Optimization method of workshop facility layout based on improved artificial bee colony algorithm

A technology of artificial bee colony algorithm and layout optimization, applied in computing, computing models, data processing applications, etc., can solve problems such as NP difficulty and the inability of mathematical methods to obtain good solution results, so as to reduce transportation costs and optimize design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

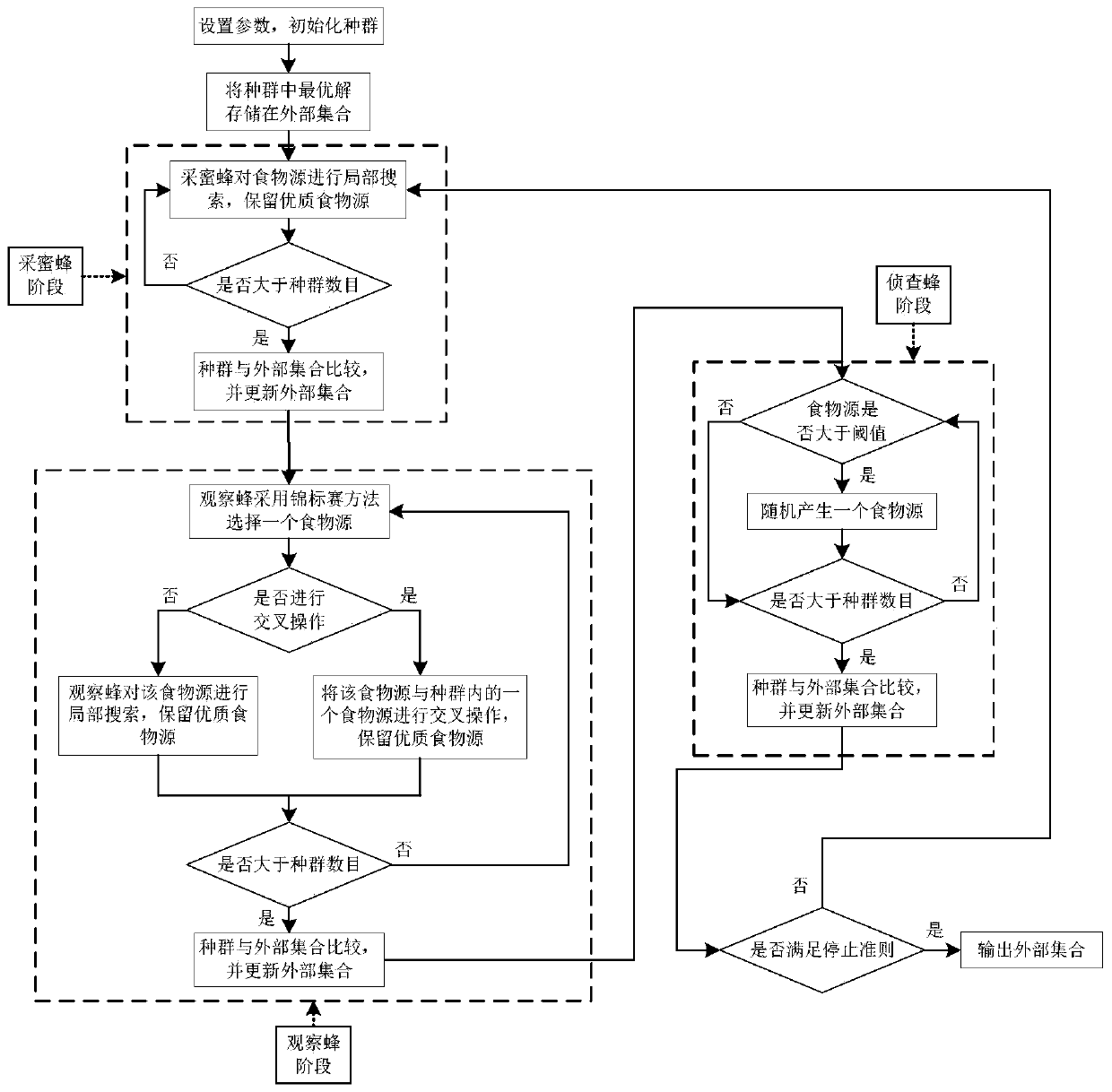

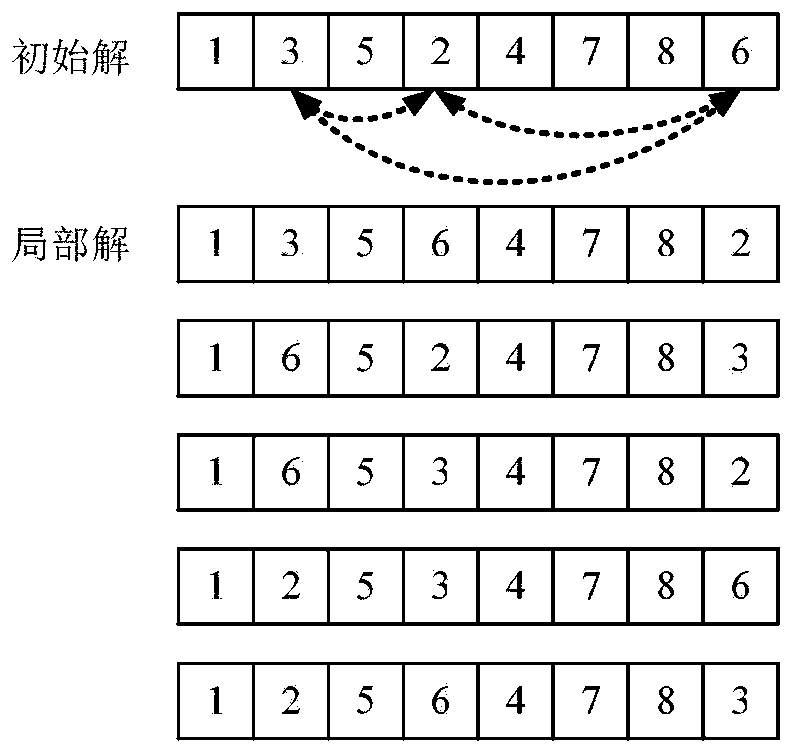

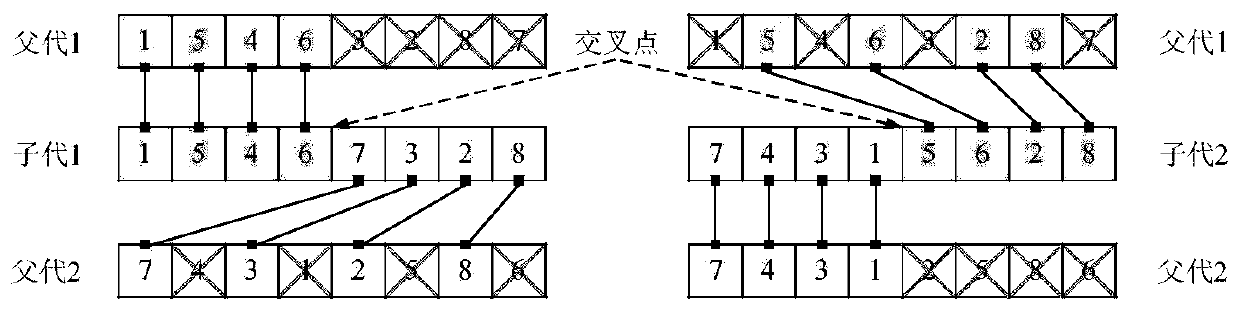

Method used

Image

Examples

Embodiment

[0045]A machinery manufacturing company needs to design the facility layout of the machining workshop. There are 15 kinds of processing parts, and there are 8 processing units. The 8 units carry out 8 different processing procedures respectively, and the 8 procedures are represented by A to H respectively. In order to meet the demand of workshop processing parts output, it is necessary to calculate the number of equipment in each processing unit. After the processing equipment in the unit is determined, the area occupied by the unit can also be determined. The machining workshop can be simplified as a single-line equipment layout problem, and the width direction of each processing unit is also consistent, so the logistics transportation distance in the length direction can represent the logistics transportation distance for parts processing. In the layout design process of the machining workshop, the logistics flow between processing units and the cost of logistics flow per u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com