Construction method for long-distance high-lifting underground excavation tunnel

A technology for tunnel construction and construction methods, applied in tunnels, earthwork drilling, mining equipment, etc., can solve the problems of long construction period and large interference of existing structures, and achieve the goal of reducing mechanical handling costs, shortening construction period and ensuring construction safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

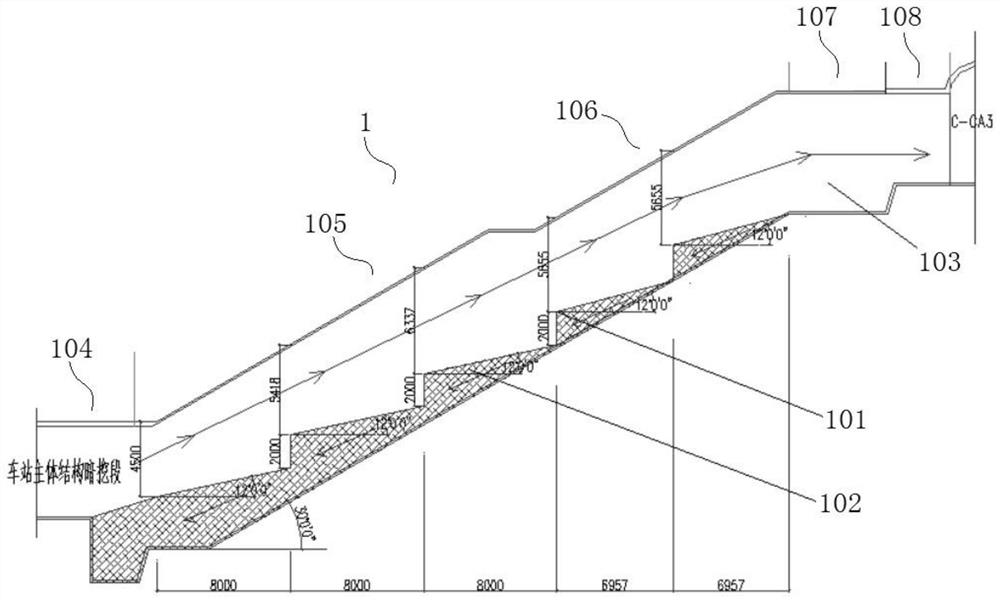

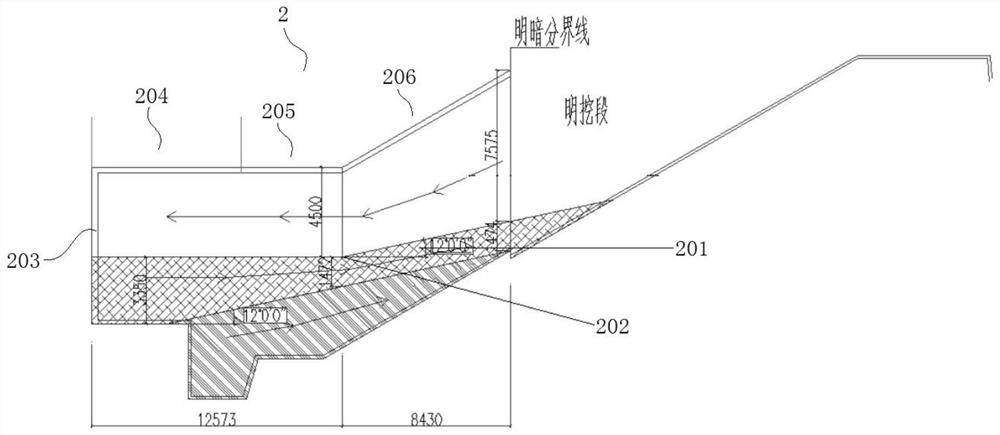

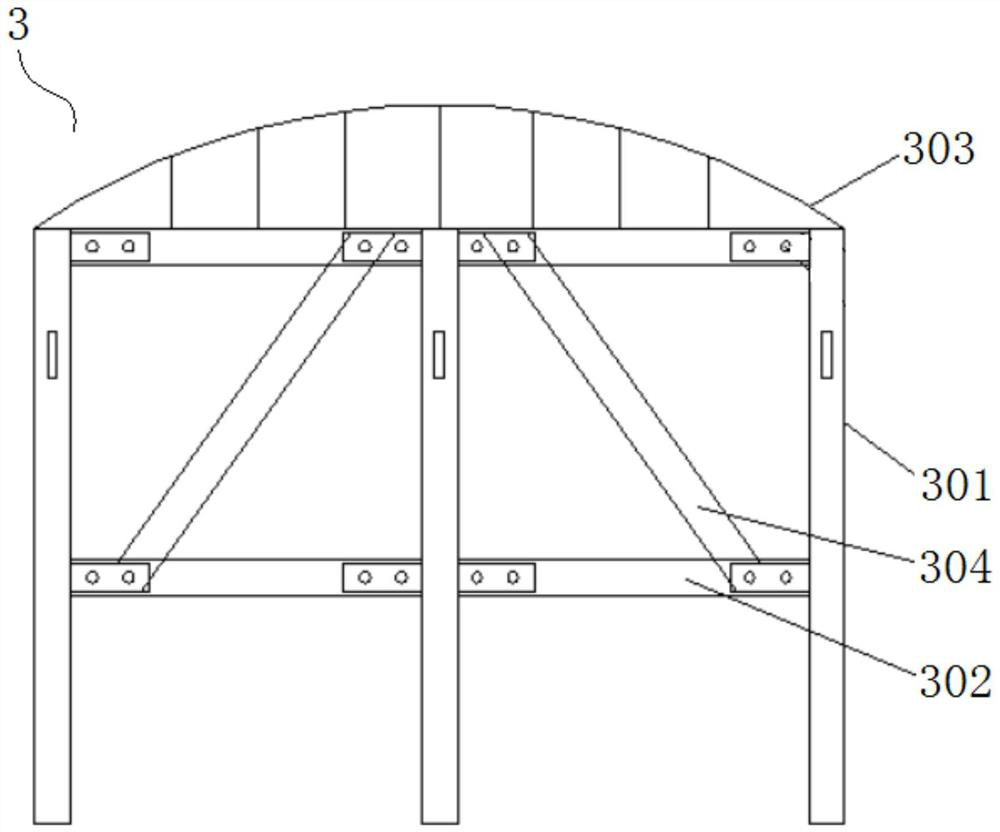

[0049] see Figure 1 to Figure 4 shown;

[0050] The construction method of the long-distance high-elevation underground excavation tunnel in this embodiment mainly includes the following steps:

[0051] S1. Lifting construction of the first section 1 of the underground excavation tunnel;

[0052] S2. Lifting construction of the second section 2 of the underground excavation tunnel;

[0053] Wherein, in step S1, the first section of trimming step 101 is formed by digging upwards from the underground excavation, and the design slope of the first section of trimming step 101 is 30°, and the surface of the first section of trimming step 101 has a first section of slope 102. The angle between the first slope 102 and the horizontal plane is 12°;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com