Novel heat absorber of tower-type photo-thermal power station

A technology of photothermal power stations and heat absorbers, applied in the mechanical field, can solve problems such as radiation heat loss, achieve the effects of reducing brightness, reducing unit heat load, and reducing light pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Such as figure 1 As shown, the vertical heat-absorbing panels in the current tower-type heat absorber are single-row radiation heat-absorbing tube panels perpendicular to the ground, which are generally arranged in a single row. When the light reflected by the heliostat shines on the heat-absorbing panel , part of the light is not absorbed by the heat-absorbing screen but is reflected, so the heat-absorbing device is very bright when viewed from a distance, and when the temperature of the heat-absorbing screen is high, its radiated heat is a large loss.

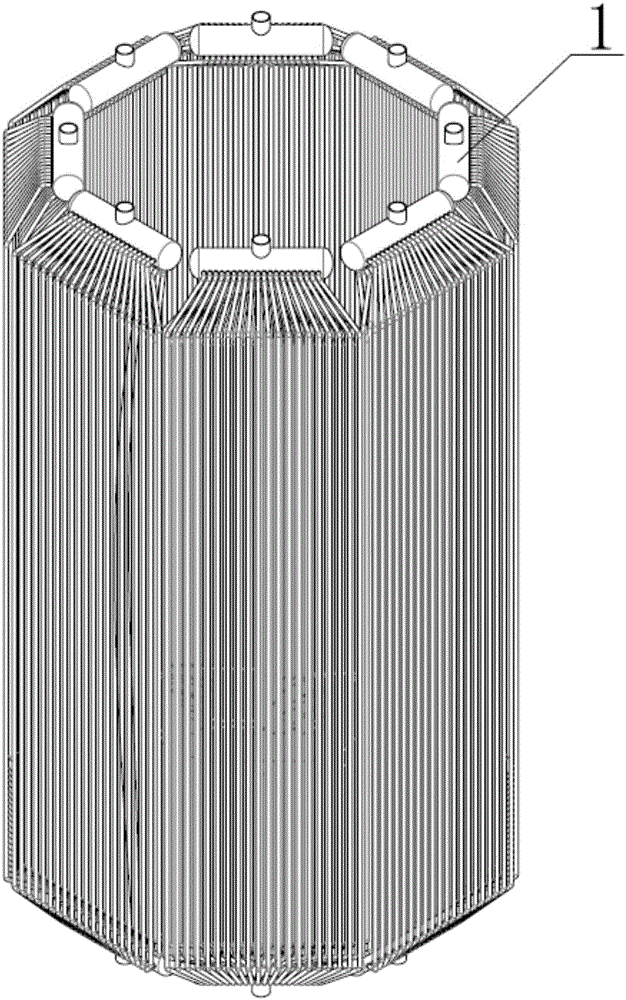

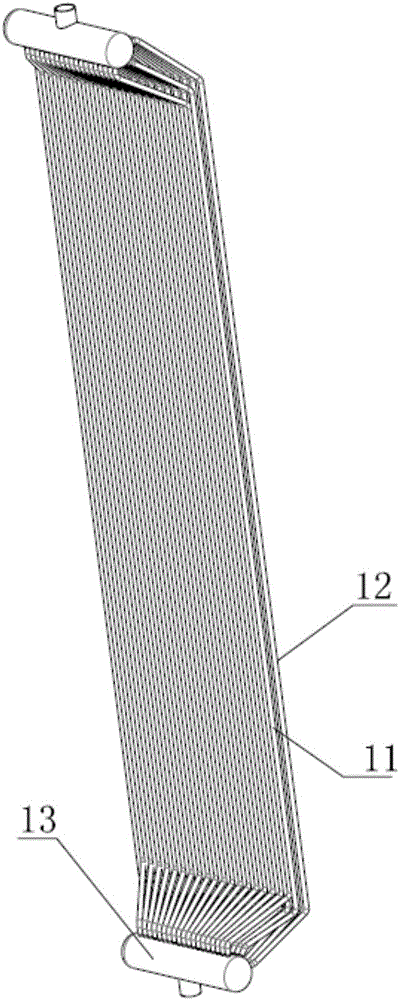

[0027] Such as Figure 2-5 As shown, it is a new type of tower-type photothermal power station heat absorber of the present invention, the heat absorber is composed of a plurality of heat absorber units 1, and the plurality of heat absorber units 1 are arranged along the direction of the tower circumference, in the form of Circular or polygonal, the heat absorber unit 1 includes: a first heat absorbing tube panel 11, ...

Embodiment 2

[0030] Such as Figure 6 As shown, this embodiment is basically the same as the above-mentioned embodiment, the only difference is that a third heat-absorbing tube panel 13 is provided on the side opposite to the first heat-absorbing tube panel 11 of the second heat-absorbing tube panel 12, The third heat-absorbing tube panel 13 includes a plurality of third tube bodies 131 arranged at equal intervals, and the number ratio of the third tube bodies 131 to the second tube bodies 121 is 1:1.5˜1:4.

Embodiment 3

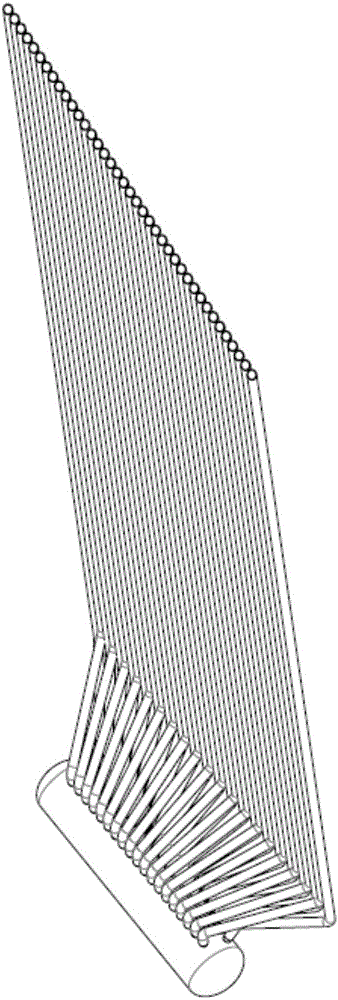

[0032] Such as Figure 7 As shown, this embodiment is basically the same as the above-mentioned embodiment, the only difference is that a fourth heat-absorbing tube panel 14 is also provided on the side opposite to the second heat-absorbing tube panel 12 of the third heat-absorbing tube panel 13, The fourth heat absorbing tube panel 14 includes a plurality of fourth tube bodies 141 arranged at equal intervals, and the ratio of the number of the fourth tube bodies 141 to the third tube bodies 131 is 1:1.5˜1:4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com