Cold rolling equipment for thinning aluminum foil for double-sided photocell tab

A photovoltaic cell and double-sided technology, applied in electrode rolling/calendering, workpiece surface treatment equipment, electrode manufacturing, etc., can solve problems such as unfavorable processing, difficult clamping and fitting in automatic operation, and poor forming performance, so as to improve the pressure resistance and orientation, increase the effect of dust removal and dust removal, and improve mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

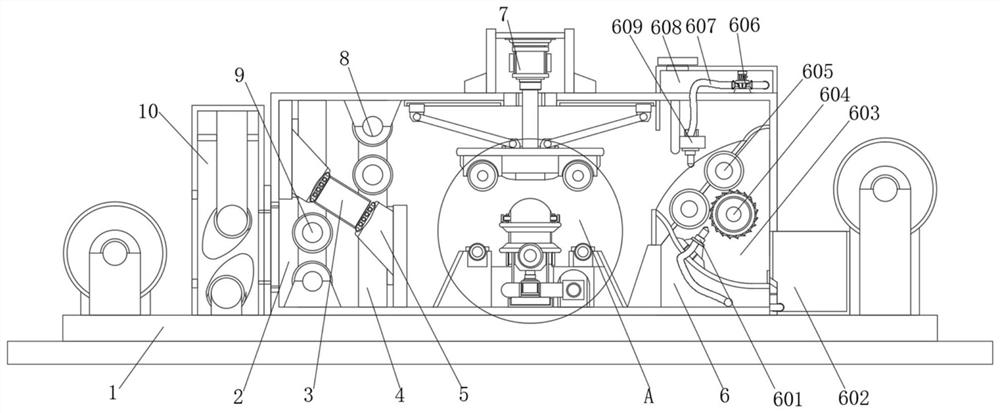

[0038] Example 1, such as figure 1 and Figure 4 As shown, when the aluminum foil passes through the opposite sides of the second cold roll 15 and the first cold roll 12, the start of the servo motor 147 can drive the two-way screw mandrel 148 to rotate, and the two-way screw mandrel 148 rotates to force two groups of internal threads to rotate. The tubes 149 move close to each other, so that the inner threaded tube 149 drives the two sets of limit discs 145 at the same end of the fixed seat 141 to contact each other on the sides of the aluminum foil. At this time, the electric push rod 142 is activated to lift the fixed block 143. With the cooperation of the sleeve column 146, it rises, forcing the two sets of limit discs 145 at the same end to come into close contact with each other, and squeeze and fit the sides of the aluminum foil, and then limit the side of the aluminum foil to prevent the aluminum foil from being deformed during cold rolling. Two sets of guide rollers ...

Embodiment 2

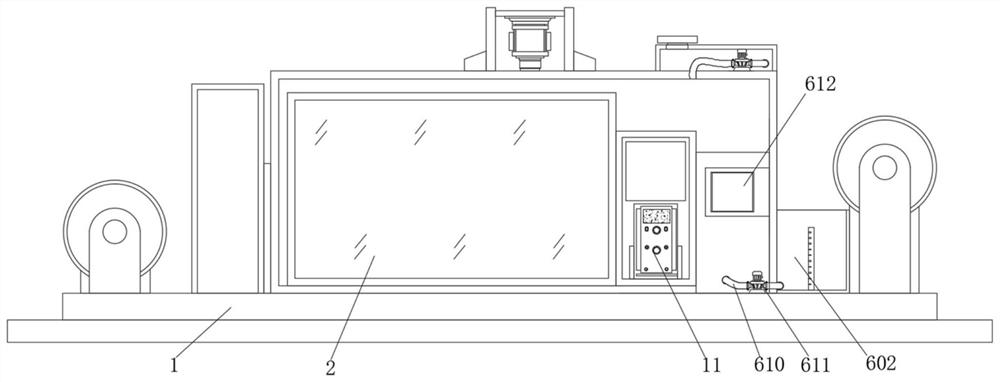

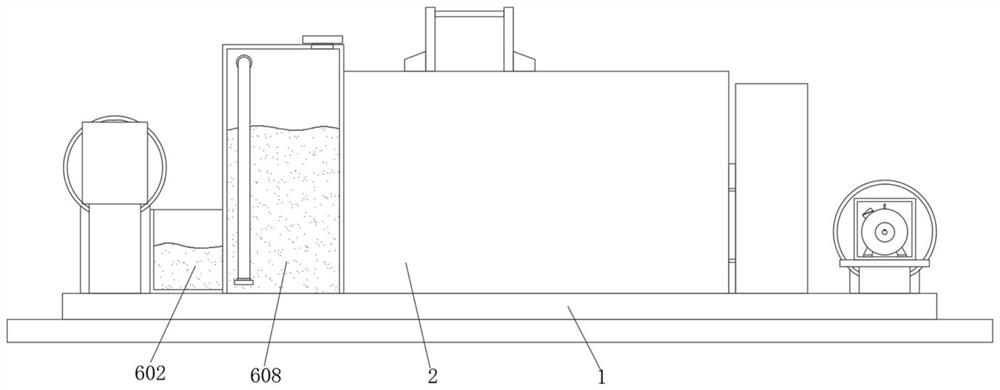

[0039] Example 2, such as figure 1 and Figure 7 As shown, when the aluminum foil is conveyed through the two sets of pressure rollers 605, the degreasing agent is put into the water tank 608 and mixed with the water liquid, and the water liquid in the water tank 608 can be pumped out by starting the first water pump 606, and cooperate with the diversion The diversion of the pipe 607 guides the water into the second spraying mechanism 609 for spraying, and then sprays and cools the top of the aluminum foil, and the cooled water can enter the receiving tank 602 to accumulate under the diversion of the structure of the diversion frame 603 At this time, through the water liquid in the flow tank 602, the water liquid in the flow tank 602 is drawn out and introduced into the first spraying mechanism 601 by the start of the second water pump 611 under the guidance of the catheter tube 610, and then sprayed on the aluminum foil. The lower part is sprayed to cool down, and at the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com