particles and the flake-shaped conductive metal pa...

experiment example 1

[0081] This embodiment discloses an electrorheological elastomer, comprising electrorheological particles, conductive metal particles, PDMS polymer and silicone oil; the electrorheological particles and the conductive metal particles constitute a double dispersed phase; the PDMS polymer and the Silicone oil constitutes a bicontinuous phase; the electrorheological particles and the conductive metal particles are dispersed in the bicontinuous phase.

[0082] The material of the conductive metal particles is silver; and / or, the shape of the conductive metal particles includes flakes; and / or, the particle size of the conductive metal particles is 1-10 μm.

[0083] The giant electrorheological elastomer includes 50wt% electrorheological particles, 24wt% PDMS polymer and 26wt% silicone oil.

[0084] The electrorheological particles are barium titanyl oxalate wrapped by urea.

[0085] The PDMS polymer is polymerized by a PDMS prepolymer and a curing agent; and / or, the PDMS prepolyme...

experiment example 2

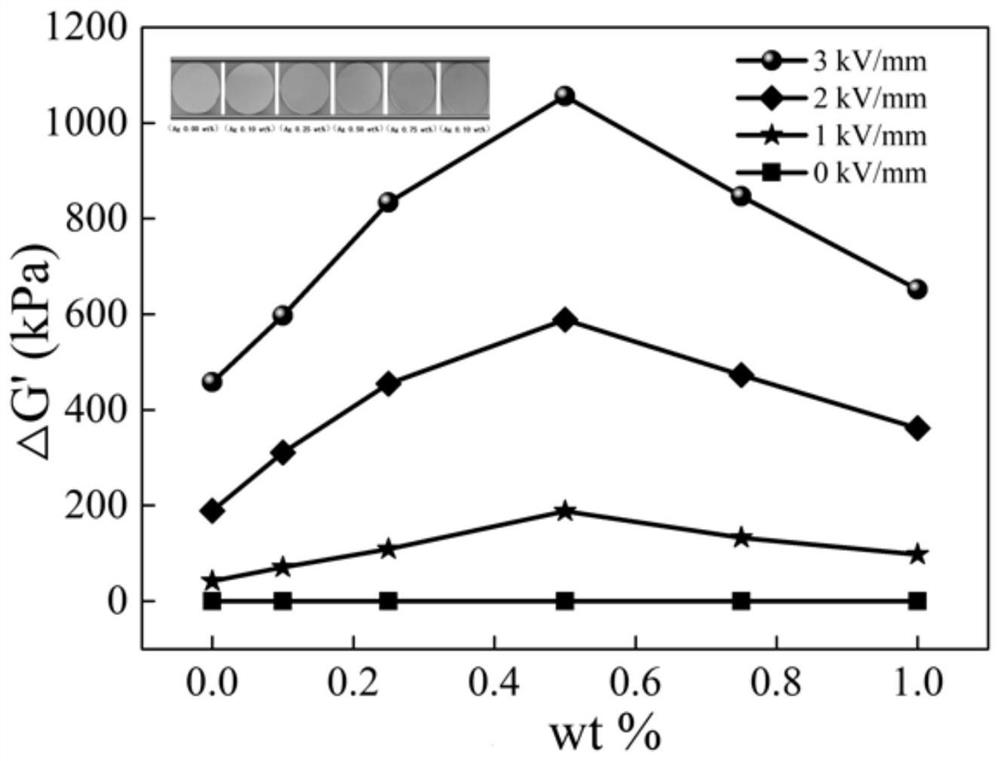

