Method for synthesizing high-purity sucrose monoester

A sucrose monoester, high-purity technology, applied in the field of sucrose ester manufacturing, can solve the problems of low monoester content, difficult to reach medical consumption, toxic solvents, etc., and achieve the effect of preventing caramelization reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for synthesizing high-purity sucrose monoesters, carried out as follows:

[0031] Step 1: Put sucrose, high-grade fatty acid ester, high-grade fatty acid salt, and catalyst in a high-energy ball mill for dry milling, the ball milling speed is 400r / min, the ball milling time is 5 hours, the protective atmosphere is nitrogen, and the ball mill is mixed evenly to obtain a mixture. Among them, the higher fatty acid ester is methyl stearate, the higher fatty acid salt is potassium stearate, the molar ratio of sucrose to higher fatty acid ester is 1:1, and the quality of higher fatty acid salt is sucrose and higher fatty acid ester. 10% of the total mass, the rest is catalyst, the catalyst is mixed with potassium carbonate and potassium hydroxide in a molar ratio of 1:2, and the molar ratio of potassium ion and sucrose in the catalyst is 2:5;

[0032] Step 2: Add the ball-milled mixture into a three-necked flask, and preheat it in a vacuum oven at 70°C for 1.5 hours;...

Embodiment 2

[0039] The difference between this embodiment and the above-mentioned Embodiment 1 is that:

[0040] Step 3: the preheated mixture is placed in an induction furnace for heating and stirring, the protective atmosphere is nitrogen, the heating temperature is 110 ° C, and the stirring is performed for 5 hours, the stirring speed is 400 r / min, and the reaction pressure is 1.5 kPa to obtain a crude product;

[0041] Other conditions remain unchanged.

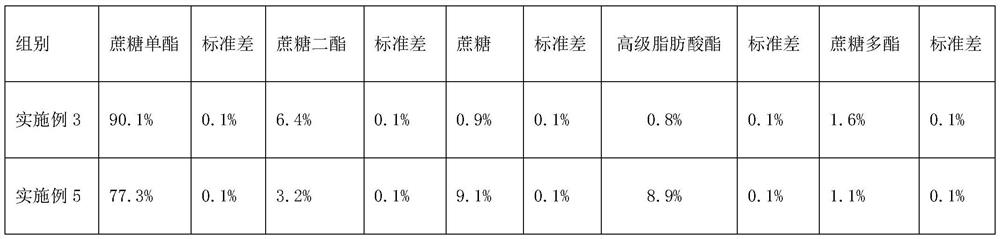

Embodiment 3

[0043] The difference between this embodiment and the above-mentioned Embodiment 1 is that:

[0044] Step 3: The preheated mixture is placed in an induction furnace for heating and stirring, the protective atmosphere is argon gas, the heating temperature is 100 ° C, and stirring is performed for 3 hours, the stirring speed is 400 r / min, and the reaction pressure is 1.5 kPa to obtain a crude product ;

[0045] Other conditions remain unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com