Detachable mattress and manufacturing method thereof

A detachable, mattress technology, used in mattresses, spring mattresses, filled mattresses, etc., can solve the problems of difficult handling, complex structure, high freight costs, etc., and achieve convenient industrialized mass production and good interchangeability of components. , The effect of simplifying the structure of the mattress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below by example in conjunction with accompanying drawing, the present invention will be further elaborated:

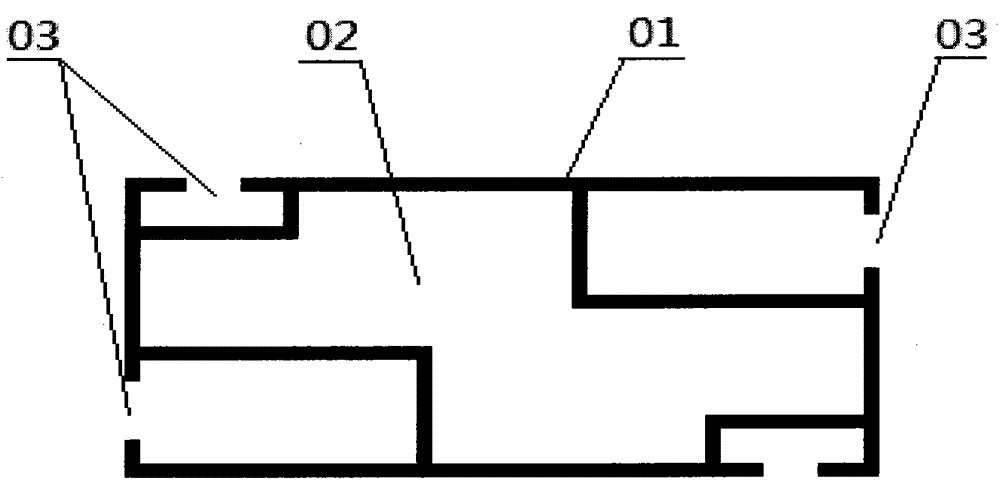

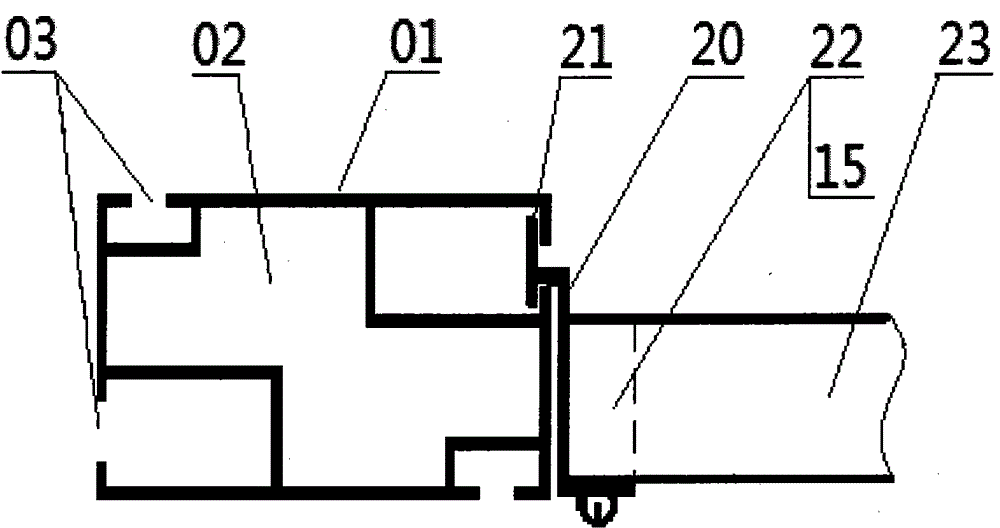

[0015] figure 1 It is a schematic diagram of the section structure of the hollow profile of the present invention. (01) in the figure is a hollow profile, the appearance is hollow (02) long strip, made of metal alloy or engineering plastic hot extrusion, at least one longitudinal, parallel to the axis, opening direction Outer "T" shape or "Ω" shape or "dovetail" shape mounting groove (03).

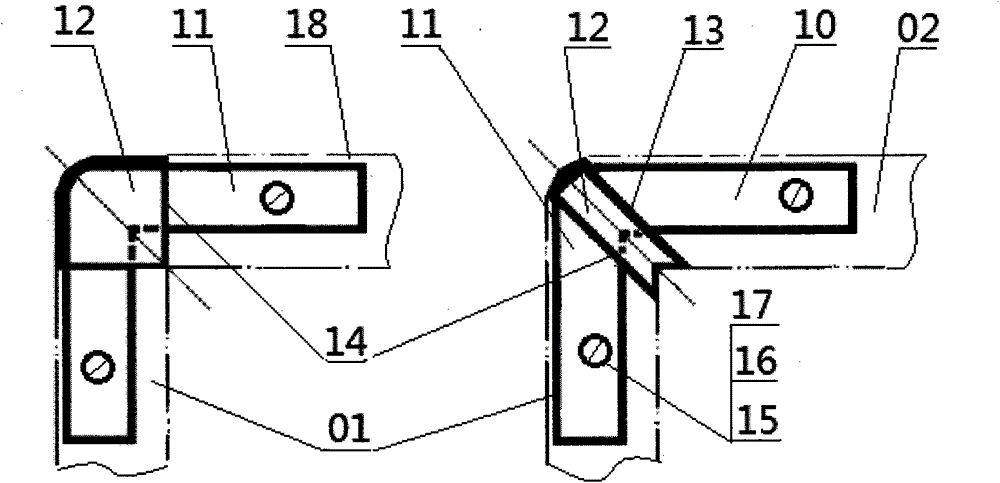

[0016] figure 2 It is a schematic diagram of the installation structure of the corner connector of the present invention. (10) in the figure is a corner connector, the appearance of which is in the shape of a curved ruler. The two arms (11) are opened at an angle and inserted into the hollow (02) of the hollow profile (01). 11) The intersecting corners are provided with a quarter-round platform or a ring-shaped protrusion (12), and the side surfaces (13) of the protrus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com