Preparation method of four-arm anti-permeability compacting agent

A technology of compacting agent and anti-seepage agent, which is applied in the field of preparation of four-arm anti-seepage compacting agent, can solve the problems of defoaming agent affecting concrete volume change, large cracks, concrete strength, etc., and achieves high practical economic value and wide sources , Improve the effect of anti-seepage ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Among them, 1,3-bis(N,N-diglycidylaminomethyl)cyclohexane was purchased from Jiangsu Xinnaxi Epoxy S-610.

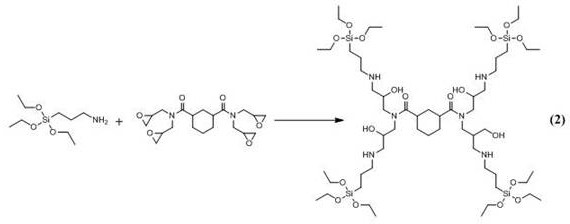

[0024]Step S1, dissolving the silane coupling agent in the solvent, and mixing evenly to obtain a silane coupling agent solution, the mixing temperature is 28°C; the silane coupling agent is KH-550, and the silane coupling agent is mixed with organic The molar volume ratio of the solvent is 0.3mol / L; the solvent is dichloromethane; step S2, adding 1,3-bis(N,N-diglycidylaminomethyl)cyclohexane dropwise to step S1 In the obtained silane coupling agent solution, control the reaction temperature at 20°C for 2 hours, then control the reaction temperature at 40°C for 3 hours, and remove the solvent by rotary evaporation to obtain the four-arm anti-penetration agent. 1,3-bis(N , when N-diglycidylaminomethyl)cyclohexane is added dropwise in the silane coupling agent, the molar ratio of the functionalized monomer and the silane coupling agent is controlled to be 5:1; step ...

Embodiment 2

[0026] 2,2'-dimethyl-3,3',5,5'-triphenylmethane tetraisocyanate was purchased from Jiangsu Hengbang 7900 curing agent TPMMTIA type. Step S1, the mixing temperature is 25°C, dissolve the silane coupling agent in the solvent, and mix uniformly to obtain a silane coupling agent solution; the silane coupling agent is KH-792, and the silane coupling agent is mixed with organic The molar volume ratio of the solvent is 2mol / L; the solvent is xylene; step S2, adding 2,2'-dimethyl-3,3',5,5'-triphenylmethane tetraisocyanate dropwise Into the silane coupling agent solution obtained in step S1, control the reaction temperature at 20°C for 1 hour, and then control the reaction temperature at 30°C for 2 hours to obtain the four-arm anti-penetration agent. Add 7900 curing agent dropwise to the silane coupling agent When in the joint agent, control the molar ratio of the 7900 curing agent to the silane coupling agent to be 4:1; step S3, the temperature is 25°C, prepare the nano-silica aqueous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com