High-toughness conductive nano composite ionic gel and preparation method thereof

A technology of conductive nano-composite ions, which is applied in the field of high-toughness conductive nano-composite ion gels and its preparation, can solve the problems of ion gel extensibility and low conductivity, which cannot meet practical applications and are not suitable for large-scale production. Achieve the effects of moderate interaction, improved conductivity and improved elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

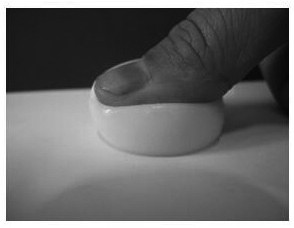

Embodiment 1

[0061] Take 5 ml of nano-TiO with an average particle size of 10 nm and a mass concentration of 10% 2 The sol and 35 ml of ionic liquid 1-methyl-3-butylimidazolium hexafluorophosphate were added to a round bottom flask, and magnetically stirred for 30 min to obtain uniform nano-TiO 2 Dispersions. Add 0.02 mol acrylamide and 0.02 mol N-isopropylacrylamide to the above dispersion, stir for 40 minutes under the condition of helium, add 0.1 g initiator ammonium persulfate, 25 mg catalyst N, N, N' , N'-tetramethylethylenediamine, after stirring evenly, transferred to molds of different shapes, sealed, and free radical polymerization at 80°C for 4 hours. After the polymerization, the samples were taken out, placed in vacuum drying at 80°C and dried for 6 hours to constant weight to obtain spherical samples and strip samples of conductive nanocomposite ion gels with high toughness, wherein the spherical samples had a diameter of 2 cm. The strip sample has a length of 10 cm and a d...

Embodiment 2

[0068] Take 10 ml of nano-TiO with an average particle size of 15 nm and a mass concentration of 10% 2 The sol and 40 ml of ionic liquid 1-methyl-3-butylimidazolium tetrafluoroborate were added to a round bottom flask, and magnetically stirred for 30 min to obtain uniform nano-TiO 2 Dispersions. Add 0.01 mol acrylic acid and 0.04 mol N, N-dimethylacrylamide to the above dispersion, stir for 30 minutes under the condition of blowing nitrogen, add 0.15 g initiator potassium persulfate, 20 mg catalyst N, N, N', N'-tetramethylethylenediamine, after being stirred evenly, was transferred into molds of different shapes, sealed, and subjected to radical polymerization at 60° C. for 8 hours. After the polymerization, the samples were taken out, placed in vacuum drying at 80°C and dried for 4 hours to constant weight to obtain spherical samples and strip samples of conductive nanocomposite ion gels with high toughness, wherein the spherical samples had a diameter of 2 cm. The diamete...

Embodiment 3

[0071] Take 15 ml of nano-TiO with an average particle size of 20 nm and a mass concentration of 15 % 2 Add the sol and 25 ml ionic liquid 1-ethyl-3-methylimidazolium acetate into a round-bottomed flask, and mix with magnetic stirring for 30 min to obtain uniform nano-TiO 2 Dispersions. Add 0.04 mol acrylic acid and 0.08 mol 2-hydroxyethyl acrylate to the above dispersion, stir for 60 minutes under the condition of nitrogen, add 0.58 g initiator sodium persulfate, 60 mg catalyst N, N, N', N '-Tetramethylethylenediamine, after being evenly stirred, transferred to molds of different shapes, sealed, and radically polymerized at 40°C for 12 hours. After the polymerization, the samples were taken out, placed in vacuum drying at 80°C for 5 hours to constant weight, and spherical samples and strip samples of conductive nanocomposite ion gels with high toughness were obtained, wherein the spherical samples had a diameter of 2 cm. The strip sample has a length of 10 cm and a diamete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com