LEG type slipper bracket and manufacturing process thereof

A sliding shoe and supporting shoe technology, applied in the directions of bearings, shafts, coatings, etc., can solve the problems of unsatisfactory combination of alloy and matrix, difficult installation, high installation cost, cumbersome installation process, etc., so as to improve the efficiency of cold oil lubrication, combine Excellent performance, the effect of reducing the assembly cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

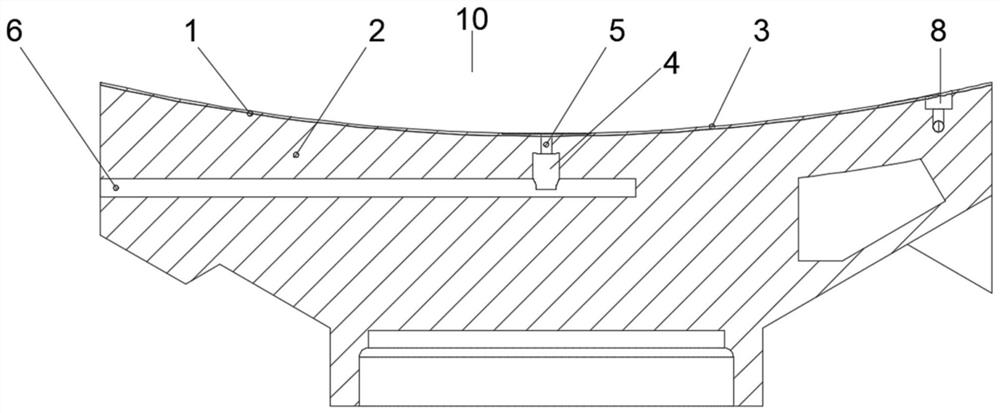

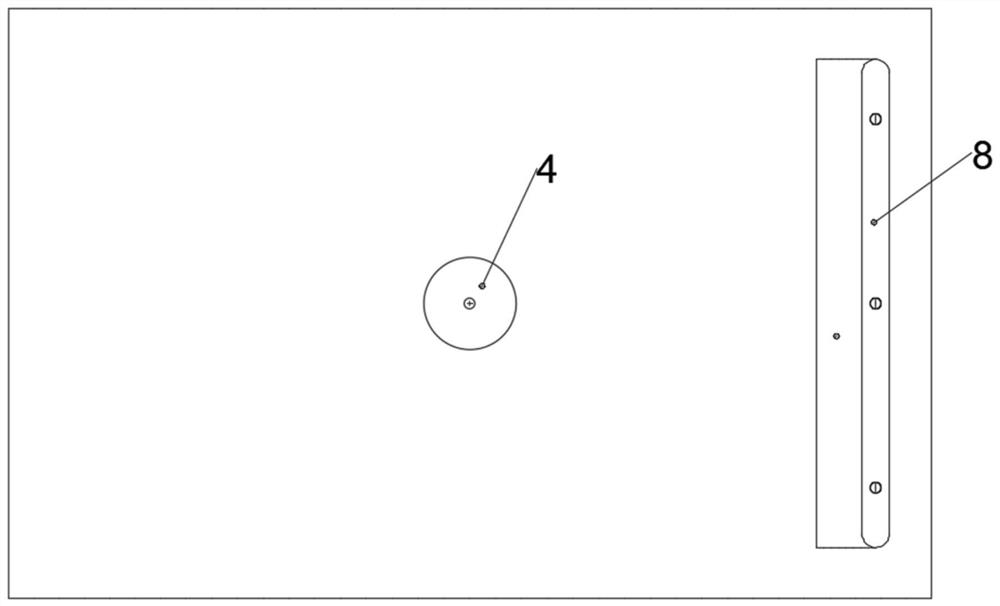

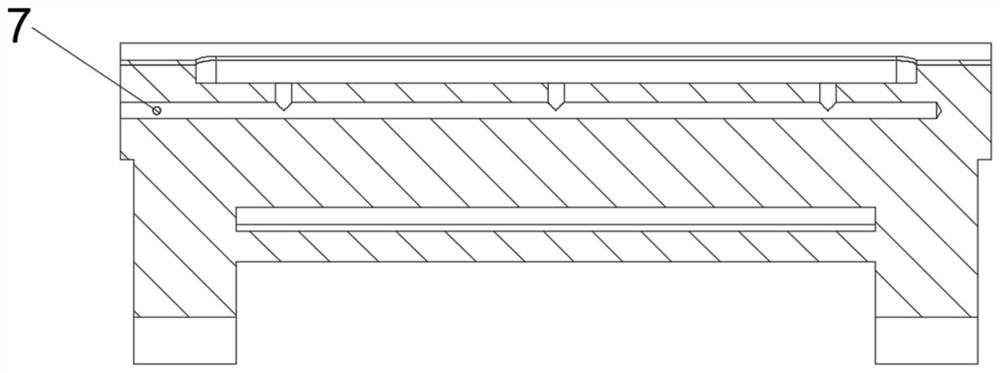

[0039] Refer to attached Figure 1-Figure 6 , a LEG type sliding shoe shoe and its manufacturing process provided by the present invention, including a sliding shoe shoe 10;

[0040] Further, the sliding shoe shoe 10 is composed of a tin-based Babbitt alloy layer 1 and a bearing base 2, and the tin-based Babbitt alloy layer 1 is clad on the bearing base 2 by arc deposition, and the tin-based Babbitt alloy layer 1 is clad on the bearing base 2 by arc deposition. The thickness of the babbitt alloy layer 1 is set to 3-4 mm, specifically, the thickness of the tin-based babbitt alloy layer 1 is preferably 3.5 mm.

[0041] Further, the inner wall of the top end of the be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com