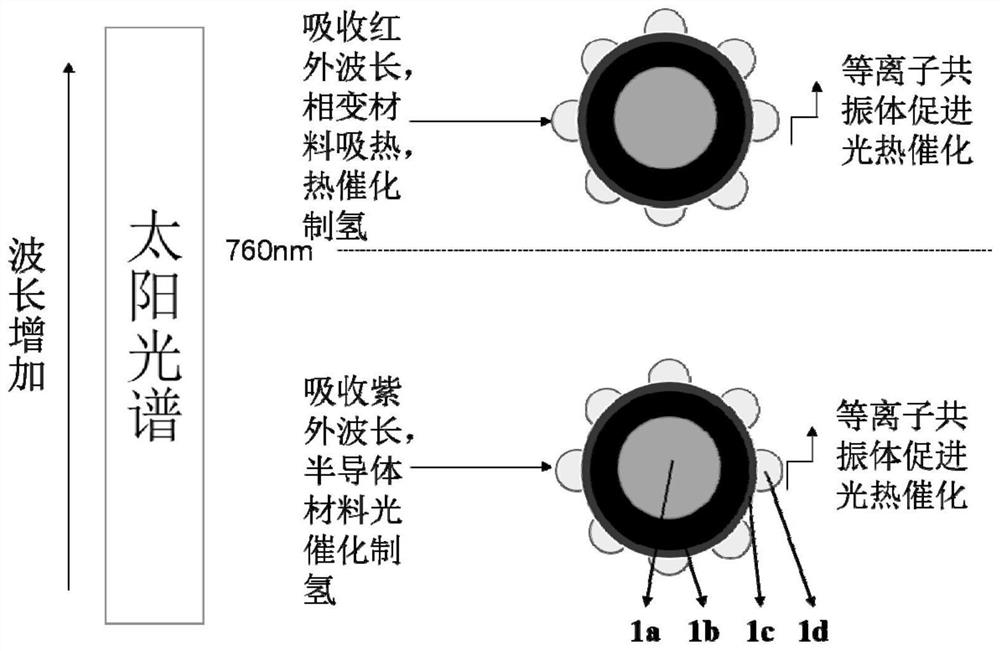

Photo-thermal synergistic catalytic hydrogen production microcapsule and preparation and application thereof

A technology of photothermal synergy and microcapsules, applied in chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problems of inability to produce hydrogen, limited hydrogen production efficiency, Hydrogen efficiency limitations and other issues, to achieve the effect of improving hydrogen production efficiency, improving photocatalytic efficiency, and preventing clusters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

