Method for preparing powdery low fructosan

A technology of fructooligosaccharides and powder, which is applied in the direction of oligosaccharides, lighting and heating equipment, drying solid materials, etc. Low yield and other problems, to achieve the effect of preventing caramelization reaction, convenient operation and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

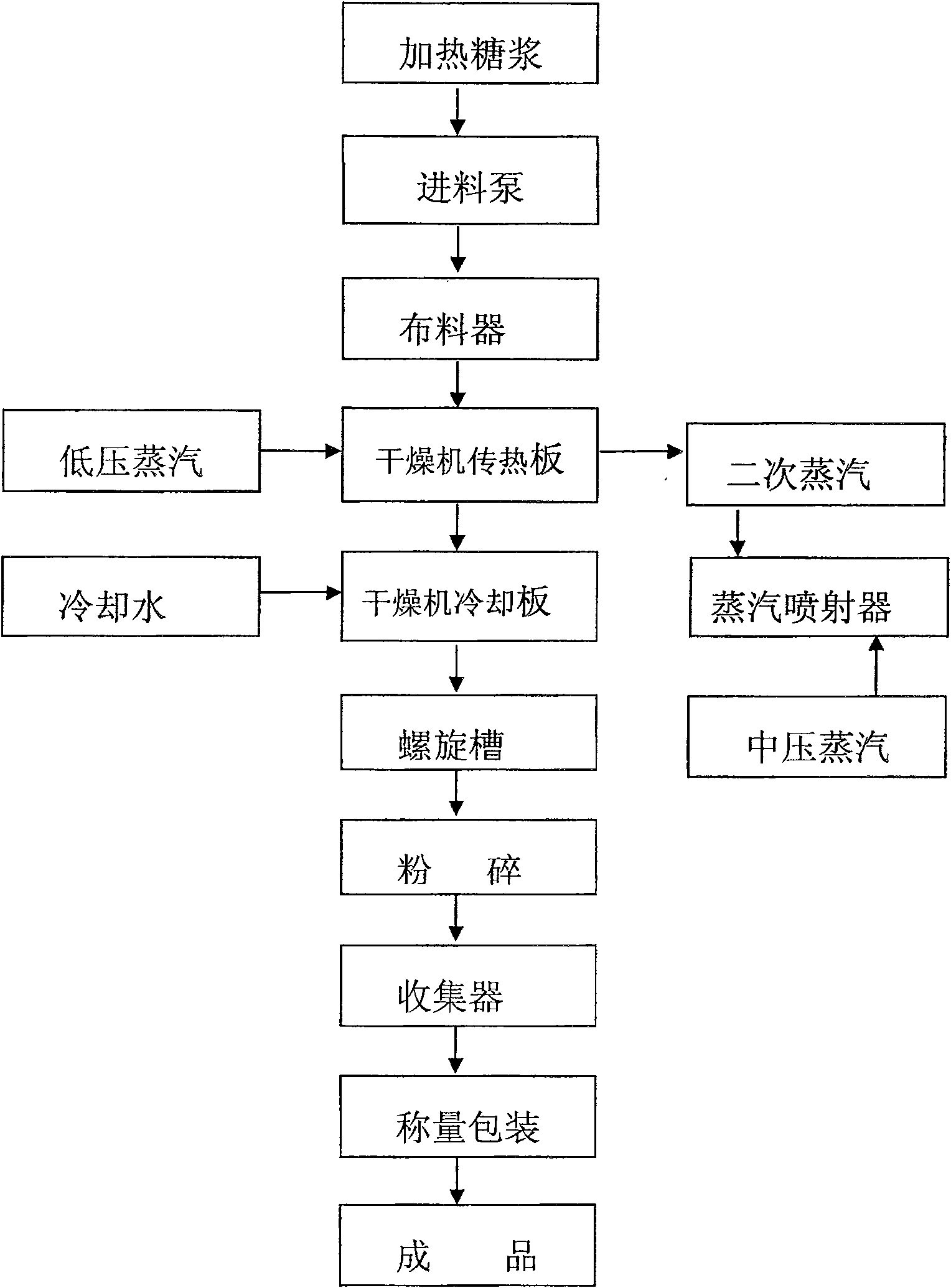

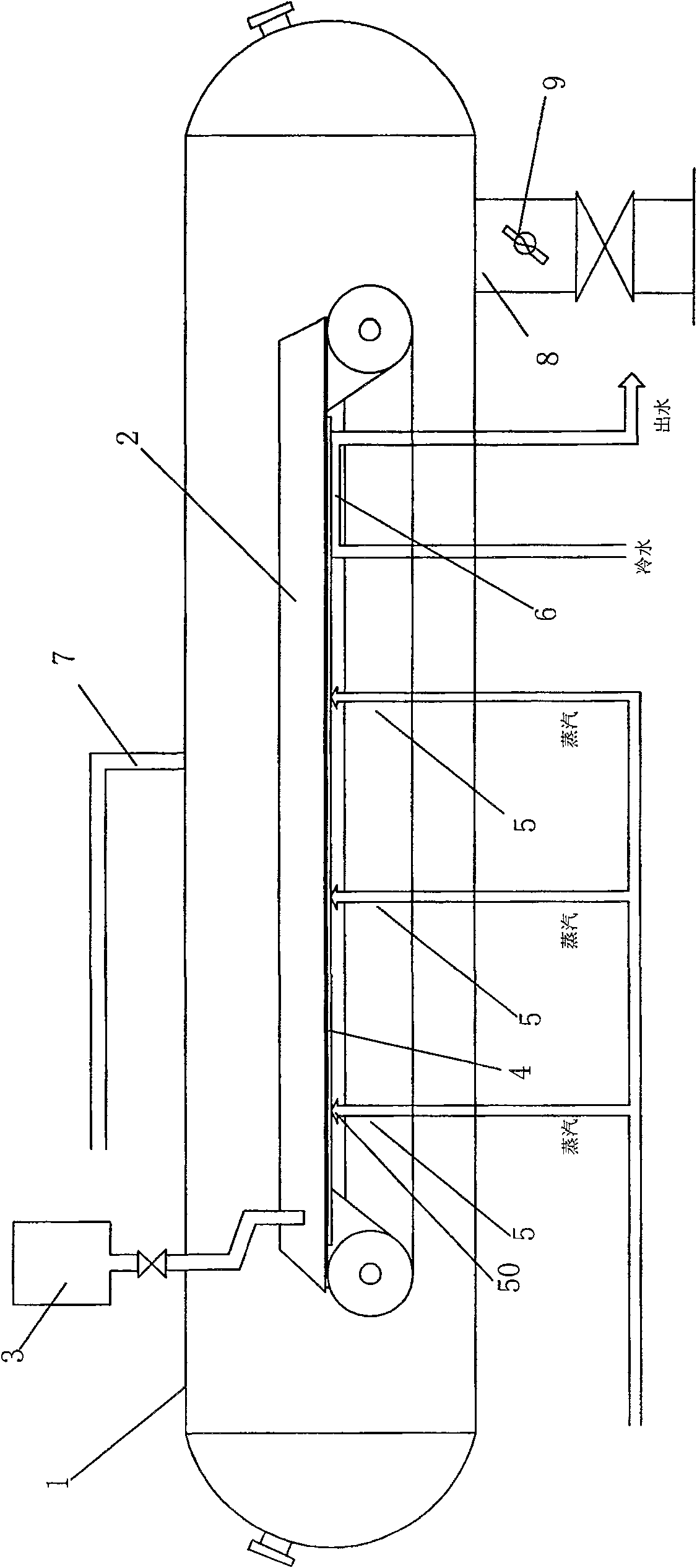

Method used

Image

Examples

specific Embodiment

[0036]Heat 260Kg of 75.2Brix fructooligosaccharide syrup to 60°C; pump the heated syrup into the feed distributor of the vacuum low-temperature continuous dryer, control the feed temperature at 60°C, adjust the negative pressure inside the belt dryer to -20mbar, and the temperature of the heating zone The temperature is 80°C, the temperature in the cooling zone of the drying belt is 35°C, the rotation angle of the swinging distributor is 90°C, the rotation speed is 10 times / min, and the crawler transmission speed is 0.2M / min. 40-110 mesh amorphous powdered fructooligosaccharide products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com