Assistant for improving heat absorption performance of PET polyester chip and production method of PET bottle

A polyester chip, heat-absorbing technology, used in the production of additives and PET bottles, can solve problems such as reducing the L value and affecting the visual appearance of PET containers, achieving excellent thermal stability, and more bluish appearance and appearance. Excellent phase and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The invention proposes an auxiliary agent for improving the heat-absorbing performance of PET polyester chips, which is formed by adding titanium nitride or zinc nitride to the auxiliary agent to form a mixed auxiliary agent.

[0026] The present invention also proposes a kind of production method of PET bottle, comprises the following steps:

[0027] Step 1: Mix titanium nitride or zinc nitride with one or both of ethylene glycol and isobutanol to form a mixed solution;

[0028] Step 2: Stir the purified terephthalic acid and ethylene glycol in the slurry mixing tank according to the set density or molar ratio, pump them into the slurry feeding tank, and the slurry feeding tank enters through the pump through the slurry injection nozzle In the esterification tank, under the temperature condition of 265°C±5°C, the slurry is homogeneously mixed and reacted in the esterification tank to obtain oligomers; the by-products and oligomers after the reaction are separated throu...

Embodiment 2

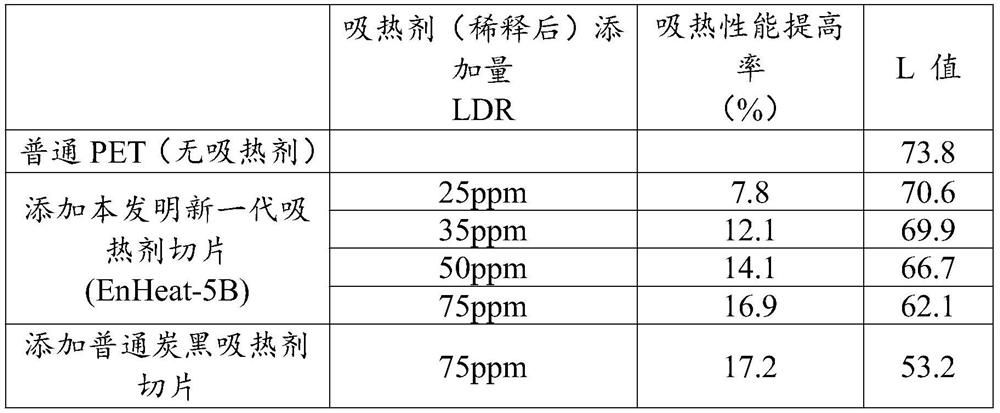

[0039] Another domestic slicing factory tested slices without adding any endothermic agent, adding ordinary carbon black endothermic agent, and adding slices of the present invention. The power consumption performance was compared.

[0040] Table 2 Comparison of power consumption for blowing of preforms with different slices

[0041]

[0042] Compared with ordinary slices without adding heat-absorbing agent, the slices added with the high heat-absorbing agent of the present invention can save more than 35% of energy consumption. And it has a higher transparent appearance than carbon black heat absorbing slices.

Embodiment 3

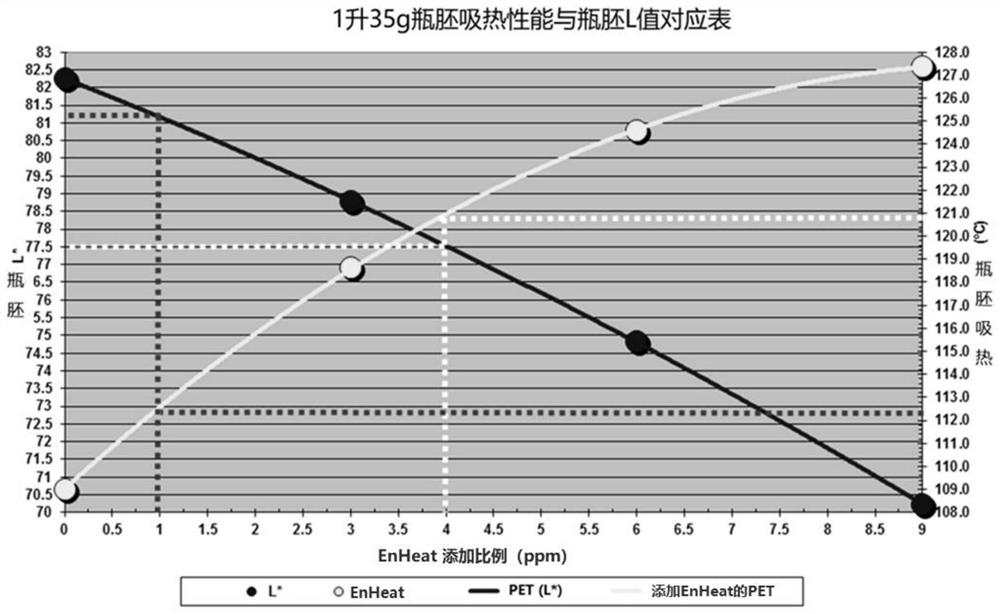

[0044] The test verifies the change of the L value (brightness) of the slice with the increasing proportion of the heat absorbing agent, so as to find a reasonable adding range that can balance the heat absorbing performance and appearance brightness of PET.

[0045] Such as figure 1 As shown, within the effective addition range of 2-6ppm, the heat absorption performance and appearance brightness requirements of slices can be better balanced. Preferably, the addition of active ingredients at 3-5ppm is a recommended reasonable addition ratio.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com