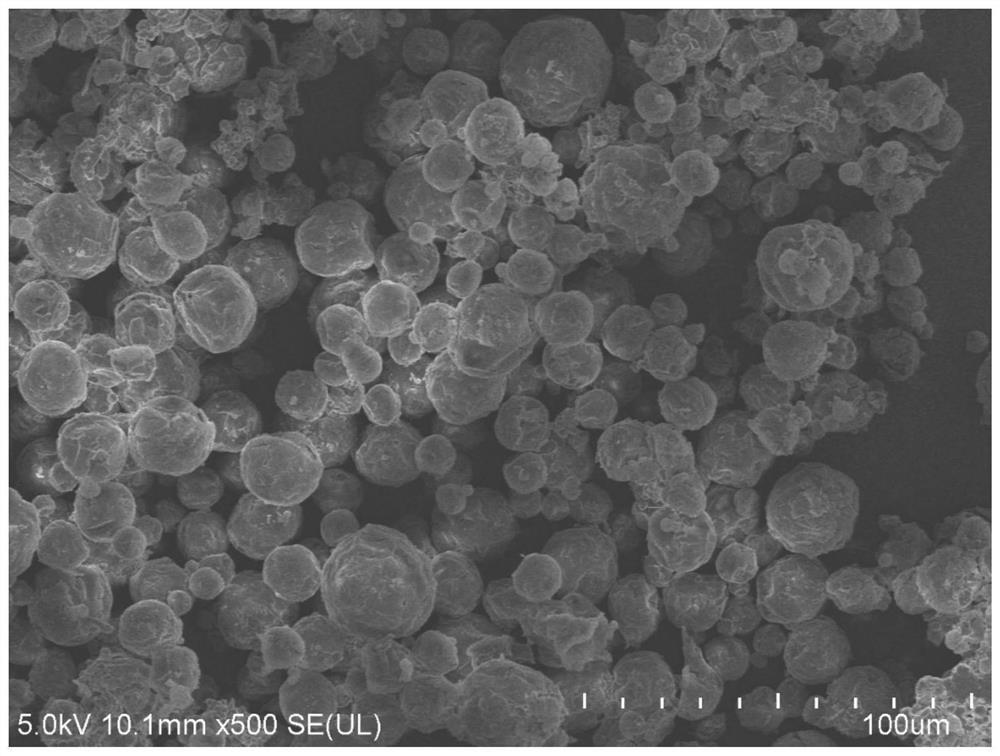

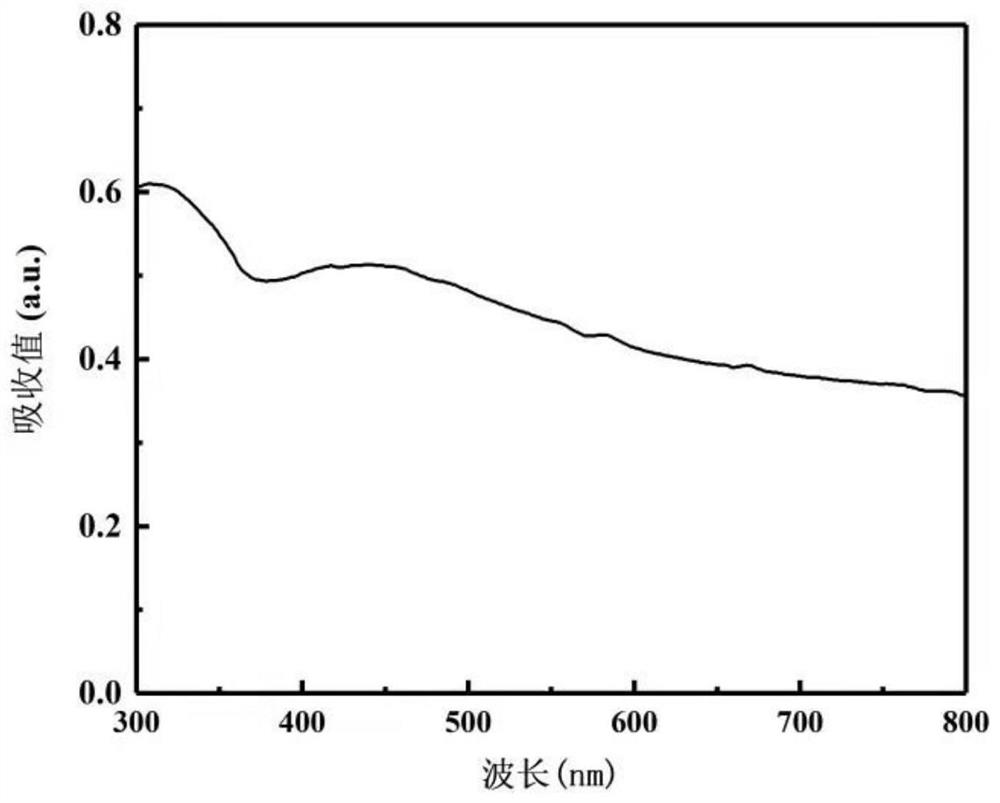

[0053] Example 1 A preparation method of photothermal synergistic catalytic hydrogen production microcapsules

[0054] 1. Experimental method

[0055] S1. Disperse 5g eicosane into 10ml aqueous solution containing Tween (mass fraction is 2%), mix ethyl orthosilicate and aminopropyl triethoxysilane (ethyl orthosilicate, aminopropyl triethoxysilane) The mass ratio of ethoxysilane and eicosane is 0.16:0.19:1) dispersed in 20mL toluene solution containing Span 80 (mass fraction is 1%), and then the toluene solution is injected dropwise into the above aqueous solution to Stir and emulsify at a temperature of 80°C for 4 hours at a rotation speed of 500rpm to obtain the phase-change microcapsules of the core-shell structure; take butyl titanate (the mass ratio of eicosane is 4:1), and make the core-shell structure The phase change microcapsules were ultrasonically stirred in butyl titanate at a speed of 1000rpm for 0.1h, and the hydrothermal method was used at 140°C. After 20h, semi...

Embodiment 2

[0062] Example 2 A preparation method of photothermal synergistic catalytic hydrogen production microcapsules

[0063] 1. Experimental method

[0064] S1. 5g hexadecane is dispersed in the 10ml aqueous solution that contains cetyltrimethylammonium chloride (mass fraction is 1%), orthosilicate ethyl and triethoxyfluorosilane (orthosilicate ethyl The mass ratio of ester, triethoxyfluorosilane and hexadecane is 0.1:0.7:1) and dispersed in 20mL chloroform solution containing Span 80 (5% mass fraction), and then inject the chloroform solution dropwise into the above Stir and emulsify in an aqueous solution at a speed of 1500rpm at a temperature of 40°C for 1 hour to obtain the phase-change microcapsules of the core-shell structure; take sodium tungstate (mass ratio to hexadecane is 1:1), Ultrasonically stir the phase change microcapsules with core-shell structure in sodium tungstate at a speed of 500rpm for 1h, and use hydrothermal method at 230°C to obtain semiconductor-wrapped d...

Embodiment 3

[0068] Example 3 A preparation method of photothermal synergistic catalytic hydrogen production microcapsules

[0069] 1. Experimental method

[0070] With the experimental method of Example 1, the difference is that tetramethoxysilane is used to replace ethyl orthosilicate, octadecyl alcohol is used to replace eicosane, tetramethoxysilane, aminopropyltriethoxysilane and octadecyl The mass ratio of alcohol is 1.4:0.1:1, Tween is replaced by sodium lauryl sulfate, and the mass fraction of sodium lauryl sulfate is 5%, and toluene is replaced by cyclohexane.

[0071] 2. Experimental results

[0072] Disperse the photothermal synergistically catalyzed hydrogen production microcapsules into a 30% glycerin solution, stir at a speed of 500rpm for 0.5h at a temperature of 60°C and a pressure of 0.1MPa, illuminate with simulated solar xenon light, and calculate rate of hydrogen production.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com