A processing method for superhydrophobic slanted column arrays of droplet lateral pie bouncing

A processing method and super-hydrophobic technology, applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problems of limited preparation materials, expensive lithography equipment, complicated preparation process, etc., and achieve controllable inclination angle and processing range. Wide, high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

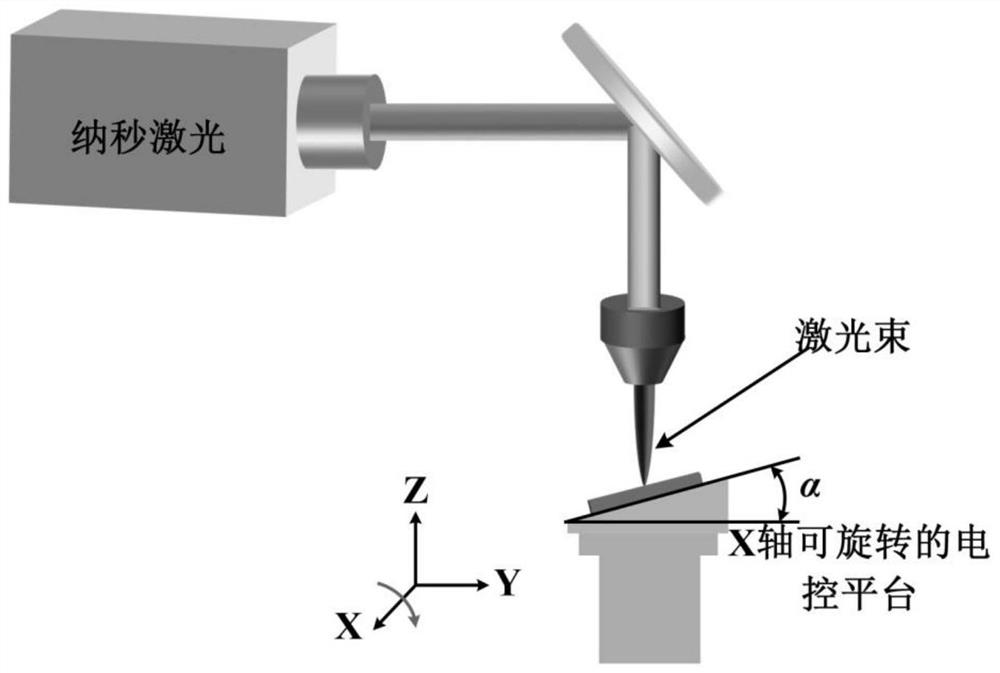

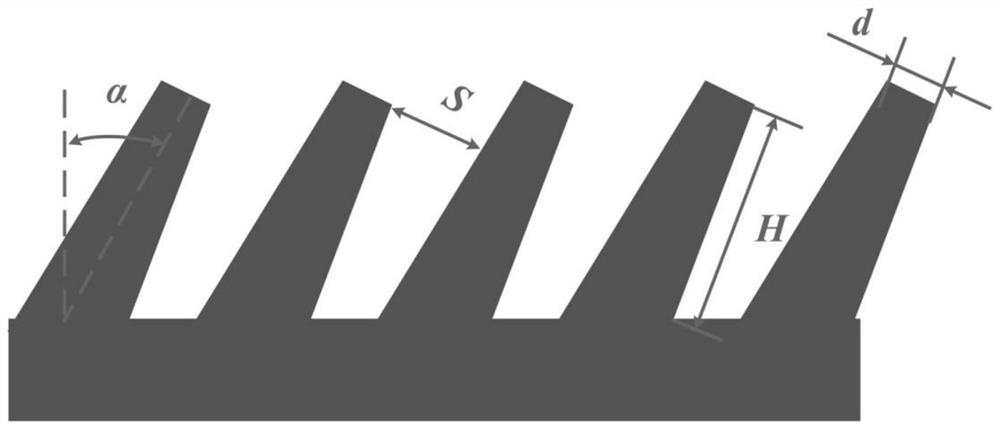

[0029] Using nanosecond laser processing droplet lateral cake-shaped bouncing superhydrophobic slanted pillar array, such as figure 1 As shown, the specific method is as follows:

[0030] In the first step, the nanosecond laser processes the slanted column array:

[0031] 1.1) Polish the 1060 aluminum plate (thickness 3mm) with 800# and 1500# sandpaper in order, and then ultrasonically clean it with deionized water to remove surface oil and dust;

[0032] 1.2) Nanosecond laser processing aluminum plate to construct micro / nano structure, processing power is 21W, scanning speed is 700mm / s, scanning frequency is 20kHz, filling line spacing is 50μm, scanning times is 1;

[0033] 1.3) Draw the scanning trajectory of the nanosecond laser: draw a rectangle with a width of 0.5mm and a length of 9mm, draw a 20×1 circular array with a gap of 200μm inside and a diameter of 250μm, the circular area is not filled, and the outer area of the circle is drawn Filling, the filling line spac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com