Palladium-coated copper bonding wire and method for manufacturing same

A manufacturing method and a bonding wire technology, which are applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve the problems of being cheaper than gold and improving characteristics, and achieve the effect of maintaining bonding reliability and excellent bonding reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0120] Next, examples will be described. The present invention is not limited to the following examples. Examples 1-19 and Examples 32-34 are examples, and Examples 20-31 are comparative examples.

example 1~18

[0122] Copper (Cu) with a purity of 99.99% by mass or more was used as a core material, which was continuously cast, rolled while performing pre-heat treatment, and then drawn once to obtain a copper wire rod (0.5 mm in diameter).

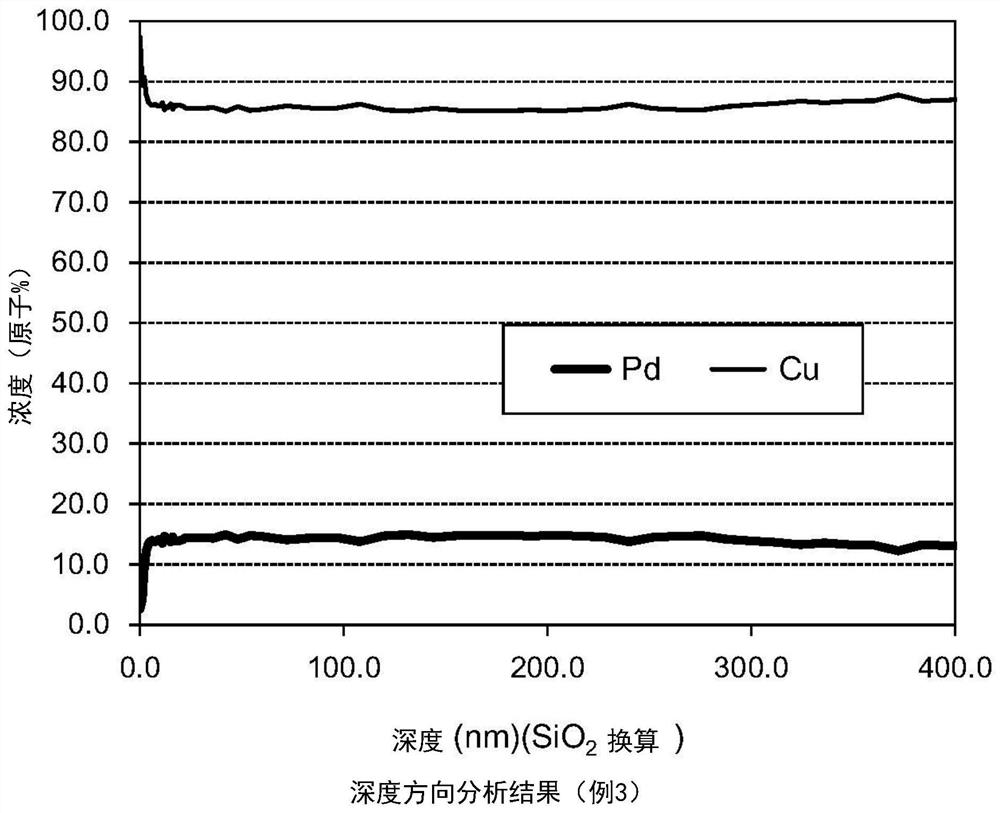

[0123] The palladium coating layer was formed as follows. Add additives containing sulfur, selenium, and tellurium to a commercially available palladium plating bath, and control the plating bath so that the concentration relative to the entire lead (total of copper, palladium, and chalcogen elements) becomes the concentration described in the table below. Concentrations of sulfur, selenium, and tellurium in the plating baths were prepared respectively. In the state where the copper wire is immersed in the plating bath, the current density of the copper wire is 0.75A / dm 2 Passing an electric current creates a palladium coating containing sulfur, selenium or tellurium. In the case of forming a palladium coating containing two or more of sulfur, se...

example 33~35

[0148] Next, the characteristics of the palladium-covered copper bonding wire having the gold layer on the palladium layer were confirmed. In the manufacturing process of the palladium-coated copper bonding wires of Examples 1, 4, and 7, after covering palladium, further using a commercially available gold plating bath to perform gold plating, the same operation as Examples 1, 4, and 7 was performed to produce The palladium of the gold layer covers the copper bonding wire (Examples 33-35). In addition, the concentration of each element in Table 3 was calculated without including the gold concentration of the gold layer in the whole lead.

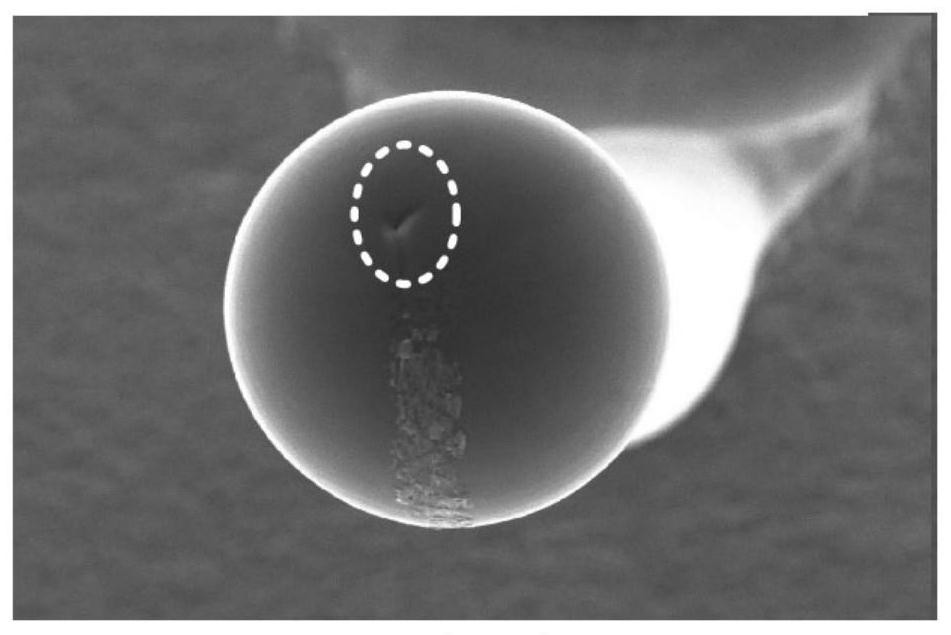

[0149] Die wear tests were performed on these palladium-coated copper bonding wires having a gold layer and the palladium-coated copper bonding wires of Examples 1, 4, and 7 without a gold layer, and the results are shown in the column of "die wear" in Table 3. middle. For the die wear test, the lead wire of each sample was continuously dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com