Continuous gradient bionic manufacturing method based on pneumatic accurate control active cartilage scaffold

A manufacturing method and cartilage technology, applied in processing and manufacturing, manufacturing tools, additive manufacturing, etc., can solve the problems of single concentration, single composition, inconsistent anatomical characteristics, etc., achieve precise control, improve time lag, and facilitate adhesion and reproductive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

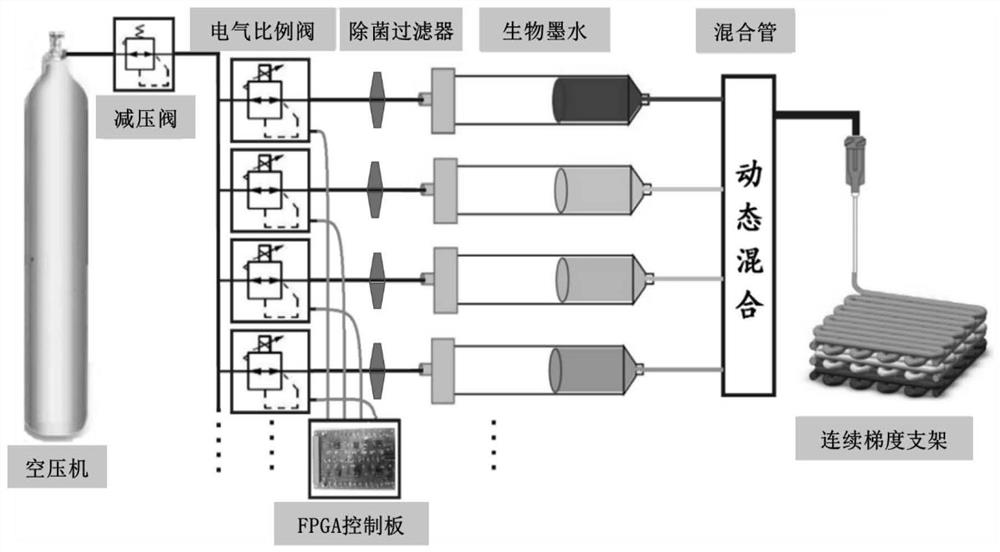

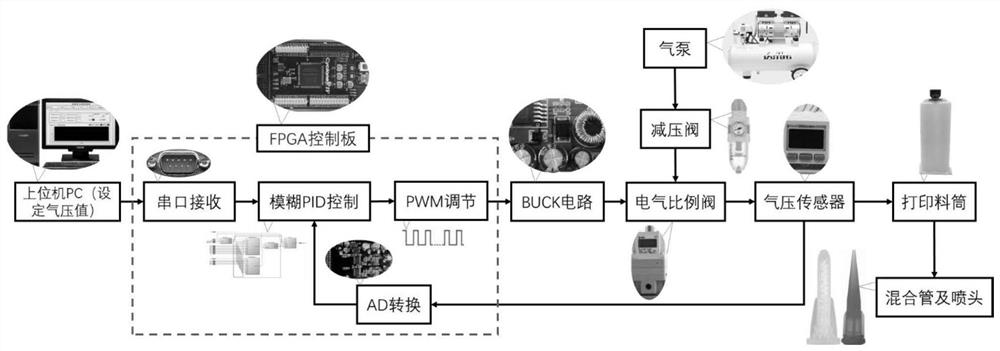

[0046] The present invention aims at the problem that the concentration of the existing cartilage scaffold material is single, the material composition of each layer in the layered structure is single, etc., which do not conform to the anatomical characteristics of the continuous gradient of natural cartilage, based on sodium alginate (SA) ion crosslinking and gelatin (Gel) Solidification forming mechanism, using SA, Gel, hydroxyapatite (HA) and chondrocyte suspension as the scaffold matrix material, according to the morphological characteristics of natural soft tissue, using extrusion deposition 3D printing technology based on high-pressure controllable gas to realize embedded living Preparation of three-dimensional soft scaffolds for cells. During the preparation process, the real-time dynamic and precise control of the pressure applied by different barrels is used to achieve precise and controllable component content, and then the real-time dynamic mixing and continuous grad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com