Rigid polyvinyl chloride pipe fitting filled with superfine activated calcium carbonate and preparation method thereof

A technology of activated calcium carbonate and hard polyvinyl chloride, which is applied in the field of polyvinyl chloride materials, can solve the instability of formula components and the plasticization of production equipment materials, reduce the mechanical properties of hard polyvinyl chloride pipe fittings, and affect the plasticization To avoid problems such as material stability and fluidity, to avoid product under-injection, increase apparent density, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

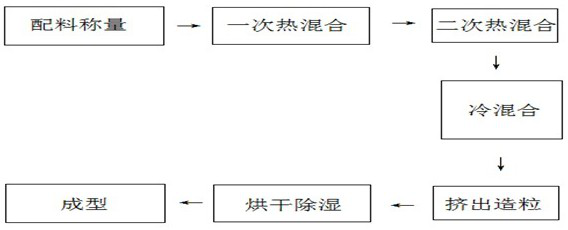

[0042] A preparation method of a rigid polyvinyl chloride pipe fitting filled with ultrafine active calcium carbonate, comprising the following steps:

[0043] (1) Weighing: Weigh the raw materials that make up the hard polyvinyl chloride pipe fittings according to the ratio, among which, the raw material ratio of the hard polyvinyl chloride pipe fittings is: 270 kg of polyvinyl chloride resin powder, 21 kg of ultrafine activated calcium carbonate 15 kg of calcium zinc stabilizer, 10.5 kg of acrylate anti-impact agent, 0.6 kg of lubricant, 3 kg of processing flow agent, 9 kg of titanium dioxide;

[0044] (2) Primary thermal mixing: Put the raw materials that make up the rigid polyvinyl chloride pipe fittings into the mixing equipment for thermal mixing. The temperature of the primary thermal mixing is 115°C, the rotational speed is 1350r / min, and the time is 10min;

[0045] (3) Secondary thermal mixing: Immediately after the first thermal mixing, perform secondary thermal mixi...

Embodiment 2

[0062] A preparation method of a rigid polyvinyl chloride pipe fitting filled with ultrafine active calcium carbonate, comprising the following steps:

[0063] (1) Weighing: Weigh the raw materials that make up the rigid polyvinyl chloride pipe fittings according to the ratio. Among them, the ratio of the raw materials that make up the rigid polyvinyl chloride pipe fittings is: 330 kg of polyvinyl chloride resin powder, 30 kg of ultrafine activated calcium carbonate 16.5 kg of calcium zinc stabilizer, 12 kg of acrylate impact modifier, 0.9 kg of lubricant, 4.5 kg of processing flow agent, 12 kg of titanium dioxide;

[0064] (2) Primary thermal mixing: Put the raw materials that make up the rigid polyvinyl chloride pipe fittings into the mixing equipment for thermal mixing. The temperature of the primary thermal mixing is 120°C, the rotational speed is 1450r / min, and the time is 15 minutes;

[0065] (3) Secondary thermal mixing: Immediately after the first thermal mixing, perfo...

Embodiment 3

[0082] A preparation method of a rigid polyvinyl chloride pipe fitting filled with ultrafine active calcium carbonate, comprising the following steps:

[0083] (1) Weighing: Weigh the raw materials that make up the rigid polyvinyl chloride pipe fittings according to the ratio. Among them, the ratio of the raw materials that make up the rigid polyvinyl chloride pipe fittings is: 300 kg of polyvinyl chloride resin powder, 24 kg of ultrafine activated calcium carbonate 15.6 kg of calcium zinc stabilizer, 11.1 kg of acrylate impact modifier, 0.75 kg of lubricant, 3.6 kg of processing flow agent, 10.5 kg of titanium dioxide;

[0084] (2) One-time thermal mixing: Put the raw materials that make up the rigid polyvinyl chloride pipe fittings into the mixing equipment for thermal mixing. The temperature of the primary thermal mixing is 118°C, the speed is 1400r / min, and the time is 13min;

[0085] (3) Secondary thermal mixing: Immediately perform secondary thermal mixing after the prim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oil absorption value | aaaaa | aaaaa |

| oil absorption value | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com