Preparation method of bio-based flame-retardant and light-aging-resistant PVA (Polyvinyl Alcohol) composite material

A composite material, anti-light aging technology, applied in the field of composite materials, can solve the problem of reducing the performance of polymer materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

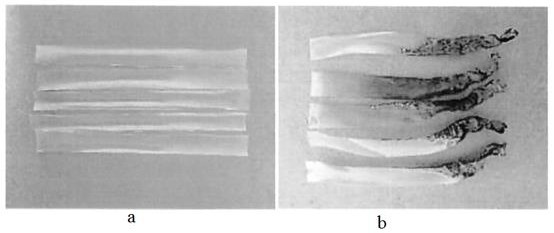

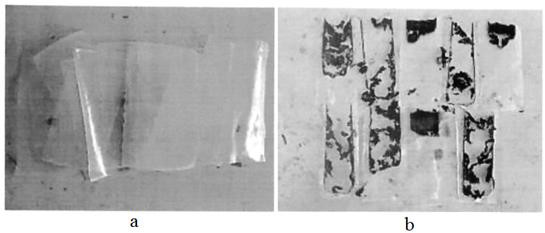

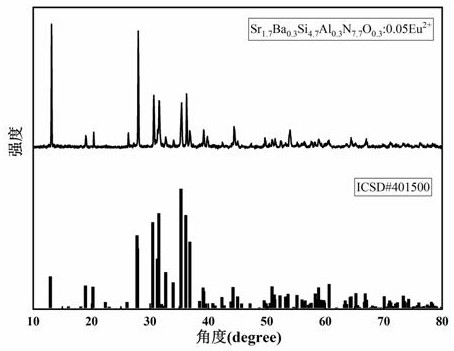

[0035] Disperse 2 g of polyvinyl alcohol with a degree of polymerization of 1750 in 100 mL of deionized water, raise the temperature to 80 ° C, stir for 1 h, and naturally cool to room temperature to obtain a PVA dispersion; add 0.5 mL of glacial acetic acid and 0.1 g of PVA dispersion to 100 mL of PVA dispersion Chitosan powder was stirred at room temperature for 2 hours until the chitosan powder was completely dissolved to obtain a mixed solution; 0.25 g of phytic acid was added to the mixed solution, stirred at room temperature for 1 hour, and then ultrasonicated for 1 hour to obtain a bio-based flame-retardant PVA solution ; Add phosphor powder excited in the 200nm to 400nm band to the bio-based flame-retardant PVA solution, the quality of the added phosphor is 3% of the bio-based flame-retardant PVA solution and the phosphor powder, stir at room temperature for 4 hours, and then sonicate for 1 hour , to obtain a mixed solution; the mixed solution was transferred to a mold ...

Embodiment 2

[0037] Disperse 5 g of polyvinyl alcohol with a degree of polymerization of 1750 in 250 mL of deionized water, raise the temperature to 95 ° C, stir for 3 hours, and naturally cool to room temperature to obtain a PVA dispersion; add 2 mL of glacial acetic acid and 1 g of chitosan to 250 mL of the PVA dispersion Sugar powder was stirred at room temperature for 4 hours until the chitosan powder was completely dissolved to obtain a mixed solution; 8 g of phytic acid was added to the mixed solution, stirred at room temperature for 2 hours, and then ultrasonicated for 4 hours to obtain a bio-based flame-retardant PVA solution; The bio-based flame-retardant PVA solution is added with fluorescent powder that is excited in the 200nm-400nm band, the quality of the added phosphor is 5% of the total mass of the bio-based flame-retardant PVA solution and the phosphor powder, stirred at room temperature for 6 hours, and then ultrasonicated for 2 hours. A mixed solution was obtained; the mix...

Embodiment 3

[0039] Disperse 3.5g of polyvinyl alcohol with a degree of polymerization of 1750 in 175mL of deionized water, raise the temperature to 87.5°C, stir for 2 hours, and naturally cool to room temperature to obtain a PVA dispersion; add 1.25mL of glacial acetic acid and 0.55 g chitosan powder, stirred at room temperature for 3 hours until the chitosan powder was completely dissolved to obtain a mixed solution; 4.125 g of phytic acid was added to the mixed solution, stirred at room temperature for 1.5 hours, and then ultrasonicated for 2.5 hours to obtain a biobased barrier solution. Burn the PVA solution; add phosphor powder that is excited in the 200nm to 400nm band to the bio-based flame-retardant PVA solution, the quality of the added phosphor is 4% of the total mass of the bio-based flame-retardant PVA and the phosphor powder, and stir at room temperature for 5 hours , and then sonicated for 1.5 hours to obtain a mixed solution; the mixed solution was transferred to a mold and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com