Unilateral electrode ionic polymer pressure sensing array and preparation method thereof

An ionic polymer and side electrode technology, applied in the field of single-side electrode ionic polymer pressure sensing array and its preparation, can solve the problems of unstable contact, little research, noise interference, etc., so as to improve the reliability of the device and simplify the device structure, the effect of reducing the difficulty of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] The preparation method of ionomer film is as follows:

[0060] Use copper sheet or frosted glass as the mold for casting film, use DuPont's 5% to 20% concentration of Nafion solution, and dimethylacetamide according to the ratio of (1 to 4): 1, and obtain 25% to 33% by concentration. % of the concentrated solution is used for casting film;

[0061] Coat the casting solution on the surface of the mold, place it in a vacuum drying oven, and dry it at a high temperature of 60-80°C to make the solution solidify and form a film;

[0062] The copper sheet and the membrane were placed in deionized water, and the membrane was removed under the assistance of ultrasound to obtain an ionic polymer film with a pyramid microarray structure.

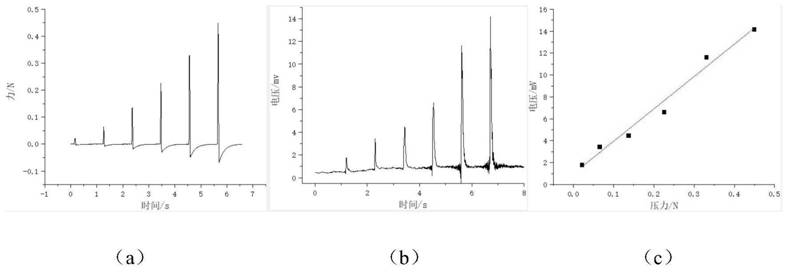

Embodiment 1

[0065] A laser-brushed copper sheet is used as a mold for casting a film. DuPont's 5% Nafion solution is used to prepare a 4:1 ratio of dimethylacetamide, and a 25% concentrated solution is obtained through concentration for casting a film. The casting solution is coated on the surface of the mold, placed in a vacuum drying oven, and dried at a high temperature of 80°C to make the solution solidify and form a film. Place the copper sheet and membrane in deionized water, and remove the membrane under the assistance of ultrasound to obtain an ionic polymer film with a pyramidal microarray structure, such as figure 2 shown.

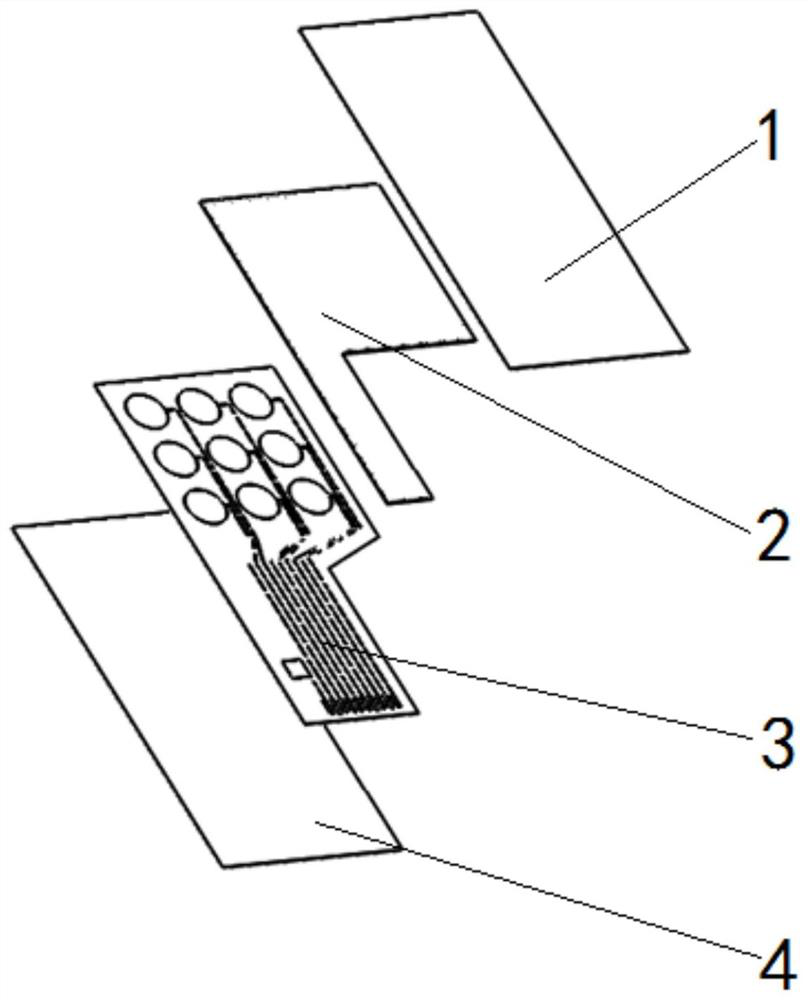

[0066] see image 3 , the flexible fpc circuit board is used as the electrode layer, and the fpc connector is connected to the conditioning circuit through the end of the electrode layer. When assembling, refer to figure 1 First, the double-sided adhesive layer 4 is bonded to the surface of the object to be measured, then the electrode layer 3 is bonded,...

Embodiment 2

[0070] Use the laser-brushed copper sheet as the casting mold, use DuPont's 10% Nafion solution, and dimethylacetamide according to the ratio of 2:1, and obtain a 28% concentrated solution for casting the film through concentration; The casting solution is coated on the surface of the mold, placed in a vacuum drying oven, and dried at a high temperature of 65°C to make the solution solidify and form a film. Place the copper sheet and membrane in deionized water, and remove the membrane under the assistance of ultrasound to obtain an ionic polymer film with a pyramidal microarray structure, such as figure 2 shown.

[0071] see image 3 , the flexible fpc circuit board is used as the electrode layer, and the fpc connector is connected to the conditioning circuit through the end of the electrode layer. When assembling, refer to figure 1 First, the double-sided adhesive layer 4 is bonded to the surface of the object to be measured, then the electrode layer 3 is bonded, the ion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com