Monofluoromethylselenylation reagent as well as preparation method and application thereof

A technology of methylthio group and dimethylamino group, which is applied in the field of organic synthesis, can solve problems such as few reports of monofluoromethylselenyl group, and achieves the effects of mild conditions, short steps and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

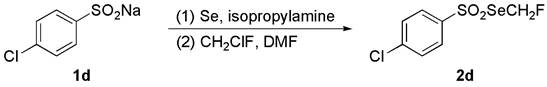

Embodiment 1

[0027] Operation steps: (1) Add 1.0 mmol of sodium benzenesulfinate, 1.0 mmol of selenium powder, and 0.5 mL of diethylamine in turn to a round-bottomed flask, and stir at room temperature for 12 h to stop the reaction. Post-treatment: suck out the supernatant, filter the residual solid with suction, wash the solid with 3×10 mL ether, and dry it to obtain sodium selenobenzenesulfonate. (2) Add sodium selenobenzenesulfonate, 2.0mL, into a single-necked flask N , N -Dimethylformamide, seal the bottle stopper, put on the air balloon and take out the air in the flask, and then fill it with chlorofluoromethane gas. Put the reaction bottle into an oil bath at 80°C and stir for 5 hours, stop the reaction, and cool to room temperature. Post-processing: extract the reaction liquid 5 times with ethyl acetate and water, wash 3 times with saturated saline, dry over anhydrous sodium sulfate, remove the solvent by rotary evaporation under reduced pressure, and purify the residue through a...

Embodiment 2

[0031]Operation steps: (1) Add 1.0 mmol sodium p-toluenesulfinate, 1.0 mmol selenium powder, and 0.5 mL triethylamine in turn to a round-bottomed flask, and stir at room temperature for 12 h to stop the reaction. Post-processing: suck out the supernatant, filter the residual solid with suction, wash the solid with 3×10 mL ether, and dry it to obtain sodium seleno-p-toluenesulfonate. (2) Add sodium selenide p-toluenesulfonate, 2.0 mL, into a single-necked flask N , N -Dimethylformamide, seal the bottle stopper, put on the air balloon and pump out the air in the flask, then fill it with chlorofluoromethane gas until it is observed that the balloon is under normal pressure. Put the reaction bottle into an oil bath at 80°C and stir for 5 hours, stop the reaction, and cool to room temperature. Post-processing: extract the reaction liquid 5 times with ethyl acetate and water, wash 3 times with saturated saline, dry over anhydrous sodium sulfate, remove the solvent by rotary evapor...

Embodiment 3

[0035] Operation steps: (1) Add 1.0 mmol of sodium p-fluorobenzenesulfinate, 1.0 mmol of selenium powder, and 0.5 mL of diethylamine in turn to a round-bottomed flask, and stir at room temperature for 12 h to stop the reaction. Post-treatment: suck out the supernatant, filter the residual solid with suction, wash the solid with 3×10 mL ether, and dry it to obtain sodium seleno-p-fluorobenzenesulfonate. (2) Add sodium seleno-p-fluorobenzenesulfonate, 2.0 mL, into a single-necked flask N , N -Dimethylacetamide, seal the bottle stopper, put on the air balloon and suck out the air in the flask, then fill it with chlorofluoromethane gas until it is observed that the balloon is under normal pressure. Put the reaction bottle into an oil bath at 80°C and stir for 5 hours, stop the reaction, and cool to room temperature. Post-treatment: extract the reaction liquid 5 times with ethyl acetate and water, wash 3 times with saturated saline, dry over anhydrous sodium sulfate, remove the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com