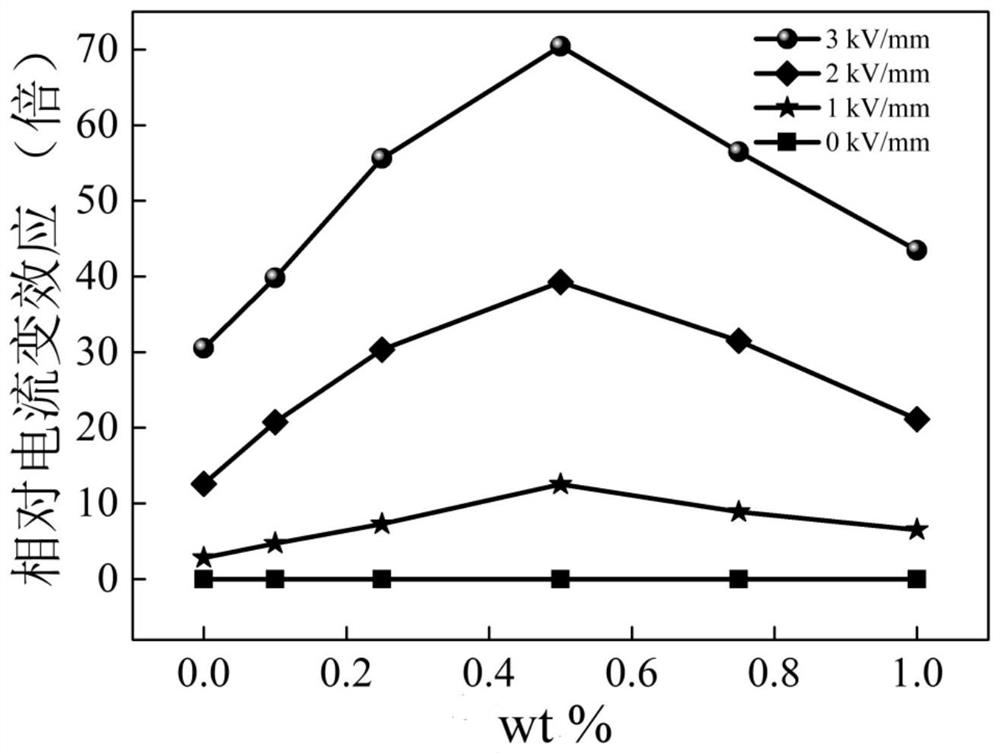

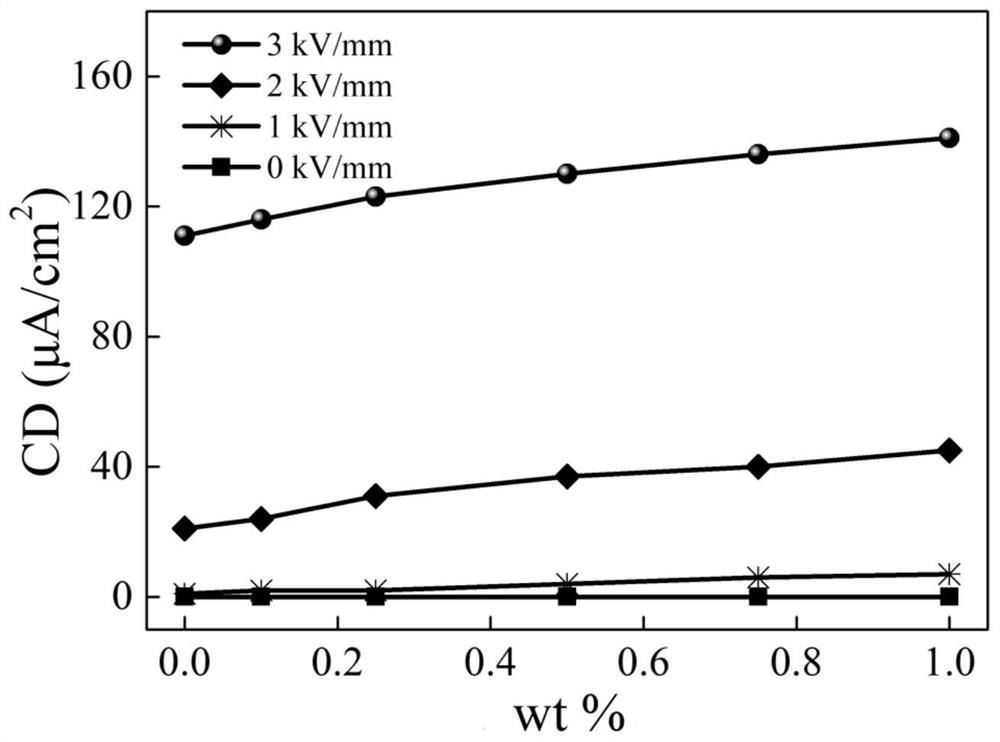

[0103] This embodiment discloses an electrorheological elastomer, which is used to verify the optimal addition ratio of conductive metal particles, shape of metal particles, electrorheological activity and time stability. The electrorheological elastomer comprises electrorheological particles, conductive metal particles, PDMS polymer and silicone oil; the electrorheological particles and the conductive metal particles form a bidisperse phase; the PDMS polymer and the silicone oil form a bicontinuous phase ; the electrorheological particles and the conductive metal particles are dispersed in the bicontinuous phase.

[0104] The addition amount of the conductive metal particles is 0wt%, 0.5wt%, 1wt% and 10wt% of the mass sum of the mixture 2 and the electrorheological particles, the conductive metal particles are gold particles, and the rest are the same as the experimental example 1.

[0105] Such as Figure 4 As shown, when an electric field is applied to the elastomer, the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com