Fast, energy-saving and environmentally-friendly glass breaking and melting device

An energy-saving and environmental protection, glassware technology, applied in glass production, glass furnace equipment, glass manufacturing equipment and other directions, can solve the problems of bulky body, complex structure, occupying space and other problems, and achieve comprehensive economic benefits and environmental protection benefits. The effect of storing space and saving handling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

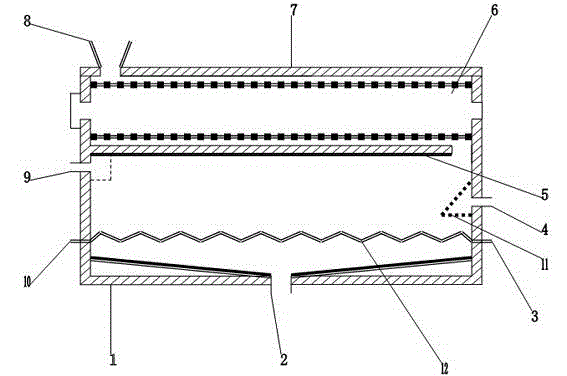

[0018] Set the quick, energy-saving and environment-friendly broken molten glass utensil of the present invention on the desired site and respectively connect the crushing roller 6, the negative rod 3 and the positive rod 10 to the external driver and the power supply, and then put the waste glass to be processed from the throwing hopper 8 into the space above the crushing roller 6, and start the crushing roller 6 to break the glass, and the broken glass is discharged from the lower discharge port opened on one side of the grinding partition 5 to the two ends of the inner bottom of the outer casing 1 and the negative electrode rod 3 and the positive electrode respectively. On the heating rod connected to the rod 10, turn on the power switch at this time, under the continuous action of the heating rod between the positive rod 10 and the negative rod 3, the broken glass will melt at the melting point, and the melted glass fluid will pass through The pure glass fluid is discharged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com