Preparation method and system of trimethylsilylamine

A trisilyl amine, preparation system technology, applied in the direction of chloride preparation, chemical instruments and methods, chemical/physical/physicochemical process of energy application, etc., can solve multi-solid by-product ammonium chloride, synthesis process and Problems such as high device complexity and high separation difficulty achieve the effect of being conducive to large-scale industrial production, low product separation difficulty, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 3

[0050] Embodiment 1 Trisilylamine preparation system

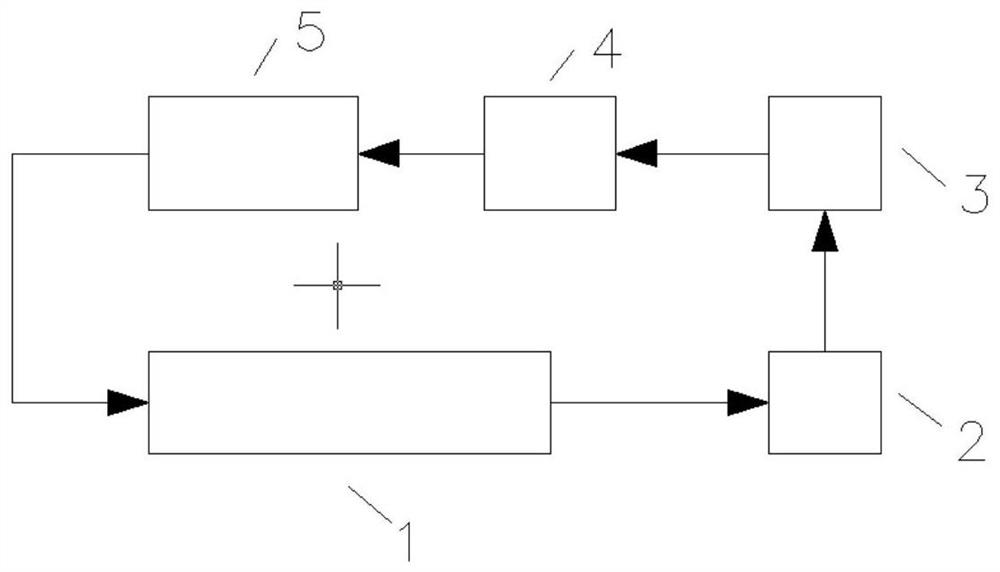

[0051] A preparation system for trisilylamine, such as figure 1 Shown, comprise reactor 1, primary cooler 2, secondary cooler 3, absorption tank 4, drier 5, described reactor 1, primary cooler 2, secondary cooler 3, absorption tank 4, The dryers 5 are connected in sequence; the discharge end of the dryer 5 communicates with the feed end of the reactor 1 .

[0052] Wherein, the reactor 1 is a plasma reactor, which may be any plasma reactor commonly used in the art, such as a DBD reactor, an arc discharge plasma reactor, and the like.

Embodiment 2 3

[0053] The preparation of embodiment 2 trisilylamine

[0054] The preparation system of Example 1 is used to prepare trisilylamine, wherein the reactor 1 is a DBD reactor with a conventional coaxial cylindrical structure in the art, and the surface of the electrode in the reactor is provided with an insulating layer, and the electrode is not directly in contact with the reaction gas. . The surface of the insulating layer on the inner wall of the outer electrode is covered with a barium sulfate layer with a roughness of 0.5 μm as a reflective film layer.

[0055] Will N 2 :H 2 : SiCl 2 h 2 N with a molar ratio of 20:20:1 2 :H 2 : SiClH 3 The mixed gas is introduced into the DBD reactor, the pressure formed by the mixed gas in the reactor is 0.05MPa, the working voltage of the DBD reactor is set to 10KV, and the frequency is 50KHz, so that the mixed gas can fully react in the reaction chamber and control the reaction during the reaction process. The temperature of the no...

Embodiment 3 3

[0060] The preparation of embodiment 3 trisilylamine

[0061] The preparation system of Example 1 is used to prepare trisilylamine, wherein the reactor 1 is a DBD reactor with a conventional coaxial cylindrical structure in the art, and the surface of the electrode in the reactor is provided with an insulating layer, and the electrode is not directly in contact with the reaction gas. . The surface of the insulating layer on the inner wall of the outer electrode is covered with a barium sulfate layer with a roughness of 0.5 μm as a reflective film layer.

[0062] Will N 2 :H 2 : SiCl 2 h 2 N with a molar ratio of 20:20:1 2 :H 2 : SiClH 3 The mixed gas is introduced into the DBD reactor, the pressure formed by the mixed gas in the reactor is 0.05MPa, the working voltage of the DBD reactor is set to 50KV, and the frequency is 50KHz, so that the mixed gas can fully react in the reaction chamber and control the reaction during the reaction process. The temperature of the no...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com