A kind of high permeability interfacial reinforcement agent

A reinforcing agent and high-permeability technology, applied in the direction of coating, etc., can solve the problems of difficult film formation, slow drying speed, poor adhesion and durability, etc., and achieve the effect of fast film forming speed, small particle radius and good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A high-penetration interface strengthening agent, calculated in parts by mass, is prepared from the following raw materials: 50% of deionized water, 10% of styrene, 18% of isobutyl propylene, 4% of isooctyl propylene, 1% of functional monomer, Silane coupling agent 0.2%, emulsifier 0.8%, sodium persulfate 0.4%, post-treatment agent 0.2%, lithium silicate 15%, pH adjuster 0.07%, defoamer 0.03%, bactericide 0.3%.

example 1

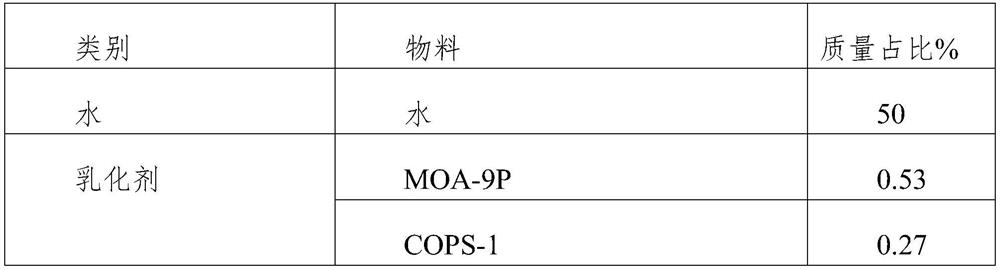

[0034] Example 1 Ingredient List:

[0035]

[0036]

[0037] The preparation steps are as follows:

[0038] Step 1: Preparation of core emulsion: add 20% deionized water and emulsifier to the emulsification tank, start stirring and dispersing for 15 minutes, add styrene, alkyl acrylate, functional monomer, and continue stirring for 15 minutes, that is, have to;

[0039] Step 2: Shell segment solution preparation: add 10% deionized water, inorganic silicate, and silane coupling agent to the emulsification tank, and disperse with a mixer for 1 hour at room temperature to obtain;

[0040] Step 3: Preparation of reactor bottom material: add 10% deionized water and emulsifier to the reactor to obtain the reactor bottom material;

[0041] Step 4: Heat the reaction kettle to 89°C. After adding the initiator, the remaining initiator and the core segment emulsion are separately added dropwise for 2 hours, and the medium is kept for 30 minutes, and then the shell segment solutio...

Embodiment 2

[0043]A high-penetration interface strengthening agent is characterized in that, in terms of mass ratio, it is made from the following raw materials: 60% deionized, 10% styrene, 15% butyl acrylate, 2% functional monomer, silane Coupling agent 0.5%, emulsifier 1.2%, initiator 0.5%, post-treatment agent 0.25%, inorganic silicate 10%, pH adjuster 0.02%, defoamer 0.03%, bactericide 0.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration depth | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com