Polymer building material for 3D printing

A building material, 3D printing technology, applied in the direction of additive processing, etc., to achieve the effect of shortening the construction period, fast curing, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

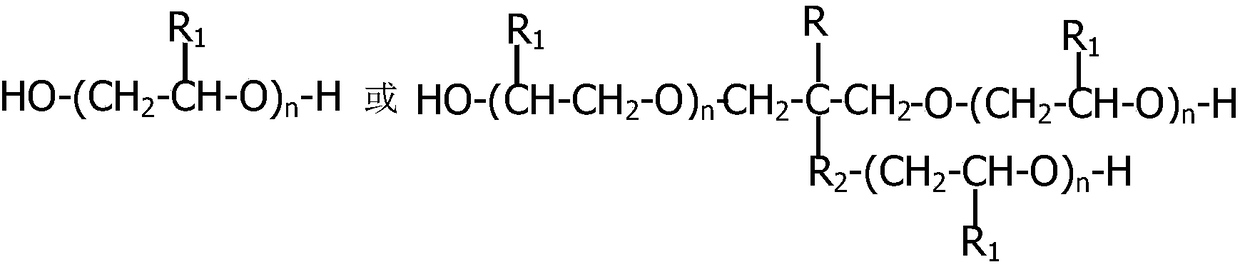

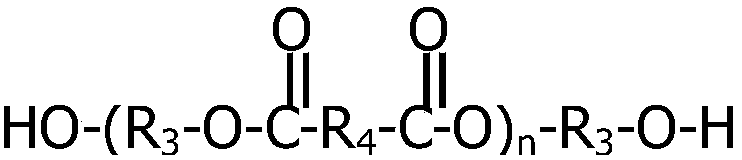

Method used

Image

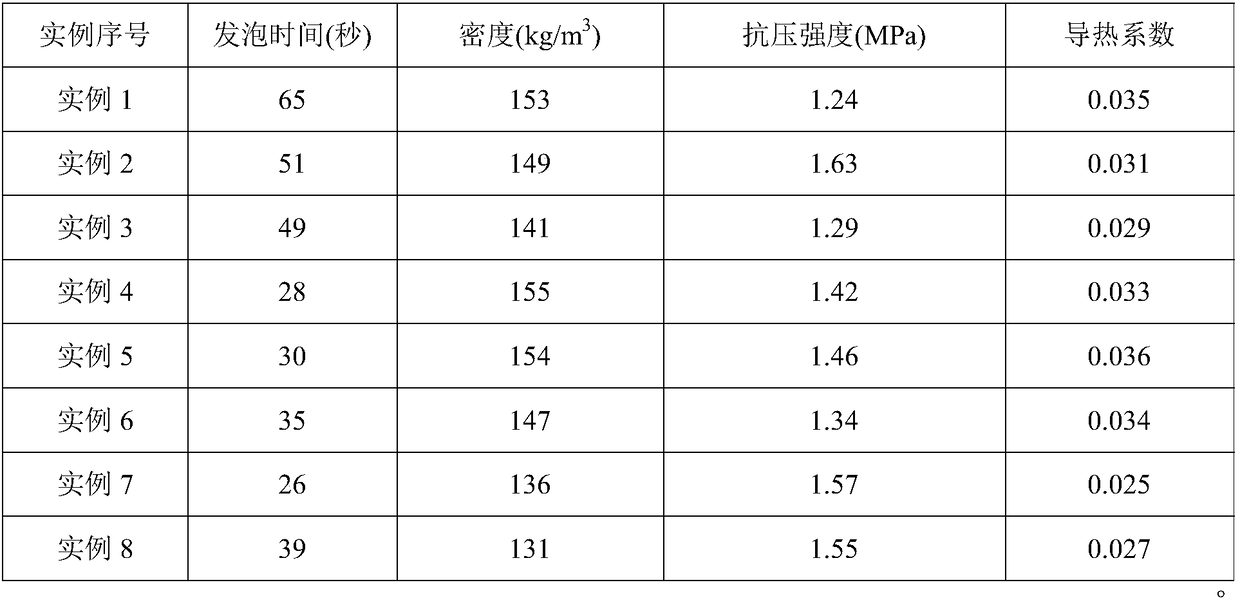

Examples

Embodiment 1

[0045] Component A: Liquefied diphenylmethane diisocyanate (MDI). Component B: 27 parts of trimethylolpropane, 18 parts of glycerin, 300 parts of polypropylene glycol (500), 20 parts of polyethylene glycol (200), 2 parts of water, 5 parts of OP-10, dibutyltin dilaurate ( DBTDL) 4 parts, phosphate tris (2-ethylhexyl) ester 2 parts. Mix components A and B evenly at a mass ratio of 1:1.5 to obtain a uniform and fine rigid foam.

Embodiment 2

[0047]Component A: Liquefied diphenylmethane diisocyanate (MDI). Component B: 27 parts of trimethylolpropane, 12 parts of diethylene glycol, 300 parts of polypropylene glycol (500), 20 parts of polyethylene glycol (200), 3 parts of water, 4 parts of OP-10, dichlorodiphenyl 6 parts of methane diamine (MOCA), 4 parts of diethylene triamine (DABCO), 3 parts of (2-ethylhexyl)-diphenyl phosphate. Mix components A and B evenly at a mass ratio of 1:1.2 to obtain a uniform and fine rigid foam.

Embodiment 3

[0049] Component A: Polymethylene polyphenyl polyisocyanate (PAPI). Component B: 24 parts of trimethylolpropane, 10 parts of glycerin, 280 parts of polypropylene glycol (500), 1 part of water, 2 parts of OP-10, 2 parts of polysiloxane, 4 parts of diphenylmethanediamine (DDM) 3 parts, 3 parts of diethylenetriamine (DABCO), 2 parts of tris(2,3-dibromopropyl) phosphate. Mix components A and B evenly at a mass ratio of 1:1.3 to obtain a uniform and fine rigid foam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com